HP Memories

Editor Note:Life Sets our Schedules We've been working with Bob for several years now, to capture his fascinating life and times, from his Purdue engineering student days, through retirement. We used content from his oral history, converting it into a first-person narrative, and other material that he supplied from his pictures and files. We came to a pretty complete "final" draft, which still needed a little of his attention, and a few peripheral questions answered. That was more than a year ago. But any of you who knew Bob, knew that his days were full of volunteer work, so he continued to defer his attention in order to do what he loved. He was volunteering for some new election issue, working on his beloved Tech Museum tasks, and just now, a safari trip to Africa. That is where Life took over his schedule, and left all of us stunned by his sudden demise. With the permission of Bob's children, we have finished the contents of Bob's interesting and challenging life story, leaving a few minor holes, and published it herewith. But it still reveals a truly amazing man in his quest for technical excellence and a humanity in spirit. His HP story shows again just what a rewarding work culture we had at HP, propelling all that growth in the second half of the 20th Century. Along with his wife Marion, they fulfilled the Los Altos community vision. Bob's Memorial Service in San Jose on May 2nd, was truly remarkable, with extensive displays of his times and service, along with remembrance talks of many friends. It is all described at the end of this HP Memoir. |

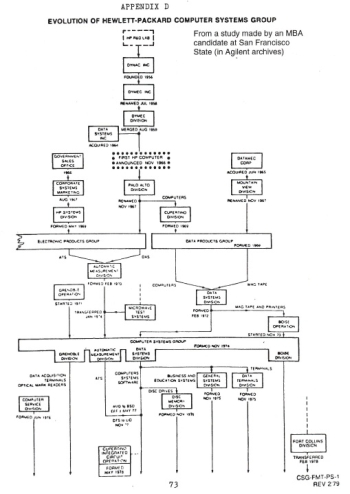

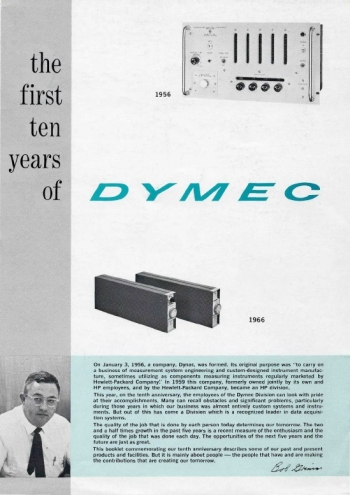

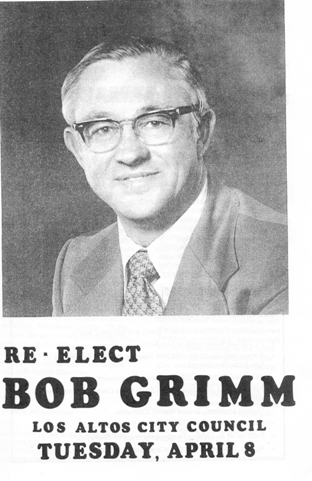

ForewordMr. HP Management Pioneer -- Mr. Civic Volunteer Hero -- Bob Grimm The life story of Bob Grimm is not well known, even among those of us who were at HP during the same decades. We, of course, knew that Bob's name was connected with the new "System Division," in 1956, which was called Dymec. But his HP career really started 5 years before that, in the early-1950s, when he was one of only 20 engineers, working in the original Redwood building. I did not know that he was getting ready for his long HP career by designing the modulator for the 618B signal generator. Or that he was in the middle of design of those somewhat obscure TV and FM 335-series broadcast monitors--I somehow thought those were Al Bagley's domain. Nor did I realize that Bob was one of the designers on the legendary HP 150A, the first 10 MHz oscilloscope introduced by HP. The introduction story of the 150A, at the 1956 IRE Show in New York City, in the middle of their worst snow storm in 20 years, alone, is a fun reason to read on. Every one of our previous HP memoirs has some kind of charming story in the life of the author. In Bob's case, I was fascinated by his life at Purdue University. First of all, his faculty advisor was Professor John Cage. John Cage had previously worked for General Electric, and back in about 1938, turned out to be the boss of a brand new Stanford Electrical Engineer, David Packard. Cage then moved to a Purdue professorship, a few years before Packard hired him into the HP Labs, to manage the low frequency section. But, in a prediction of his later career, Bob ended up at Purdue in a "custom electronics shop," which was charged to design and build ANY electronics assembly that was needed by the school. A sort of industrial custom model shop. Little did he know that, in his later Dymec days, he would be meeting similar customer needs for custom measurement systems, probably the true joy of his life. Bob relates how Bill and Dave decided that there was a profitable demand in customer needs for assembled measurement systems. Many aerospace and other industrial companies bought HP instruments and had system engineers who integrated them into complete programmable systems. But that wasn't easy because so many of HP instruments of the time WERE NOT programmable. Stimulus instruments like signal generators used hand cranks to tune frequency. Measurement instruments had NO DATA OUTPUTS. So Dymec developed engineering expertise to modify standard HP instruments. Believe it or not, they invented motor driven servo systems to rotate those hand cranks. They even built "knob twisters" which could rotate selector knobs on a standard front panel. That was the state of measurement automation before the advent of the HP-Interface bus. It was rudimentary, but it worked, and customers were delighted with having HP do that system integration, rather than themselves. But looking back, there is no doubt in my mind, that one of Bob's early Dymec projects had an massive effect on the Hewlett-Packard of the 1980s onward. And that was HP's first mini-computer, the HP 2116A. Created by the creative team under Kay Magelby, it was introduced in 1966. It became the ancestor of HP's enormous successes in the computer industry through 2014. The HP 9100A desktop calculator, introduced several years later, and intended for individual engineers, then proved that HP creativity could be applied to computation at the workbench. After some years, Bob left Dymec, as they divided their product line into data acquisition and automatic measurement systems. He was one of the principle managers in the new Automatic Measurement Division, first downstairs in Bldg 11, and then Sunnyvale. And incidentally, Bob was my boss when I moved to AMD in 1972. So I was able to watch his excellent management skills in a business market that was clearly different than selling instruments one by one. This was high-level selling, because the sign-off for some of those systems were $100--200K+, meaning often it was a vice-president approval. After a few more years of system management, Bob transferred to a corporate marketing job, reporting to Noel Eldred. No one would ever turn down an assignment with Eldred as your boss, because he was THE preeminent marketing executive of that high tech age. This led to more opportunity in HP Labs, except that in this case, his boss was the formidable IQ=180, Barney Oliver. Wouldn't THAT be intimidating? It would be for me, and I had some experience, since Barney was my interviewer, when I walked in the front door of HP at 395 Page Mill, and applied for work in 1957. Out of that initial work for Barney, came the job as "provisional" manager of a huge project to design and install an integrated circuit engineering and manufacturing facility within HP Labs. Bill and Dave and Barney merely proclaimed that it was to be the best state-of-the-art process center that we could build. Bob gathered a team of expert engineers and scientists and started to build in Santa Clara. But along came a vacant Fairchild building over on Deer Creek in the hills behind HP. With that purchase, Bob and his team did indeed create the capabilities that befitted the other creative talents of HP's Central Research Lab. Bob ended up as Director of the IC lab for about 8 years, during which time they supported some of the most advanced instrumentation and computer technology that was happening on this earth. After Barney's retirement, and John Doyle's reign as HP Labs V.P., Bob took over as Director of the HP Technology Center, one portion of the Labs. After a few years, he became Director, HP Manufacturing Technology Center, a forward-looking group of scientists and engineers, who took as their vision, to change the way HP manufactured their products. Their eyes were on future manufacturing processes. How to DESIGN for manufacturability. How to automate assemblies, how to use robotic technologies, how to produce state-of-the-art printed circuit boards with automated surface mount elements. The production efficiency leverage of these concepts would sweep over the company for years. Bob looks back on a remarkable career of innovation, creativity, management success, and leadership in cheerleading the best of his people. But all during those HP decades, Bob was spending some good percentage of his time outside HP, in a continuing commitment to industrial volunteering. Almost from his first years at HP, he followed the good lead of Bill and Dave, in offering his talents to community service. The list of different organizations range from the United Way, to Mayor of Los Altos, to becoming one of the Founders of the science museum called the San Jose Tech Museum (The Tech). The actual list of civic organizations goes past 12. Imagine that, considering that he was holding down some tough leadership jobs at HP, with major demands on his time and energy. But he did both, for most of his years. There is no doubt in my mind that he is the HP record-holder for his years of community volunteerism. All along that way, he was accompanied by his wife, Marion, who was matching him on continuing civic service. His memoir, herewith, shows that he had a lot of fun doing them. John Minck |

![]() Click

here to download Bob's memories in PDF format - The 56 page

document is a 7.65 Mb PDF file.

