HP Memories

I don't intend to tell you about all remaining 58 Microwave projects but will hit some of the high spots.

I know we weren't, but, speaking of computers, I've been totally sold on computers since they were first introduced. In the beginning, I had no idea what they did or how they did it but they were just mysteriously wonderful. I tried to follow various computer languages and the various models available on the market. I tried to understand the logic and various advantages of each computer language. Computer technology has always been a fast-moving and deep subject. Several of my lab co-workers were taking courses in computer science and programming languages at Stanford. I'd overhear their conversations of what they were studying and learning. I tried to understand the benefits of one computer language over another and a different language would pop up without warning. I always liked Basic and did a little programming in that language. I did understand how it worked. Before long someone came up with HP-Basic that was a little different but just as easy to understand. Then there was machine language and compilers and other mysterious technologies to understand. And it all continues on to this day.

Many of our new test instruments became programmable and could be remotely controlled to test and measure various parameters on a product. Back in the '80s the control signals and results were connected between the various instruments and computer by the HPIB (Hewlett-Packard Interface Bus). The computer controlled the various test instruments. The test results could then be printed out, displayed on the computer screen or stored in computer memory for further analysis. This was a boon to test instrumentation technology and has continued to become more and more sophisticated as time goes on. Many of the test instrumentation of today have built-in computers and microprocessors resulting in much simpler, real-time, more precise signal analysis and control.

|

HP 11715A |

Radio communication has always been important to HP. It seems that during this time there is more focus and/or more importance placed on transmitters, hand-held telephones, and later, cell phones and the fidelity and/or distortion of these devices. Cell phones were just in their blossoming stages and cell networks were just being planned, constructed and tested. My next few product activities were aimed at this blossoming new market.

In early 1980 I helped develop the 11715 AM/FM test source. This was a simple product from a design standpoint so the design went quite quickly. This test source provides a very flat, wide-bandwidth and low distortion amplitude or frequency modulated RF signals for testing receivers or test instruments. It's still in the Agilent catalog selling for $4,500.00 each.

In early 1980 test systems with the HPIB (Hewlett Packard Interface Bus) and computer control became very popular. More and more of the instruments designed after 1980 had the required HPIB circuits inside and the HPIB connector on the back panel. This made it simple to create automated test systems. As you recall my recent years were devoted to the 8662/3A synthesized signal generator and the 8903A audio analyzer design. Both of these products had that HPIB hardware and capability included.

|

HP 8901B and 11722 Sensor |

I provided some preliminary design on the 8901B modulation analyzer. It also included the HPIB hardware for computer control. After some preliminary layout and mockups Bob Waldron, a fellow product designer, completed the design and documentation. That all worked out well and Bob did a fine job.

While Waldron was working on the final design of the 8901B, I was assigned to design a remote sensor (11722A) to be used with the 8901B. This required an unusual package design. Our industrial designer, Peter Lee, came over to my house and we actually designed the outside shape using a redwood 4X4 and the table saw to cut and trim the redwood to be a comfortable fit for the hand. Our design made it aesthetically handsome and just large enough to accommodate the various parts this sensor must contain. It was a fun and efficient way to quickly come up with a final module design that would work. To make drawings and have parts made in the model shop would have taken weeks. Doing the design at my table saw took about three hours. Twenty-seven years later Agilent is still selling the 11722A for $4,000.00 each. From that 3D redwood model, I made the appropriate drawings to get a mold made to make final housing parts. It wasn't long till we released that instrument to production.

|

HP 8955A (Big Foot I) |

A little later, one of my contributions was to help design a transceiver test system the 8955A. It was called "Big Foot I". It is taking full advantage of the HPIB remote control of our instruments and the control of our instruments by a programmable computer. It would automatically step through all the tests required in the manufacture of transceivers such as cell phones, which technology was just getting started. It was a large system designed to support the required equipment and designed to provide an adequate work surface for the programmer and test technician. We wanted it to look nice, house all the equipment and be a comfortable place for the workers.

The 8956B is a user interface and important part of the 8955A (Big Foot) test system. This instrument includes a lot of microwave switches and connectors behind the flip-down panel on the right and pushbutton selection to control the various tests required when testing transceivers. This was a fun project and went together well. The Big Foot systems were later sent to Spokane Division to be made there.