Click

here to download Bob's memories in PDF format - The 56 page

document is a 7.65 Mb PDF file.

I was born December 16, 1926, in Macon, Missouri. Macon is in the north east corner of Missouri, sixty miles west of Hannibal, the home of Mark Twain. Macon had a population of 4,000 people that year, almost 90 years ago, and it still does.

My dad was a Lutheran minister in Macon. We lived in the parsonage, right next to the church, so I grew up as a preacher's kid in a small town, with the eyes of that world on me. That was a very interesting life because I didn't know anything different.

I had one brother and one sister. Both of them were younger. My brother was a judge in Missouri on the Court of Appeals, and died in 2012. My sister's name was Donna. She lived in Portland, Oregon. She was a CPA. She and her husband, Stan Gieger, had a company that did biological research in the environmental field. They measured water pollution and designed remediation for it. She died in 2006.

Even coming from a bible-based household, I guess I was always interested in electrical things when I was growing up. I liked to do things, to a large extent by myself, and luckily, my dad was supportive of my projects. We had what was once a small chicken house next to our detached garage. It was about 10 x 10 feet. We got rid of the chickens at some point, and my dad let me have it for a shop. I spent a lot of my time out there. I was always interested in electrical stuff. I built my own darkroom, built my own enlarger. It was a projector I converted to an enlarger. I built a table saw. I had a good time working by myself.

It was a happy time. And depression time, but I don't think we ever thought about it. Money was tight, but we had big gardens. During World War II, we had a victory garden like a lot of people did, in addition to our regular garden. My mother baked every week, and she baked almost all of the breads and pastries and coffee cakes and other things that we had. She canned during the summer. She canned tomatoes and corn and green beans and pickles and everything, and that was used up in the winter. We had a lot of fresh fruit and vegetables during the summer. A lot of the congregation were farmers, and they would bring in food and other commodities. We weren't suffering, I mean, we didn't have much money, but neither did other people.

I was always wiring things and doing fun projects. I had a paper route when I was probably in about eighth grade. A guy named Jimmy Blankenship, about a year older than I, lived at one of the places on my route where I'd periodically stop to fold my papers. He was very smart and he was into radios. He was actually building radios and we got to talking. I decided that I wanted to build radios too, so he showed me how. We built superheterodynes. Then I collected old radios. I didn't have enough money to buy parts, but I got all the parts I needed by taking old radios apart. There were a lot of old radios around.

The first real job I had, after my paper routes, was working in the Kroger grocery store at thirty cents an hour, the going rate at that time. I would work after school and on Saturdays. During the summer, I would work full time, and full time then was sixty hours a week. I got paid $18 a week, less social security, which was about twenty five cents. Those were long days compared to what people think of now. The store opened at eight and closed at six and that's what you got paid for; but you had to have the store ready & stocked, before it opened, and you had to clean it up after it closed.

Macon was a farming community, so Saturday was the busiest commercial day in town, because that was when all the farmers would come into town. Then we'd open at eight in the morning and stay open until ten at night. These were the days when things like flour and salt and beans were bought in large 40 to 50# sacks. I can still remember these big burly farmers, they were strong enough to lift an ox, coming in. Of course, they'd park two blocks from the store and I had to carry all their supplies from the store to their cars.

There was a man who ran a florist shop, who had been a radio hobbyist. The nice thing about him was that he had saved old radio magazines. All the new magazines had circuits using tube types that I didn't have, because all my parts came out of old radios. So he gave me these ten-year-old magazines, and that allowed me to built stuff from those circuits. Then Jimmy and I started building transmitters so we could communicate back and forth.

Of course, we were transmitting without a license. We had a good time and my folks encouraged me. The only guy who really understood electricity in the whole town was the radio repairman. I was always pestering him, and asking him how to fix things when I got stuck. One Christmas my folks asked him what to get me for my gifts. He recommended a radio physics reference book which was about three inches thick. I read that thing from cover to cover. It had all kinds of oscillators, Colpitts oscillators and Hartley oscillators and a lot of other "modern" circuitry.

They called it a radio physics course, but it was really circuits for electronics. It was a lot of fun. I went on doing things like that through high school, playing with equipment and building more complicated things as time went on. I was in high school during World War II, and it was pretty obvious that as soon as I graduated from high school in 1945, I would have to go into the military. At that time, if you passed an examination called the Eddy Test, you could go into electronic technical training in the Navy. That sounded like a better deal than going into the Army, so I took the test and I passed it. I didn't want to go through the ceremony of graduating from high school anyhow, so I talked my folks into letting me leave early, and went into the Navy, in May of 1945. My high school degree was mailed to me.

Captain Eddy was the name of the man who developed a training course for electronics service men. It was a crash course. The way it worked was, you went through boot camp, a short basic training of only about two months. At Great Lakes Naval Station, near Chicago, they had pre-radio, which was just fundamentals of electricity. It was a one month course held at former Hugh Manley High School in Chicago. Next, I went to Gulf Port, Mississippi for primary. That was for another three months. Then I went to Corpus Christi for seven months of what they called secondary. I came out with an aviation electronics technician rating.

The whole course lasted maybe about a year. The nice thing was that while I was finishing up, they finished up the war. After I graduated, they didn't really need more people so they put me to work at a small training airfield near Corpus Christi. All I had to do was gas planes, crank them to get them started and wait for my discharge. It was a pretty nice way to spend the war and out of that I got the G.I. Bill. They gave you a year plus the time you'd been in the service. I'd been in the service for a total of sixteen months, plus twelve, made a little over three years of college that I was entitled to. That really helped because my folks didn't have enough money to pay for my college.

I later found out that my HP friend Cort Van Rensselaer also took the Eddy Course, and his experience was very similar experience to mine. He took the course and then they didn't know what to do with him, except that he got his ROTC commission, and they sent him to Hawaii to wait out his time to muster out.

Altogether, I was in the Navy for 16 months, from May, 1945 to August, 1946. As I left the Navy, I could have gotten into the Fall semester of '46, except all the schools I tried, were full. All the WWII G.I.s were coming back, and you just couldn't get in. It was obviously going to be a long wait. Then my dad suggested Valparaiso University, which was run by the Lutheran Church. Valparaiso is in northern Indiana not too far from Chicago.

When I started college, the father of a good friend of mine, Irving Zelade, who was in charge of the Missouri State Highway Department in Macon, asked if I would be interested in working as a calculator or computing assistant there. Of course, calculators and computers weren't invented yet, so we used adding machines and mechanical "comptometers" for our engineering computations. During the Fall of 1946, I did drafting for them, and also calculations on "cut and fill" highway cross sections. They used those calculations for layouts of proposed highways. It was good experience, and heavy on math.

There was no problem of getting into Valparaiso, but they didn't have a four year engineering degree. However, if you went there for two years, they had an arrangement, whereby you could transfer to Purdue. I couldn't have gotten into Purdue directly because of the waiting list and the priority of Indiana people. Going to Valparaiso seemed like a logical thing to do, so I went for two years. I started in February of 1947 and just took the first two years of general engineering courses. They had moved some dorms in from an Army base, and these were all filled with ex-G.I.s. I went there for two years, and then I entered Purdue in my junior year. I got some credit for being in the military, which was my technician rating. You didn't have to take physical education, and there were a couple of other things they gave us credit for. So I entered in as a junior plus, and I actually finished up in a year and a half with my BSEE degree, in June, 1950.