Some products are quite simple to design. This next one is a Frequency Doubler. You put 500MHz in the input and get 1000MHz in the output. It consisted of a simple extrusion, a PC board, a couple covers and a couple type "N" connectors. I was asked to design and document this new Doubler HP-11721A. It didn't take long before it was introduced into production.

I could spend several pages discussing the 8770A. It turns out this began as an under the counter design. Rolly Hassun was the project leader of two new products called "Data Source" and "Arbitrary Carrier Synthesizer." Somehow Rolly knew that by combining the proper modules we could create and build an Arbitrary Waveform Synthesizer. As I understand it, this synthesizer could make about any waveform one could imagine. It was computer controlled and had a fine display to show the waveform. He told me that we could get this to market faster than the other two products we were working on. It was an easy design for me. Most of the hardware was invented and existing. There were some minor changes, software had to be written for the computer. Quite a bit of work went into the DAC design. Management accepted this new product. Julie McDonald saw it through environmental tests and it was quite successful.

After becoming familiar with the rack mount hardware used in the "Big Foot II" project, it followed that I could help the lab by bringing together the proper instruments, rack mounted, in a short rack with a flat work surface and make a self-contained thermal data acquisition system. Part of our responsibilities, as product designers, was to run a thermal profile of any new instrument designed. Completing a well engineered thermal profile on a new instrument was a big job and quite time consuming if done correctly.

The thermal profile is an important development step in the design of new instruments. If some areas get too hot, it could force serious changes in the placement of major assemblies and cause a redesign. To complete a thermal profile required placing as many as 30 thermocouples throughout the new product, turn the power on, and monitor the temperature at each thermocouple. We would do that at high line (128 Volts) and low line (102 Volts). We would do that with fans running and fans disabled. Sometimes we would run test with covers on and covers off. After a couple weeks of testing, we would know where the "hot spots" are in the instrument and how hot it would get.

|

Thermal Data Acquisition System |

In order to make it easier to run these tests, I worked with John Page, our lab manager, and proposed the idea of a thermal test system. It would include a programmable computer controlling the switches to select the appropriate thermocouple, a programmable voltmeter to read the temperature at that thermocouple and the computer would be used to step through the various tests and store the data for later analysis. It would also include a Variac for setting the AC voltage into the unit under test. It included an AC ammeter to measure line current and outlets to power the instrument under test.

John gave me the OK to go ahead. I put together the system. it worked well, was on casters for easy movement from one end of the lab to the other, short enough to fit under the lab bench when not in use, easy to set up and was used to run thermal profiles on many instruments. We used a programmed set of instructions in the HP 9825 to control the tests through the HPIB cable to the other instruments. The thermal profile test system was designed and constructed along with and in addition to my other projects and responsibilities.

A company by the name of Wahl made an infrared hand-held thermal sensor for spot checking temperature. It was shaped like a large pistol and one would point it at the hot spot to get a reading. Hard to use though, when the instrument covers are on, but one still wants to know the temperature of a device. Other thermal test devices were available that would focus on the components of a PC board and take a thermal photo. They were helpful sometimes but quite expensive. For good thermal information, I used the thermal test system most of the time.

Speaking of Spokane Washington, my home town and a fine place to live. In early 1981 my Dad was celebrating his 90th birthday. Donna and I attended this celebration. Lots of pictures taken and lots of family and friends visited Dad at his office to wish him well. Even the Mayor of Spokane came to his office and participated in the festivities. William DeVries Company was the name of his business and even at age 90 he would go to his office every day. It was a service station supply business. He would greet customers, make sales, keep the place clean and enjoy every day at his office. He had inside storage parking and a parking lot to the left of the building. He had three gas pumps to service customers. He was boss and the only employee throughout most of his years there. He lived in his apartment above the business. An easy commute up or down about 30 steps.

Not long after we returned home from Spokane, I spent some time in the darkroom developing and printing many photos taken at Dad's 90th. I put the photos in chronological order and mounted them in an album and shipped it off to Dad. He was delighted to have this photo record of his 90th. He would show it to friends and customers as they came and went from his office. He really enjoyed it viewing it and sharing it with others. Even though I've been a little critical of my Dad, he was a good fellow! He passed away at age 92.