My college social life was pretty uneventful. I always got pretty good grades, and after about a year at Purdue, somebody said, "Wouldn't you like to join this honorary society?" I can't remember which one it was. It was either Tau Beta Phi or Eta Kappa Nu. I was anti fraternity. I mean, most of the G.I.s didn't want to have anything to do with that stuff. So I said, "No, too much bother." They came back later and explained what it was, and I went ahead with it then. I joined all three; Eta Kappa Nu is the electrical engineering society, Tau Beta Phi is engineering in general, and Sigma Xi is general science.

After my BSEE, I just stayed right on, to get a Master's Degree. I didn't take any vacation that summer and just went straight through. By that time, I was out of money. My G.I. Bill had run out and my folks couldn't help, so I had to earn everything. I usually had several jobs at a time. I got a job as head of a dorm, which gave me free rent. For a while I worked in the kitchen of a sorority, which gave me meals. I also made money as a bellhop in the student center where they had a hotel.

When I got into graduate school, I got a job in a lab called Campus Electronics Service. It was a service lab in the E.E. School that made electronic equipment for any other part of the university that wanted something made. The head of this service was a guy named Al Todd, a very bright and creative engineer, and there were half a dozen students who worked in there, part time.

The nice thing about that job was the tremendous variety of projects that would come up. For instance, the Agriculture School wanted to determine the effect of moisture in the ground on the growth of tomatoes. Al Todd planned most of the basic ideas for the design approach to take, but then all the work of designing the circuits was done by us students. On that one, he obviously wanted a resistance measurement, but because of polarization we had to make an AC ohm meter.

Then, I remember the psychology department wanted something that ended up being essentially a lie detector. They wanted to measure skin resistance. An interesting project, for example, you think of a number between one and ten and I'll count. I'd put the electrodes on your skin, I would count out loud from one to ten, and I could tell immediately when I'd pass your number. There'd be a variation in resistance from your perspiration. The projects we got were interesting and varied and it was a wonderful experience.

I had to have a thesis for my Masters degree. I was able to choose a project that needed to be built and do it as my Masters thesis. It was an interesting project, I ended up teaming up with a master's degree student in the Mechanical Engineering Department. He was trying to measure the stress strain characteristics of metal as it was being punched, only done dynamically. It's different if you do it dynamically rather than very slowly because the metal breaks part way through the punch cycle.

My job was to design all of the electronics necessary to plot out, on an oscilloscope, the stress strain curve. We then could take Polaroid pictures of the stress/strain as the one inch diameter slug was being punched out of metal. Then we would vary the clearance between the punch and the die, to determine what was the most effective clearance and the most effective punch speed. To do that we used a differential transformer to determine the vertical position of the punch as it was going through. We put a strain gauge on the punch itself, that could tell the compression in the punch die, and therefore measure the amount of force applied. It had to be fairly fast, so we decided we needed to use a carrier frequency. We used ten kilohertz as the carrier frequency on both the strain gauge and the differential transformer. We used a phase detector on the output. We had a way of triggering the camera when we operated it so we got beautiful stress strain curves. He got a thesis out of analyzing all of the punch data, and I got a thesis out of describing the circuits and how the experiment was set up.

It was a nice educational project. I learned a lot of really practical stuff from all of these projects. Working there was a lot more interesting than the subjects I was studying. Transmission line theory and fields and mechanisms didn't really have the touch of reality. Here you were working on real things that real people were going to use. It was at that time that I decided I wanted to work in a company that made real products and not just in radio or electronics for its own sake.

The project's measurement orientation was important too, because it supplemented my regular course work. I think it added realism to what I was studying, and no doubt influenced my later decisions to pick Hewlett-Packard for the measurements technology. Some of the work came easy because we had to build everything in this little shop room. You punched all your chassis with Greenlee punches, and folded them on a sheet metal brake. You had to make the front panel, and the whole works, and then design it like a finished product. Also, you had to write the manual for the people who were going to use it. Altogether, it was excellent training, and I was so pleased that I had landed that work.

When I graduated in August of '51, it was a seller's market, Korean War military mobilization. If you could say EE, you could get a job. There were more campus interviews than you could handle. I interviewed with many companies and received nine firm offers.

I had excellent grades. Being in the honor societies was a very, very saleable item on your resume at that time. I went back to some of the companies on the East Coast. I had an offer from Bell Labs and Sperry and some others on the East Coast. I had decided that I definitely did not want to live in the Midwest. Other than for interviews, I'd never been to the East Coast and I had never been to the West Coast. My time in the Navy had been straight up and down the country between Illinois and Texas, but I knew it had to be better on the coasts than it was in the Midwest.

At that time, my major professor was John Cage. One day he called me, and this was early in the interviewing process, and he said, "We've got this company called Emerson from Saint Louis. Would you like to interview them?" I said, "No, because they're from Saint Louis, and I don't want to work in the Midwest." He said, "Nobody has signed up to talk to them." And he was a little bit embarrassed about this. I said, "I'll be glad to go and talk with them, but I'm not going to accept a job with them."

Let me put this in perspective. When Packard graduated from Stanford, he got a job with General Electric, back in Schenectady, and the boss he went to work for was John Cage. John was Dave's first boss. I guess maybe his only boss, because I think he was there only about a year. Then later on, John ended up being a professor at Purdue and my professor.

He was my major professor of electrical engineering for my thesis. So John had known both Bill Hewlett and Dave Packard, and he had kept in touch with them. He met them at IRE shows and other events, and he had repeatedly asked them if they would hire somebody from Purdue. Of course, HP at that time only had about three hundred people and they were not recruiting nationwide. At the IRE show in New York he again hit them up; and they said, "Why don't you pick somebody, and have him contact us and we'll see what we think about it."

So John Cage, remembering that I didn't want to be in the Midwest, said, "You know, there's this little company out there on the West Coast that you might be interested in." We had an HP oscillator or voltmeter in the lab at that time, and that's about all I knew about the company. The company was in the right place, so I wrote a two page letter to Bill Hewlett. I outlined how I'd gotten into the Navy electronics course, and then I told them about what I'd taken in college. I described several of the projects I'd built with the Campus Electronics Service.

Interestingly, there was never a phone call between us, and they never invited me out to interview. But I got this letter back saying, "We would like to offer you a definite position as engineer in our laboratory." They didn't offer to pay my way out or anything. But it had a nice appeal to it, so I wrote back and accepted.

Click HERE to read Hewlett's job offer and my acceptance

While in graduate school, I had really splurged. I'd never had a car in my life, and at that time I had a little bit of spare money. So I spent $100 the beginning of my last year and bought a 1937 Olds. With a case of oil in the trunk, you could keep it going, and I had a great time with it that last year, around Purdue. When I graduated, I sold it for $100 and I used that money to buy a plane ticket out to Palo Alto. Talk about naive, I got off the plane, and got on a bus at the San Francisco Airport to go down to Palo Alto. I didn't even know where it was. So I got on the bus and I was standing up. There were plenty of seats and the bus driver finally said, "You might as well sit down. It's going to be a little drive." When I got to HP, I had to ask for an advance on my salary. They gave me an advance so I could pay some rent and get going.

I started at HP in August of 1951. My Purdue professor, John Cage, didn't come to HP for another 5 years or so. Those were interesting times for a green new graduate. As I recall, my salary was $300, plus bonus, which was running around thirty three percent at that time. It totaled about $400 a month.

I first rented a place at 2183 Bryant in Palo Alto, mainly because it was within walking distance over to the plant. It was only about six blocks, and a very nice place. Two old ladies had this beautiful home--it's still there-- and they'd converted a two car garage into an apartment they rented out. It had a separate entrance, so it was just great. I was there a couple of years, until probably early in 1953. After that I rented a place for a short time in Menlo Park, and then I rented a place up in Skylonda. That was up on Skyline Road, where it intersects with La Honda Rd, on its route over to the ocean. It was a great place, with a real log cabin with mortar in between the logs. But, a little cool in the winter. It had a gas floor furnace, but the main source of heat was the big fireplace.

I first met Marion in 1952, at the Heidelberg beer garden in Palo Alto, when she was on a date with another engineer from HP. In those years, the Heidelberg was a common meeting place for HP employees after work. We next had a double-date, with me first taking one of Marion's housemates. Then we started dating. We were married on July 9, 1953.

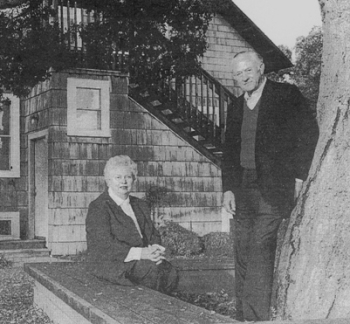

|

The beginning of a very long life collaboration. My father came out to perform the ceremony. |

Marion and I were married at the Trinity Lutheran Church in Palo Alto, on July 9, 1953. My father, who was a minister, flew out to marry us. After the marriage, we lived at Skylonda, for a little less than a year. She was working as a school psychologist for the San Mateo County Schools. She commuted northward to San Mateo, and I came down to Palo Alto. The living was good, but the commute was over hard roads. There are now people that commute much farther than that. They come from Livermore and Modesto and Santa Cruz, all to work in the Bay Area. Those are long commutes. During the entire 35 years I worked at HP, I don't think I ever had more than a 20 minute commute to work.

In 1954, we bought a house in Menlo Park, on American Way. It was a small two bedroom house, but it was a lot closer to work, and it was warm in winter. You can imagine, coming home at the end of the day, up to Skylonda, in winter, and the place was totally closed. It was mainly heated by a fireplace. It was nice to have a place down below. Then, our situation changed, because we were taking two of Marion's sister's two boys, who came out to California to live with us. They were one-and-a-half and three years old, and we'd only been married about a year-and-a-half.

So we moved to a bigger house in Mountain View. We were young and thought we could do anything. Especially since we were handed an instant family, it was hard work. The house was pretty rundown. We painted it and fixed it up, and it was pretty nice. Soon we started having kids of our own, so we ended up with five kids. Then we looked for an even bigger place and ended up here on Parma Way, in Los Altos.

We moved to Los Altos, even though Marion's dream was to have a place up in the hills, where she could look out, and have a terrific view of the whole Bay. But we realistically figured that with five kids, you'd be a bus driver most of the time. So, we found this place, and it was very, very fortunate to find it. It was one acre, off the street, so our five kids had their own creek to crawl in and get poison oak. And we still have a beautiful view out here, maybe not for distance, but it's still beautiful. It was a great place to raise kids, with essentially its own park. Marion was busy with five kids, but still got involved with the town, and both of us were committed to working with community activities.

|

Redwood building, circa 1948. Our engineering group of about 15 people was in one half of this WWII building. |

My first job assignment was to work for six months out in test. Ray Demere was running the test department, and the idea was to get the new man familiar with all the different HP products. I started on oscillators and voltmeters. I'd work for a week on one product and then they'd shift me to another; pulse generators, signal generators and so on. It wasn't air conditioned and I can remember in the summer, we had all these heat test racks, generating heat right behind us. It was an interesting time for me, given my background on electronics. You surely became aware of what designs worked and which had reliability flaws.

While I was in the test department I had a few special projects. I remember, they were interested in depositing resistors on glass plates. They wanted to know the relative frequency characteristics of different configurations. I got about ten different kinds from wire wounds to regular carbon resistors, compared to these glass ones they furnished. So I measured the impedance characteristics versus frequency on all of them. I don't know if anybody ever used the information, but it was something the lab wanted.

I also worked in the stock room and some other areas for a while, and then I went into the lab. At that time, the lab was in one half of the middle room of the Redwood Building, the El Camino side of it, about 2500 square feet. There were maybe 20 of us engineers there. The whole company at that time had about 300 employees. Thirty five years later, when I retired, there were 90,000. So you know it was a very high growth period, and extremely well managed operation. When I think about it now, it was amazing that the company had grown well with such a small engineering group.

I must admit that at that time of my life, I had a wrong opinion of corporations. It was my feeling that corporations tended to do whatever it takes to win. And that they weren't, necessarily, very ethical. And that is still true for a lot of companies, but HP was so squeaky clean. They were cleaner than a lot of the other activities going on in the name of politics, or religion, and other economic activities. Bill & Dave were extremely ethical, and very respectful of individuals. It was very enlightening, and very gratifying to be part of it. Naturally, that brought out the best in their employees, too. I think their values also extended to our local communities, and because they contributed to the community, they brought out the best in those civic values.

They emphasized community participation among other things. So, later on, when I ran for the Los Altos City Council, they encouraged that. They encouraged people to be on School Boards, and otherwise be involved in civic activities, things like United Way. You still had to get your HP job done, but they really encouraged participation, outside of work. Further, they themselves volunteered for Boards and civic positions.

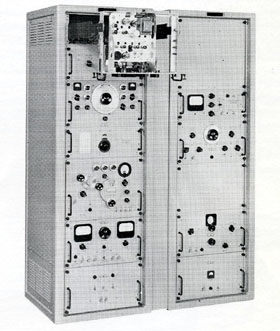

Brunton Bauer was the chief engineer in charge of the lab. I was assigned to work with Bill Myers, who was working on the 618B signal generator. He took the RF section, which was good because I didn't know anything about microwave, and he gave me the modulator section. That was OK, because I didn't know anything about pulse circuitry either, but it was at least low frequency. That was a good experience. Bill was a good guy to work for.

|

HP 618B microwave generator. This was developed under US Navy contract, and once when we went off to prepare for an HP beer bust, Packard came along and "reminded" us about the contract urgency. |

The work environment was pretty casual, although we worked hard. We did have time goals for finishing the designs, since the 618B was working to a US Navy contract. We used to have pretty good HP picnics at Adobe Creek, and the night before some of us would go out and help get things ready for the picnic. These evenings of course, turned into something like a beer bust. There we were, having a great time at Adobe Creek, late Friday evening on our own time. And here came Packard, and he was pretty irate. The very idea that anybody on a contract project, with such high priority, would be spending any time on anything except that project infuriated him.

There was the time I was having great difficulty with some circuits I was working on, and I talked Al Bagley into coming back to the lab to help me out. We went back that very night. It was very interesting working for Bill and Dave those days. They could be pretty outspoken about their priorities. I remember Packard arrived out there at the picnic grounds, and the first guy he saw was Gene Stiles. Gene gave him a happy greeting and got chewed out in return. Within one month, Gene was a salesman for Crossley Associates, in Chicago. He was so mad at Packard, he went back to the Midwest. Those kinds of upsets didn't happen often, because both Bill and Dave were exceptionally humane managers.

It was a great time to be working in the lab, and I really learned what I didn't know. The one thing I'd never learned was circuit performance analysis. I'd taken fundamental courses and all that, but I'd never really analyzed the performance of circuits in a way which demonstrated their limits. You might exchange some component values, on either side of nominal, and plug in a bunch of different tubes. If they all worked, that's good enough. For the most part, the designs were pretty reliable, but it was a far cry from the solid engineering that HP achieved as the years went on. We used a lot of reference books, the MIT Radiation Lab-series reference books were invaluable. We also had lots of previously-successful pulse circuitry, delay vibrators, etc, which we would adapt. I'd never had all that kind of precursor of digital circuitry in school or in the Campus Electronics Service or in my own hobbies. It was all new to me.