About April of 1981 our division manager, Rod Carlson, knew that Donna and I liked to bicycle. Rod stopped by my desk one day with an advertisement of a Dutch individual that started a company that conducts bicycle tours of Northern Holland. It was called International Bicycle Tours. DeVries is a good Dutch name. We read about it and sent for more information. We got quite excited about the idea and signed up for three weeks of bicycling in Northern Holland. We left for Holland in early September '81. We biked over 400 miles on the two week tour then spent the last week In the "Hotel Smitz" in Utrecht. We visited various Dutch cities by train and just walking the streets of Utrecht, Amsterdam, Rotterdam, Gouda and other fine Dutch cities. Several folks asked me directions to various places because I looked like a typical Dutchman. I had no idea what they were asking because that language is foreign to me. It was a memorable trip and needless to say, I took several hundred pictures. Both black & white and color slides. Later after organizing the slides, during one lunch hour I presented a long-winded slide show about our Holland trip to my friends and co-workers in the HP 5M1 conference room.

|

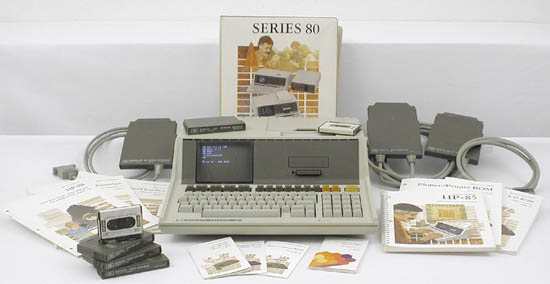

HP-85 "Personal Computer" |

For a Christmas present on December 1981 Donna bought me a Hewlett Packard computer. It was just what I wanted. The HP-85. What a fantastic tool and toy. It came with lots of software, a small screen, a standard "qwerty" keyboard, an integrated printer and a tape recorder/player for programs. I really loved it and used it daily. It took me a while to learn to use it to the fullest. It was programmable so I did a little programming in Basic. The HP text editing program was awful but, fortunately, a little later Tom Ligon wrote a program called "Text 85" that was just wonderful. Not long after that I got an Ink Jet Printer that worked fine with the HP-85. This was my first real computer and I was sure computers couldn't get any better than this. I was so happy!

Then later, I purchased the HP 150 computer along with an "A" size HP plotter. It had a touch screen, a fine large keyboard, a larger sharp display, an internal thermal printer. . . it had everything a person would want. I used a HP 150 at home and another at work. I could bring work home just by having it on the floppy. In those days it had lots of memory, single then double sided disk storage. There is no way personal computers could get better than the HP 150. Boy, was I wrong about that. I can't tell you how many computers I've had since.

Because we were a world class company and selling our products into countries that used the metric system as their measurement system, HP decided to convert everything to millimeters rather than inches. This was a big and expensive change for HP. It involved almost everyone in the company. I was asked to be our labs metric coordinator in addition to my regular product design activities. There were large meetings involving all the lab folks as well as smaller meetings involving model shop machine operators and tool makers. All our lab hardware was converted to mm. All our measuring tools were calibrated in mm. That included micrometers and vernier calipers. The model shop and production shops changed all their tooling for the metric system. In the lab, initially we used dual dimensioning, both inch and millimeter. Later all drawings were in millimeters. Any tapped holes in castings or plastic moldings were mm. A lot of time and money was spent converting from one system or another.

As lab metric coordinator I was to hold classes for the other engineers in our lab discussing and demonstrating the use of metric measuring tools. I'm sure they all knew how to use a metric scale and how to read the little marks on the scale, but it doesn't hurt to review. One day, before class I asked our prettiest and shapely secretaries in the lab if she would help me with a metric measurement demonstration. I explained what I'd like to do and she agreed to help me.

Toward the end of the class I told the 30 male engineers attending that I had a practical measurement demonstration. I had a flip chart with a drawing of a pretty lady on it. I had arrows pointing to the hips, waste and breast. The drawing showed the lady with arms outstretched. About that time, our pretty secretary came in the room and stood by me with arms outstretched. I was getting some offers from my lab coworkers wanting to help me. "No, I don't need help. . . just pay attention as I make these measurements." So, I proceeded to get her hip measurement in centimeters and wrote it on the chart. Then I did the waste measurement in centimeters and wrote it on the chart. Now I was offered even more help. Several guys even stood up and started to come forward. I told them to go back, sit down and pay attention as I made this last measurement. So with my metric tape in hand, I brought one end of the tape toward her breast, and since her arms were outstretched, I measured the length of her arm to the finger tips. Several guys were so disappointed that they tossed their coffee cups at me, called me names and I got a lot of hissing and booing. It was a memorable experience and one I'll never forget. I thanked and think of the dear lady that helped me with this demo. See. . . Metric conversion can be fun!

Throughout later years before my retirement, I got involved in phone screening and inviting various potential mechanical graduate students out to Palo Alto to have an in-plant interview and tour. This was to learn if we thought this candidate would become an interested contributing smart product designer. HP had a system where various engineers would visit some of the best schools and interview graduate students looking for work. Various professors would confide in our interviewers the names of the better students and their GPA. Our HP guy would interview and if he or she passed this initial interview then their name and recommendation would be sent to personnel.

Then personnel would contact one of us in the lab to do a phone screen. If the candidate had potential, we would invite them out. Usually the one doing the phone screen would be the candidate's host for the day. I know I did more than fifty phone screens over a six-month period and invited out several different candidates. The host and five or six engineers spent the day interviewing the invited candidate. This procedure took most of the day. By the end of the day, we'd vote. . . should we make him an offer? In some cases, it was clear. This person was HP material and would make a fine designer. In other cases some voted yes and some voted no. Generally, the section manager had the final say.

One day I called Pete Zivkov on a phone screen. He sounded good to me so we invited him out. Later I checked with our Personnel Department asking when would he be coming out? The nice lady in Personnel said, "Pete Who?" I told her that we wanted to meet with Pete and so we invited him out for the in-plant interview. Oh, she said, "I just tossed his paper work in the trash because I hadn't heard anything about Pete." She searched her trash, found his paperwork invited Pete out, we interviewed him, all of us liked him so we made a job offer and he accepted. We all celebrated that evening at a fine Palo Alto restaurant.

Pete turned out to be a fine HP employee. He contributed to our excellent product designs in many ways. He was a real asset regarding CAD systems too. I'm so happy we didn't let him slip through the cracks.

We hired several new product designers in a short time. The tradition at HP was to have one or two product designers sitting among six to ten circuit designers. The goal was to get good feedback from the circuit designers as instruments evolved. Because I was chosen to mentor four new product designers and because we were all using CAD and we had one plotter to share and to send drawing to be plotted, we created a friendly arrangement of desks, work benches and plotter. We called this arrangement "Product Design Central." We were positioned near our respective circuit designers but we were within arm's reach of each other so we could discuss problems and solutions.

Our group consisted of Doug Halbert, Jim Bertsch, Theresa Loney, Julie McDonald and Pete Zivkov. Ray Shannon was our lab manager. I always liked the open door policy he had for mentors. Any of these new folks could do dumb stuff or ask silly questions but those details never got back to management to go into their evaluations or personnel records. When evaluation time came, I was frequently asked by the project leaders, "How is Theresa doing or how is Pete doing?" I would tell them, "you must find out for yourself, I can't tell you." This approach was fair and reasonable. It gave the new employee total freedom to seek information and It forced the project leader to get to know the new kid on the block much better. I'm proud of all the new engineers that I've worked with. They have been successful in many ways. I won't take all the credit but maybe I helped? Being a mentor was a good experience for me. I'm sure I learned more from the new employee than they did from me.

As a product designer this manual was most helpful. It contained several sections describing preferred engineering parameters for sheet metal, castings, plastic moldings etc. In the sheet metal section it listed preferred hold sizes, fold radius, holes near folds, holes near edges, etc. All these little aids helped all MEs from making fewer design errors, fewer prototypes required in the development cycle and shorter period to instrument release to production.

Many of our new microwave instruments required higher frequencies to function properly. This required semi-rigid coax rather than flex coax to interconnect modules. There was no section in our engineering manual for semi-rigid coax fabrication. Yet making semi-rigid cables is just as complex as sheet metal design and fabrication. So, to make a long story short, and with the aid of John Borgsteadt we added two new sections to the manual. Semi-rigid Coax design and fabrication and the other section was devoted to Extrusion design guidelines.