Dave or Bill would come around fairly frequently, and they'd just sit at your lab bench and talk to you and go over what was happening. If you were having any problems, you'd talk it over. It was very low key. They were just very present and very constructive. They helped you talk it out and their help was almost taken for granted. They were the real technical guidance. Brunton had his own projects, and he was responsible for the stock room and other administrative duties. I think officially he probably approved the pay raises, but I think it was more just a titular situation. He never came around asking questions. He was a bright guy, but was never recognized as much of a manager. It was Bill, more than Dave, who was best for technical advice. The 618B project went well, and it was finished in about a year. It was mostly a replacement for the 618A, with better modulation specs.

My next project was working with Bruce Wholey. Somebody had an idea of accurately measuring the width of frequency in a spectrum display. Essentially what you did was to modulate a carrier signal, so that you got the two side bands. By knowing the modulation frequency, you very accurately knew the spacing between the side bands. So you could just put that on a monitor and you could measure the spectrum width quite accurately. We built prototypes, but then it was decided not to make it into a product.

|

HP 335B FM Monitor. |

Next, again working for Bruce, I got involved in frequency monitors for FM broadcast stations. There had already been a previous version. I think Norm Schrock was involved in that, and maybe Gene Stiles. It used a pulse counting discriminator, and that was the big claim to tremendous linearity in the measurement. You could measure distortion in FM and know that you were measuring it, and not contributing to it.

I did some work on that and then I got the job of building a similar monitor for television stations. You needed to have a monitor, not only of the FM sound part of the signal, but also the AM video. I combined them so that you could measure the spacing between the video and the oral carriers, and display them on a meter. It's nominally about 4.5 megahertz. The FM circuits of the monitor were fairly straightforward, except that we used more modern parts than we had on the earlier ones. We also had a little bit more packaging on the thing.

One of the problems on the FM monitors was that broadcast stations often wanted a remote meter to put up on the operator's console panel. But our meter operated on voltages that were up on the plate voltage circuitry, on the pulse counting discriminator. So it was about 200 volts above ground. If you happened to connect it at the wrong time, you made a motor out of the meter and destroyed it. One of the things I did was to design that display meter down at ground potential.

By that time, Al Bagley had been working on frequency counters, and had some improved ovens for the quartz oscillators. So we used the new ovens to get better frequency stability to control the crystal temperature. I can't remember what kind of a switch was in the thermostat, but one of the problems had been the oven heater was controlled directly by that switch. This was causing arcing and some failures. I used a vacuum tube to control that problem. I can remember talking to the RCA people, because this was something that would be on all the time, and would need to last forever. I asked them what the most reliable tube was, and I think it was the 6SJ7, connected as a triode. So that's what was in it. By running at a very low filament voltage, I estimated it would last forever. As far as I know, none ever burned out. It was an interesting project. It was the first one that I really did by myself, so I got to write the instruction manual. We all did those jobs, and talked to the field reps about their customers. We also trained the people out in the test department. In fact, I actually tested the first one or two runs.

|

HP 335E TV Monitor. With the post-WWII growth of TV broadcast technology, the US FCC wrote specifications for stations to provide frequency monitoring. |

Our lab of that time even dealt direct with customers. In the TV broadcast spectrum of the time, there were eighty two different channels of television. Actually it was three times 82, because there is a plus or minus ten kilohertz offset on each one. This really complicated our production planning. We had to set up a whole program for aging these special crystals. It took a long time to age them, weeks. We didn't want to wait until the customer ordered to start ordering the crystals, because then you had the supplier production times added in. We had a couple of crystal suppliers. Monitor was one, and James Knight may have been the other one. We set up a whole program for ordering a couple of hundred different crystal frequencies, and then aged them all. We built burn-in racks, recording the frequency daily and watching them until they finally stabilized.

I remember a couple of events of that time that were rather interesting. When there were monitor problems in the field, I was the only one who could answer them. I usually answered them by phone and talked to the field sales people. I remember there was a station up in Sacramento, that couldn't get the monitor to read right. I couldn't seem to fix it by phone, so I loaded all my test equipment into a station wagon and drove up to Sacramento.

I began measuring with a frequency counter I had brought with me, and I went through everything. I finally concluded that the monitor had the wrong crystal frequency in it. I remember calling up Bruce Wholey, who'd been working very closely with me, and told him what the channel was and what the offset was. I asked him to, "calculate the correct frequency for the crystal." He did, while I waited, and he gave me the number. I said, "That's what I get too," and that was not the number that was in the monitor. We had made a basic assembly mistake. I'd probably made it myself, and we'd ordered the wrong crystal, aged and tested it and put it in. That was rather embarrassing.

Another time there was a station on top of a mountain near Bakersfield. They called and said their HP equipment was way off, and they couldn't get it to read at all. Again I drove down there with the station wagon full of test equipment. I sample probed with the frequency counter and did all the checking around. This time I concluded the station was actually broadcasting on the wrong frequency. The monitor was working perfectly.

They said that was impossible, because they'd had a frequency-monitor service company pick them up off the air and read their transmitter frequency. We then calculated everything and found that the service was using a beat frequency technique, in which you generated a harmonic and then measured the low frequency. They just multiplied by the harmonic number. The answer was that they were off by one harmonic number. When they finally figured it out, the station guys were apologetic as hell to me, and just madder than hell at the frequency service, that they were relying on. You know, they'd tweaked them in on the air, measured and then told them to shift. So we adjusted it and got them back on their legal frequency. Of course most FM listeners wouldn't know the difference, since their FM radios were analog tuning at the time. Today's digital radios would never find such a station.

After they were back on their authorized frequency, I had all this test equipment with me and they asked if I'd mind checking all the other equipment as long as I was there. We checked the calibration on a lot of their oscillators, signal generators, and other equipment. For me, it was an excellent experience of being on the front line dealing directly with real-life customers.

In one sense, our lab and marketing groups were so small, that in those days an engineer at HP was almost a business unit. Besides designing products, you did some marketing, and training and servicing and a whole bunch of things. You were in charge of that business area. It was one of the best personal training spots you could possibly have. For instance, if you wanted a chassis, you laid it out flat, and then you went out and got the piece of sheet metal. You sheared it to size, notched the corners, taped the layout on and center-punched, where all the holes were located. You punched all the holes, and folded it up. If you wanted a clean-aluminum look, you took it over to the bright dip tank. You did the whole thing, and it was just our ordinary way of business.

For us engineers, it was a great work style, and you made the whole assembly from drawing to finish. For me, it was not only personally interesting, but it also had something to do with the kind of management we had. It was the trust that came down from higher management. I'm reminded not only of our own projects, but that management trust was also evident when Bill and Dave decided to send Ray Demere over to Europe. They just told him to start a little manufacturing company over there in Boeblingen, Germany. And they told Bill Doolittle to start the European Sales operation in Geneva, Switzerland. Doolittle came out of production, with no sales experience at all. They had a great trust in our people and what these people could do if you just gave them their basic objectives.

For the TV monitor, I was reporting to Bruce Wholey at that time. Also at that time, Dexter Hartke was involved and did a lot of the RF work. I think he did most of the RF section of the monitor. He was a fine designer. At that time Wholey had the high frequency and microwave projects. Al Bagley had his section and was working on counters separately. Keith Hunton and Pete Lacy were working almost independently of Bruce, assigned to the high frequency components like waveguides. They tried me on that technology once. That was before the TV monitor. They wanted a waveguide directional coupler. Someone had read an article and they asked me to make, what was called a beta hole coupler. It was an array of multiple holes on the flat side of a section of waveguide, which coupled power from one guide into the other. One feature of that design is that the coupled power flowed in the same direction in the second guide. I built them according to the recipe and tested them and see the performance. What the coupling factor was, and what the directionality was. Boy, I surely didn't understand that stuff, but the results were pretty good.