It's amazing to me how much I've learned about myself as I put this information together. While looking through old evaluations I was surprised to recall that I was quite stubborn, didn't really like too much constructive criticism, was more of a product designer loner than a "team" guy and I wanted to work efficiently and effectively. These characteristics were noted and commented on by several different project leaders over many years.

I listed below various projects and products that I worked on. In many of these activities I was involved from start to finish and some of them I was providing some consulting or preliminary design help to various co-workers.

As I became more experienced as a product designer and really was familiar with the design routine, I could get lots done. I loved to multi-task. As I plotted drawings from the CAD system, I could be writing a note or memo or checking on parts. As parts were being made in the model shop for one project, I'd be working on drawings or design for a different project. I could run temperature tests during project meetings and have the results after the meeting was over. Doing two or three things at a time worked well for me and resulted in lots of completed projects in a short period of time. From a list of completed projects in this ten year period, I count 58 projects completed. That's 5.8 projects per year.

I'm sure the reader is wondering how Bob does it. How can he recall all those details? Well, I never throw anything away so I have old evaluations and raise slips from HP. I have a computer file I call "What/when" that is a listing of significant happenings over the past 100 years. I have an Agilent catalog for reference, three notebooks of black & white and color negatives, some are of HP projects that I helped design and there are other references too. In putting these memories together, I look in one book then another to get most of the dates and details correct.

Two things make me quite proud during my thirty-four year HP career as a product designer.

1) I was always on time or ahead of the schedules and never in the critical path on any of my assignments. That included over 130 different projects.

2) I missed only one day of work in those thirty-four years due to the 24 hr flu.

As I look back over these many pages, it seems that I'm focusing on my self too much That isn't my intent to be tooting my own horn all the time. My objective was to communicate, to the reader, the many products that I focused on during my 34 years at HP. I also wanted to include some folks that really made a difference in our lives. This was also a summary of some of the paths we took and "Y's" in the road of life. I sometimes wonder what would be the outcome if we took the other path at the "Y" junction? We'll never know. I certainly have no complaints and consider myself very lucky to have met and married Donna, learned about and was hired by HP, worked in their fine lab doing what I love to do, and working with so many wonderful and knowledgeable people. What could be better than that?

Palo Alto, CA

July 2011

Bob DeVries

_____________________________________________________________

120A Oscilloscope Cabinet and Rack Mount Version Redesign to 120B

120A Oscilloscope Cabinet and Rack Mount Version Redesign to 120BX & 120BRX

120H Oscilloscope, 3" Version for Hughes (a redesigned 120BRX)

120N Oscilloscope, 14" Deep for the Navy (a redesigned 120BRX)

120 X/Y Oscilloscope (Special. . . another redesigned 120BRX)

166A Dummy Plug-in for the 160 Oscilloscope

166B Time Mark Plug-in for the 160 Oscilloscope

166C Display Scanner Plug-in for the 160 Oscilloscope

166D Sweep Delay Plug-in for the 160 Oscilloscope

170A High Frequency Scope Engineering Support

185A Sampling Scope Engineering Support

130C Oscilloscope, Single Beam, Low Frequency and Sensitive Oscilloscope

132A Oscilloscope, Dual Beam, Low Frequency and Sensitive Oscilloscope

_____________________________________________________________

3513A 7 Channel, 1.5MHz Record Mainframe Design

3514A 7 Channel, 1.5MHz Reproduce Mainframe Design

3534A Direct Record Plug-in Design

3535A FM Record Plug-in Design

3535A Opt 01 Plug-in Design

3537A Plug-in Design

3538A FM Plug-in Design

3538A Opt 01 FM Plug-in Design (Flutter Compensation)

3540A Plug-in Design

3541A FM Record Plug-in Design

3543A Plug-in Design

3544A FM Reproduce Plug-in Design

3950A 14 Channel Preamp Housing

11539 Reproduce Track Selector

11560 Dummy Plug In

Amplifier Extractor and Extender

3535A FM Record Oscillator Drift Investigation

2 MHz System Labeling Plan

7 Meter Reproduce Mainframe (Special)

Tape Speed Tachometer (Special)