My next project was an oscilloscope. We had moved the lab from being just half of the middle room in the Redwood Building, to the back of the Redwood Building. It was numbered 7A. The company had expanded to two "concrete" buildings, numbered 7B and 7C. We outgrew that and then they built Building 8, the saw-toothed roof building at the corner of Page Mill and Park Blvd. Norm Schrock was in charge of the oscilloscope section, and I reported to Norm. I was responsible for the horizontal section, which was the sweep generator circuitry and the horizontal amplifier.

|

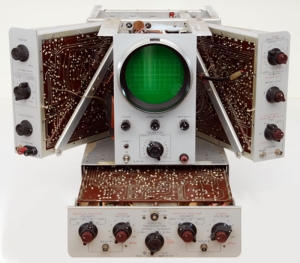

HP 150A 10 MHz oscilloscope, showing the horizontal and vertical amplifiers on the swing-out modules. Input signal conditioning was in the slideout drawer. |

This project was the infamous 150A. We were all trying to be very clever and outdo Tektronix on performance. So we decided to put the CRT tube in the middle of the oscilloscope. Printed circuit board technology was just coming into use, so we decided we'd use them. We had two foot-square printed circuit boards on either side, on swing out panels. "Dumb" Tektronix used DC on the tube filaments to cut down the hum, but they had all the vacuum tubes in parallel, and we knew better than that. We put all the heaters in series and ran them with high voltage like Christmas tree strings (and the commercial radio receivers of those years).

That idea certainly made the power supply simpler, and eliminated a low voltage transformer. But it also gave us some hum pickup. The real fatal flaw for that time was that printed circuit boards themselves were having serious problems. They were one sided boards with eyelets you could poke the laminate off. We had no PC layout help, so we laid out our own printed circuit boards, for the photo-etching process. We'd design them and lay them out, then drill the eyelet holes, and etch them, the whole thing. That was a very educational project.

We were finally ready to introduce our great scope contributions to the technical world at the annual IRE show in 1956, in New York City. There were two products, the 10 MHz, HP 150A and the 500 kHz, HP 130A. So we built a small quantity of each to bring to NYC. We were working night and day, literally, to get them ready and shipped. HP marketing had the foresight to have a large suite reserved at the Waldorf Astoria. We brought all of the models into this suite so that we could make sure they hadn't suffered any damage in shipment.

This turned out to be a VERY wise decision, because all sorts of wires had come off the various controls. There were lots of switches on the panel, and then these little connector pins which pushed onto the printed circuit boards were intermittent. We hadn't left enough slack in the wire and they'd disconnected. We'd brought test equipment, so we set up a whole lab right there in the Waldorf suite, and checked out every instrument, and got them all working again.

Inexplicably, New York then had the greatest snowstorm they had seen in years, a couple of feet of snow, and you couldn't even get a taxi. There were no cars running at all. I can remember carrying all those oscilloscopes through the snow over to the elevated railroad. We were showing at the New York Armory, which was way up north in Manhattan. We had to carry all this equipment over to the elevated and take it up all that way. Everybody on the train hated us because we were taking up so much room, and they were crowded because of the storm. We got up to the Armory and we got through the show and demonstrated our great contribution. It went fairly well.

After the show, I remember several of us, including Packard, myself and Norm Schrock went up north to IBM. We took the two new models up there in the car, and when we arrived, either the 150 or the 130 wasn't working. Packard was the marketing guy, and he was doing the presentation. He did all the presentation with both instruments sitting up there, but he said, "For the economy of time, we'll just demonstrate all the features on this one instrument. They're both the same except for the difference in the vertical band width." Nobody knew the difference. I don't think we made the sale, Tektronix was so entrenched.

Driving back, the roads were slipperier than hell. I was driving. We came down a hill and the car went into a skid. We did a complete 360 ground loop, and ended up on the shoulder. Fortunately, we didn't tip over or anything like that. Packard looked over and said, "I'll drive."

Of all of our various lab projects, oscilloscopes were the most challenging. It is company legend that initially HP did a lousy job of implementing scopes. We were up against a competitor who had done a very good job, and we didn't really build on what they'd done, we just tried to be different. We didn't really have much contribution to make, that was better than what was already out there. I think that that was a real weak situation. However, our 120A and 130A low-frequency scopes did fit a profitable niche where Tektronix had not occupied.

It was much different from the situation later on, when we got into spectrum analyzers. The competitive ones on the market from Polarad and other companies were not good. HP came out with the HP 8551A, and due to an excellent engineering job, and the marketing perception of it, made it a winner. It had a calibrated vertical and a calibrated horizontal display. These were performance things you could really measure with, and it was an excellent contribution. In the oscilloscopes, we just didn't do this, partly because some of our Sales Reps had lost the scope line when Tek went with their own in-house field engineers. So the project was rushed. This situation continued on for a number of years. It wasn't until we got into the HP 185A sampling oscilloscope that we really made some basic contributions that gained us a viable scope position.

We probably should have gone to the following New York show, a year later. I think we had decided we could be ready technically, and we probably advertised that it was. It wasn't our normal, conservative approach, that we should have had, and particularly in a product line that we didn't know. Bill and Dave were totally knowledgeable (and realistic) about where we stood, because I can remember that last night, before we went back to New York, they were in the lab until way after midnight with the rest of us tweaking the demos. So we were all in it together. We had made the commitment and, we were going to show it.

That was particularly painful, I think, because one of the big features we put in our first scope ad was "reliability," and due to the rush, it was not nearly as reliable a scope as we would have liked. We tried to do a lot of things, like the delay line for the vertical signal, so that you could pull off a trigger, and be able to trigger on the signal you're looking at. Tektronix had a discrete component delay line and we decided that was a clumsy way, and we'd just put in a hunk of cable. We got some delay cable and put in a piece about a foot long. That was probably okay to do that because it's bandwidth was not bad, but in a lot of cases we were just trying to do things differently for the sake of being different. That's very dangerous.

There was another interesting period in my life. It was the year when Bill and Dave were able to convince Barney Oliver to leave Bell Labs, where he had worked during WWII. He would come to HP, as the Director of R&D, and later as VP. This would have been about 1952. He came some time before the lab moved from the Redwood Building over to Building 8. Building 8 was located at the corner of Page Mill and Park Blvd, closest to the railroad crossing. While we think of Barney as a scientific genius that he was, it was Barney who invented the standardized HP lab bench design that we used for many years. The new building was outfitted with those.

He regularly came around to talk about the projects, but at the same time was evaluating his engineers in his R&D group. He was probably tremendously chagrinned about all the nincompoops like me, who didn't understand any of this analytical stuff, as he tried to explain poles and zeros. So he set up weekly lectures on different topics that we should have already known. He also included some very effective demonstrations.

The one that I still remember was on square wave testing, because that was really hot stuff at that time. For characterizing an amplifier performance, the standard method was to run a frequency sweep, to determine the response curve. But, instead of sweeping across with sine waves, he said, "Why don't you just put a square wave input, and if the output comes out square, your frequency response is in good shape." Everybody acknowledged that was true. He had a demo black box, and he input the square wave, and looked at the output on the oscilloscope. There was a nice square wave. He changed the frequency just flipped the range switch ten to one. Again, there was a nice square wave on the scope. He did that several times and said, "What do you think about the frequency response?" We said, "Flat."

Then he replaced the input square wave with a sine wave and the response went up and down and up and down. He had all kinds of tuned circuits in there that we were totally missing, by the harmonics in the square wave. It was the weirdest up and down type of thing. But by choosing the right frequency for the square wave, which he had done, he just straddled every one of them. We all learned that Barney's specialty was math transforms, from frequency to time. And he was very adept at converting from electronic to mechanical or fluid systems. If an electronic circuit was misbehaving, he would mentally convert to say, the mechanical analog, and think it through that way.

I can remember his lecture on reflectometers. This explanation also involved seeing the difference between inductance and capacitance and resistance, in a transmission line, and how to detect all that by just the wave shape. It was pretty fantastic to have such a brain as a backup to our scientific advances.