Low Speed Equalizer (Special)

3604A Voice-Channel for tape systems

3605A Frequency Source for Calibration

3960A Portable Instrumentation Recorder

32 Channel Preamp Housing investigation

Transistor & Diode Curve Tracer (Special ET)

Power Line Monitor (Special ET)

Isolation Power Supply (Special ET)

_____________________________________________________________

8640A & B Design Instrument (Except Dial and Oscillator)

11687A 50 to 75 Ohm Adapter

11690A Frequency Doubler

Four Voltage Power Module

86701A Preliminary Design

86710A Preliminary Design

85050A Network Analyzer Preliminary Design

85052A Network Analyzer Preliminary Design

85055A Network Analyzer Preliminary Design

8640A/54A Attenuator Tester (Electronic Tool)

Rotary Pulse Generator (RPG) Redesign for Cost Reduction

8660A Fan and Heat Sink Changes

11661 Redesign Module for Easier Access

86720A Design

86720B Preliminary Design

86721B Preliminary Design

86710B Preliminary Design

86701B Preliminary Design

8662A Synthesized Generator Design

8663A Synthesized Generator Preliminary Design

8903A Audio Analyzer Design

_____________________________________________________________

11715A FM/AM Frequency Source Design

8955A System Design (Big Foot I)

8956A Preliminary Design (Big Foot II)

8901A Design Modifications

8901B Preliminary Design

1722A Remote Sensor for 8901B Preliminary Design

Temperature Data Acquisition System Design

11721A Frequency Doubler Design

Metric Coordinator for the SPD lab

Geometric Dimensioning & Tolerancing (GD&T) Coordinator

Interview for new product designers,

Mentor Pete, Theresa, Julie, Jim Bertsch and seed students

Vector Demodulator Design (ET)

Variable Delay Line (ET)

Evaluation of multi-conductor flat cable and connectors

Evaluation of multi-layer PC Boards

8970B Noise Figure Meter (Assumed responsibility and released to prod)

CAD Activities: Mint, Draw, Draft, Titus, Piglet, Anvil-4000, EasyDraft II ME-10

E-mail Activity: EIES & Confer

Investigation of Mint to replace HP Draft Cad System

Investigation of HPs ME-10 to replace Mint Cad System

The conversion of Mint drawings to ME-10,

Investigation of Mint to replace Draw Cad System

Parsyn Breadboard Design

Parsyn DAC preliminary design support

8770A AWS Preliminary Design

86970A DATA SOURCE Preliminary Design

86971A ACS Preliminary Design

86972A IF Agile Preliminary Design

8971B Noise Test Set (ET)

8353/4A Mid '86 Preliminary Design Considerations. . . scrapped to focus on Si'

347B mm Wave Noise Source Design Assistance

8970A Production Modification support

437A Power Meter Preliminary Design

8675A Late '86, Preliminary Design Considerations for Al Barber on the "Si'" synthesizer

MMS Modified Tracking Generator Design Considerations

MMS Repackage 8673 Output Design Considerations

Peltier Cooler (ET) Preliminary Design for Ron Larson

Hi Speed Modulator using Peltier cooler to maintain modulator temperature

8487A Design Assistance to Pete Szente

ET-25022 Programmable Power Supply Design Assistance

08770-KOI Frequency Divider and Signal Source design assistance

A Section 614 additions of the Corporate Design and Manufacturing Manual on Semi-Rigid coax cable design and a section on extrusion design.

8370 Family of Synthesizers including Si' and Simore

MMS equivalent of 8370 family of Synthesizers

VXI equivalent of 8370 family of Synthesizers

83710A & 11A (Si') Product Design

83711A (Si'more) Product Design

83712A Product Design

83713A Product Design

83730A & 31A (SiMore) Product Design

83732A Product Design MMS Equivalent Mockup/Drawing of 83711A Prelim Design

VXI (D-Size) Equivalent Mockup/Drawing of 83711A Prelim Design

MMS 70100A Power Meter EMI and Grounding problem solved

Semi-Rigid Coax section of Mechanical Engineering & Manufacturing Manual

Extrusion section of Mechanical Engineering & Manufacturing Manual

MCG Platform Task Force

MCG Sbeetmetal and Standard Instrument Task Force etc.