About 1956, Bill and Dave decided there were opportunities in the measurement systems business. They wanted to be able to take advantage of HP's knowhow and technology in our products, and leverage that into a systems business. They had hired Bob Rawlins from Lockheed, down in the Los Angeles area, to come up and head this new operation. All along, whenever I had talked to them, I had always expressed an interest in getting into industrial electronics. That's what I had wanted to do before I joined HP, and all the projects I worked on, like TV monitors and oscilloscopes, weren't really industrial electronics. It was just test equipment to test other electronics.

I don't know whether it was to get rid of me from the lab or not? But they said they were setting up this new division to do systems work. Would I be interested in doing that? I quickly said yes, without knowing much about what they intended doing. It sounded to me like it was a lot closer to real electronics than what I had been doing. They told me they'd hired this guy Bob Rawlins, and I would work for him. I said, "Fine, I'll do that." I was sitting at the Editorial bar in New York City, having a drink, and that's where I met Bob Rawlins. I said, "You're the guy I'm going to work for." We hit it off, so after I came back from the New York show, I transferred over to work at Dymec. There were just Bob and Dave Stead and maybe a couple of other people at the beginning, so I was probably number three or four person to go over there.

|

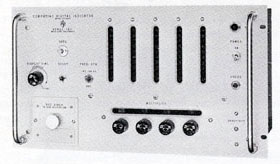

DY-2500 computing digital indicator. The knobs set in a selectable time-base, so the display could directly read out physical units, like PSI or RPM. |

I got involved with a special counter that Al Bagley's group had as a pet project for a long time. We ended up calling it a computing digital indicator (CDI), because it was a frequency counter with an adjustable time base. It was intended to take over a product sector from EPUT (events per unit time of Berkeley Scientific). We thought CDI was going to do it, so we built this frequency counter, and then provided at the bottom, knobs that could input either four digit or five digit numbers. These number inputs essentially adjusted the time base so that it multiplied the normal display by a selectable constant. This was a powerful feature because it allowed the display to show actual engineering units. Thus it was particularly useful for physical measurements, like pounds per square inch or RPM or whatever.

So a person couldn't accidently dial in the wrong number, we also had plug on the front that could be wired with a constant number in it. When it was plugged it in, it couldn't be changed. So that got us into the industrial type of things. Al Bagley coached us throughout that whole project, with his electronic counter expertise. We used the standard F&T division output staircase it to drive printers. It was a darned good product that got us into a lot of industrial applications. Later on we offered other transducers, like a pulse counting tachometer which had a little etched wheel and a photodetector that would put out 360 pulses per revolution. We counted that and measured RPM.

|

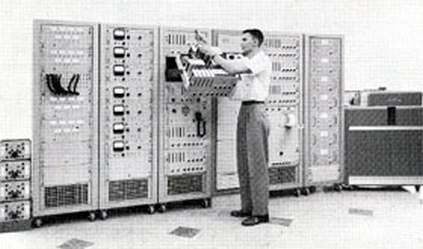

DY-5001 scanner was a data acquisition winner for aerospace structure testing. |

Then customers began to slowly get us into the data acquisition system market. It was not too slowly, because Bob Rawlins was pretty aggressive on selling. The very first system that we sold was to Boeing. These were big days for aerospace, and they had to do an enormous amount of airframe performance testing. It was the DY-5001 system and it was intended to replace their current wind tunnel measurements of air pressure. The conventional way they were doing it on wind tunnels was with whole banks of manometers, each of which were measuring pressure drop across the model in the wind tunnel. They would photograph each channel and then take it off by visually reading the manometer photograph. On a one-shot, blow-down wind tunnel, there was a finite amount of time before the pressure tank ran out of air. So they went through this tedious process of taking a manometer photograph on one model position, change the position of the model, take another photograph and then later on read all this information off.

The idea with our data system was that you could do this all automatically. There was a pressure transducer product, made by Byron Jackson Company, which they called a Vibratron. It depended on a resonating wire, attached to a diaphragm. As you increased the pressure on it, the wire became slightly more slack, and therefore, the frequency dropped. However, it wasn't linear, so this got us into some calculations to do data corrections before recording. We built electrical circuitry that could take that curve and make it read out directly. We used the circuitry of the computing digital indicator to make the corrections, so that the thing would read out correctly. This system had twenty or thirty channels of pressure transducers, and then the corrected outputs all went to magnetic tape where we recorded the combined data output. We had to have a box that would put all this data together, and format it onto digital tape, to be read back later. It was about a six bay system and it was quite a challenge.

It was interesting that as time went on, and we built more and more systems, into standard rack cabinets, that we later were surprised, that when we priced out such systems, the price always came out quite close to $1000 per vertical inch. So a 6-foot high rack full would be around $72,000. That turned out to be true whether it was full of microwave instruments or data acquisition instrumentation. Fascinating.

The first data scanners we built were stepping-switch scanners, using telephone-technology stepping switches, but they were fairly slow. One reason we did that was that that technology was old and VERY reliable. We used those switchers mainly in voltmeter systems. Their electrical contacts were gold plated and had relatively low voltage offset, so we could scan up through twenty five points and connect it into a voltmeter. We could then record on an HP printer, both the channel number and the reading on the voltmeter. Later, moving up performance from the stepping switch scanner, we started designing in the cross bar scanner technology. Again it was a telephone standard usage, and we could handle something like 100 by 100 by 6-wire connections, or 200 three wire connections. They were faster than a stepping switch. They could also be random accessed, if you had a way of programming the switch. Then, much later, we got into Reed relay scanners, which were much faster.

As Dymec started, I joined engineers Dave Stead and Jack Humphreys, all there within a couple of months of each other. There was no particular assignment as "Chief Engineer," it was just a small group of busy engineers, just out of default. But what happened was that soon after we designed the early equipment, the same engineers had to build it. Initially, we were all in the very front room of the Redwood Building, which was 1500 square feet, and initially the production line was right down the middle of the room. We had Nelly Monsees and Zella McFadden and a few other women transfer over from HP to do the wiring.

When people needed something, I started getting it for them. If we needed equipment, I would order it and I slowly worked into the production details. Then when production finally outgrew the Redwood Building, we rented 440 Olive Street, and we moved the production over there. We obviously needed a purchasing agent, so Dale Dewitt transferred down and ended up reporting to me. Then we needed production control, and Fred Becker transferred in to handle that. Soon we ran out of space again, and I found another building at 440 Pepper Street and rented that. It didn't have a bathroom, so I designed a bathroom, and got it installed. Our stockroom was conveniently in the next building 7B, and we outgrew that, so I rented a building down at the corner of Park and Lambert. Again I had to go in and design and build a toilet and do the lighting and move the stockroom down there. So, as you can see, I was just kind of assuming the role of Manufacturing Manager.

In the meantime, as production boomed, we wanted to do our own sheet metal work, so Gordon Smith transferred over from HP and he and I worked together. He'd tell me what he needed, and I'd order the equipment to set up a sheet metal shop. We got Jack Tennison to run the sheet metal and Gordon was over all supervisors. He also built our machine shop. We outgrew this, so we went out and rented another building on Park Ave. It was crazy, because at one time we had five different addresses in South Palo Alto. We used a little electric cart for transport between buildings, and then we bought four or five bicycles so that we could ride between the places. We just had a great time throughout that whole period. The group over at 440 Olive, which was mainly the wiring and assembly and for a while, the test group, was very close knit. I was over there frequently and we got along very well.

We had two sets of production processes. For products that would be made in small quantities, we had the people who had regular wiring & assembly skills. They worked from a sample model and just copied it. For the one-off quantity, we used electronic technicians who worked from schematics. They were real craftsmen, and did beautiful work. The engineers would just draw up circuit schematics and give it to these technicians. They would come up with shippable, first rate quality. In one sense, Dymec products were a bit like the work I did before, at Purdue, when we designed and built custom electronic equipment for the other school departments.

It was satisfying to me that the people of Dymec were able to exist in two product markets. One of them was our "standard product" business, where we would go through the normal HP new product process, with prototypes, and a concern for production thinking, serious documentation, etc. That example would be the DY-2401A digital voltmeter, which was sold to customers individually for integrating into their systems. The other part was the digital data acquisition systems. These consisted of a scanner for connecting to the customer scanner points, then a system-oriented voltmeter or frequency counter for making the measurements, and then various output storage devices. These might be punched paper tape or digital printers, or magnetic tape and other recorders. We sold most of those system elements, either as individual components or we combined them into systems.

Another part of the systems business, which we were pretty good at, was a microwave signal simulator that was configured to check Doppler radar systems. At that time, HP did not have programmable frequency synthesizers, or other ways of generating precise microwave frequencies. For the Doppler performance, we wanted to simulate the radar return echo from a moving target. That meant that the return frequency was slightly offset from the emitted signal (Doppler effect). So we came up with what was called the serrodyne technique, which was accomplished by modulating the helix of a traveling wave tube (TWT) amplifier with a saw tooth. As we did this, the phase of the TWT output signal would vary, because it was proportional to the voltage on the helix. When the microwave phase shift got up to 360 degrees, the sawtooth snapped back and then repeated. So you had a microwave output frequency that was offset by the modulation frequency, the repetition rate of the saw tooth. That offset represented the Doppler offset, which we needed to test, and was able to simulate the radar target display.

|

The DY-6190A was a radar test simulator. It used a microwave travelling- wave amplifier, modulated by a sawtooth signal, which produced a constant loss of phase, ie, a precise Doppler offset from the microwave transmit signal. |

That was our basis for making signal simulators in various frequency bands to check out various Doppler radar systems. We made them in X band and C band and several others, and we sold them to General Electric, Hughes and Convair and a lot of others. They were very expensive and very sophisticated systems. We also got into some programmable parts. We needed some programmable microwave attenuators, so we designed motor driven attenuators, motor driven phase shifters and other types of passive components that were intended to be hand operated. A lot of that work ended up in classified, so we built some separate secure rooms, just for classified work in military contracts. It was a rather interesting time.

We got pretty good at "Rube Goldberg" solutions to making standard manual instruments into automated ones. For our data acquisition systems, we needed to take data into our system from Bagley's frequency counters. Fortunately Al's designers had already arranged an interface to their HP 560A digital printer, by use of 100 volt staircase outputs, one wire per numeric display digit. The staircase advanced 10 volts for each digit increase, 0-1-2 etc. While it was very economical of the interface wiring, it was not as common as a BCD code which took 4 wires per numeric digit. Our guys adapted to both standards.

|

The HP 5105 frequency synthesizer was precisely accurate, using the manual pushbuttons, but for programming, it required 10 wires PER DECADE. |

Then we came to the HP 5100 frequency synthesizer family from Bagley's F&T Division. Customers needed this capability for programmable stimulus signals for their test systems. The synthesizer had ten push buttons on each decade, so there were ten wires for each decade of the frequency input. We at AMD had pretty much standardized on BCD code, so one of our first custom designs was a decoder from BCD to ten wires to run the synthesizer. This was needed for all 10 digits of input of the 5100.

The name of the game then was that very few of the products that HP made were very system oriented. I'd say that the digital output from counters was very much on purpose because they had to drive printers. External programming on anything else around HP was almost an afterthought in most cases, including most of the other counters. They had knobs on the front panel, but if we wanted to change the gate time, it was just too bad. We couldn't go inside the box to replace a multiple layer mechanical Oak rotary switch. So Dymec just accepted that as a given, the fact that one of our roles was to take instruments as they were, and modify them. If we couldn't get the division to modify them or the external supplier to modify them, then we'd modify them so we could control them, or get data out of them.

We built programmable "knob turners." That was the outgrowth of some of the work we did on the microwave signal simulators, where we were turning attenuator shafts and turning phase shifters and things like that. So we designed motor driven shaft tuners, with optical shaft encoding for precision settings. We adapted that to other types of instruments. Whatever it took to get the job done was essentially our task. Most of the divisions just didn't want to be bothered with such modifications because the volume was so low.

But Bagley remembers that finally the message came back to the divisions. They kept hearing from Dymec more and more, and other customers, that there was something to do with systems that made measuring automated. These persistent rumors finally stimulated somebody to say, "We ought to have something like a common programming language so we can talk between instruments."

And it wasn't just Dymec though. The world was going that way and all of the internal system houses of the major companies were wanting the same thing. So it was a ground swell everywhere; but unfortunately, for many, many years every instrument had a different interface. It was much, much later that the HP Interface Bus came along, with the idea that you should have a standard interface. Dymec just went at it and sometimes it was more than just a simple connection.

I can remember particular problem instrument was the HP 8405A. It was a 2-channel RF Voltmeter to 1 GHz, with also the measurement of the RF phase between channels. It was supposed to lock onto the test signal coming in. We would program a signal source, then we would get two analog signals that we could run in, and measure. But sometimes it wouldn't lock on the test signal, and that was disastrous for an automatic system. I can remember talking to the people in the Stanford Park Division. We tried to figure out what to do, when it would occasionally just not lock in. The engineers said, "Well, you turn it to such and such and then you turn it back. If it doesn't lock in, then you try it again." So what we essentially built into the software driver, in case it didn't lock in, was a good kick.

Back to management. The hiring of Bob Rawlins from the outside, to manage a division was unusual. Up until that time, HP almost never hired a management person with a lot of experience, from the outside, and put him into a fairly key job, like they did with Bob Rawlins. I guess bringing Barney Oliver into HP Labs was a first, but he was a personal buddy from their days at Stanford with Bill and Dave. We almost always said we wanted to grow our own talent. But I think Bill and Dave had known Bob, at Lockheed, for some time before. He was probably a customer, and they shared a mutual respect. Bob also had very much of a can-do attitude. He would go out and commit to all kinds of complicated systems, and he had no fear of negotiating. Compared to most of us around there, who were just engineers, he would not hesitate to do estimates and calculations, set a price and specs and sign the contract. So he was someone HP needed at the time.

Bob and I got along extremely well. I learned one helluva lot from him. Traveling with him on the road was an adventure in itself. His internal clock ran different from most. Being in a plane five minutes early was wasted time. He was extremely uninterested in the actual engineering and manufacturing. He seemingly could care less how things got designed and built, no matter the complexity. That turned out great for me, because anything that I decided to do was fine with him.

I ended up becoming the manufacturing manager, more or less out of default. I just got out of the engineering part of it, and we just built stuff, tested it and shipped it. That was fine and I got great satisfaction out of doing that. We had a lot of fun, and the relationship with Bob was just great. I liked to set up parties, so I ended up running the parties and the beer busts and the picnics. While we worked REALLY hard, we had a fabulous time. Dale Barger was head of the microwave engineering. Harry Schultheis was in charge of the digital stuff.

Ed Morgan headed marketing, although Bob, himself, really did most of the sales end. Ed would handle the old-HP part of the standard products. At that time we had Sales Rep organizations, and annual negotiations with the reps was an ongoing activity, particularly on commission rates. One good thing was that Morgan was on good terms with Noel Eldred, who was the main HP connection with the independent Rep companies. Ed's step-father was Frank Cavier, V.P. of Finance. With these custom systems, the reps could only be a finder, because all the customer negotiations had to be between the customer technical staff with our own Dymec engineering. Bob usually led those negotiations, along with our people in the engineering department.

The real challenge came when Rawlins would have to quote not only price, but fixed delivery on something that had never been made before. Engineering would get consulted, and we had to lay it on the line, and try to come out right day in and day out. To this day, being in the custom system business is one of the toughest engineering environments around, because you can estimate correctly nine times out of ten, but if you guess wrong once, you can wipe out all the profit on those first nine with that one bad guess. Further, we didn't get a lot of repeat business for the same systems.