HP Memories

ForewordMr. Colorado Telecom---Al Steiner How did brand new HP marketing engineers like Al Steiner learn how to manage their future enterprises? In the Microwave Division Marketing Department of 1964, there was the beginning of an evolution in the way Hewlett-Packard managed its rapidly growing company. In 1962, Bill and Dave decided to divisionalize operations, which had previously been centrally organized and controlled, more or less from the top, as one might infer "Management by Directive." All the labs reported to Barney Oliver, all manufacturing to Noel Porter and all marketing to Noel Eldred. In that year of 1964, John Young moved up from Marketing Manager to Microwave Division General Manager, and brought professional management procedures into HP. I like to refer to Bill and Dave and Eldred and Porter and all the others as intuitive managers. They were engineers who grew into their management roles, and without a doubt did it beyond well; they did it superbly. But the company was on a growth roll, and management planning processes needed to be institutionalized. I can still recall when John Young asked me to assume his then-open Marketing Manager slot. One of the first things he told me was we needed to do a Marketing Audit. He was a Stanford MBA, I was a Stanford MSEE, and I had no clue. I couldn't just look it up, like now when you just Google "Marketing Audit." What John wanted was to step back and see how we were handling all our marketing functions, considering technology, customers, business environment, financial, IT and such issues. We were to look at our marketing department functions in detail, and compare them to successful industry and ideal practices to change our department culture. John proclaimed that the central business strategy of HP was to invent and successfully introduce new products, which would layer up on past vintages of older products. He pronounced that we should target a growth rate that would exceed the average HP corporate rate of 15% per year. John intended to execute this central business plan by a formalized new product plan process. The objective was to have a continuously updated 5-year-forward new product planning document. The ownership of the 5-year plan was in the R&D Lab, but inputs were demanded from marketing that supplied customer's new system requirements 5 years forward. The lab would plan based on upcoming new design technologies. The manufacturing managers would supply forecasted improvements in fabrication processes, which exploited new production ideas. There would be a Wednesday morning product planning meeting, with each of 4 product groups being seen once per month. This put the new product plan in the hands of some very young, but capable, engineers and MBAs. Their plans were being reviewed monthly by the Division management team. The Microwave Division was right at $20.4 million annual shipments. I had never managed a group of several dozen people before, but we clearly needed aggressive recruiting and team building and solid coordination with the lab and manufacturing. Although I had only a couple of years in the military, I used to consider our high tech industry situation to be similar to a military organization. In those long-tested command structures, you had a continuous influx at the bottom of brand new enlisted recruits and brand new 2nd Lieutenant officers. And you had quite a lot of upper level command officer rotations too. So those military commands had to learn to be efficient and team-centered and successful--some would say highly successful--with all those changing constraints, sometimes right in the heat of battle. So in my mind, newly-hired sales engineers and marketing and service engineers were 2nd Lts. and new MBAs might be 1st Lts. (Recall that military specialists like doctors and lawyers were commissioned directly to Captain rank.) My Product Managers and Sales Support Managers and Service Managers were first line managers and were equivalent to Captains; more experience, more hard knocks, more expertise. Product Marketing Managers and Sales Managers were Majors. And as Marketing Manager, I was a Lt. Colonel. John Young, our Division Manager was a Bird Colonel. So all my bright young BSEE and MBA hires were coming in rapidly, and filling all those technical marketing process jobs, as the first and second lieutenants. And here came 1st Lt Al Steiner (Harvard MBA), also, just graduated from the Carl Mahurin "Charm School," of technical measurement training and "How to write superb letters to customers." Al went to work on spectrum analyzer products, as the blockbuster HP 8551/851 analyzer just rolled out in 1965. It hit $10 million dollars per year in about 2 years. Al was relatively quickly promoted to Spectrum Analyzer Product Manager. It was a magical time for all of us in microwave marketing. We were growing at twice the average corporate rate, and by 1969 we had tripled our annual sales, while the corporate rate only doubled in the same 5 years. Young managers like Al quickly learned principles of good management, and developed an amazing teamwork with their own lab group and their own production team. They could see the elements of planning and execution. They not only performed superbly, but soon they were ready for advancement. In Al's case, he was known around the corporation, partly because of the visible success of the 8551 and it's follow-on products, and here came a job offer from Al Bagley to jump to a division marketing manager position in the F&T Division. Al's life memoir is exciting. As he advances in responsibility and breadth of management control, he shows the best of the HP spirit, he is a compassionate manager, a consensus builder, good with team-building and managing rapid growth. Even with his debilitating medical challenges, he perseveres and succeeds, largely because the team he built before his medical problem was able to carry on for their boss, and made success happen. Interestingly, Al was just one of a cohort of young managers who emerged from Young's original microwave division to grow to do great things at HP; from marketing; Ned Barnholt, Dick Hackborn, Scott Wright, Hal Kramer, Doug Chance, Doug Spreng, Marc Saunders, from the lab, Paul Ely, Dick Anderson, Rod Carlson, from manufacturing, John Doyle, Tom Lauhon, Dave Weibel; and the list goes on. Remarkable. I can't help but relate one final meaningful story. I left my marketing manager job in 1969, to work several years on light-emitting diodes, and later a couple years in automatic measurement systems in Sunnyvale. But I got tired of the commute, and one day I asked Al, who had come back to my old job as Microwave Marketing Manager, if he would watch out for a position for me in Palo Alto? Al literally told me that very minute, to come back to microwave marketing the next week, and he would figure out what I would do. By pure chance, a marketing communications assignment was just opening, a job I loved and worked on for another 22 years. I was pleased to be out of the management stress, and leave that up to other Lieutenant Colonels like Al. He soon moved up to Bird Colonel when he took over the Delcon Division, moved it to Colorado, and renamed it the Colorado Telecommunications Division (CTD). And, on to a great HP adventure. John Minck |

![]() Click

here to download Al's memories in PDF format - The 24 page

document is a 1 Mb PDF file.

Click

here to download Al's memories in PDF format - The 24 page

document is a 1 Mb PDF file.

I was born in San Diego and lived in La Jolla, CA until I went away to College. It was a rather idyllic life with a wonderful family of intelligent, loving parents, and 2 brothers with whom I am now close. Time was spent studying, working, cycling, surfing, enjoying friends (many life-long) at dances and beach parties, playing the piano, and dating girls. I enjoyed track and field (sprints and shot put), and won the city finals in the sprints and relays. In many ways, it was a blessed childhood, and I learned strong values from my parents and developed the basics of my Christian faith.

While working at "The Great A & P Tea Company" bagging groceries the summer before my senior year, I saw a lovely girl walk in with some friends, and I dropped the bag I was holding. I asked a friend in a younger class who she was, and called Barbara up for a movie date. She was 15 years old and asked her father, who was a retired naval officer and worked in a local bank, if she could go out with me. He asked, "Who is it"? When she told him, he said, "I know that young man. He comes into the bank every week and deposits his check into his account. Yes, you can go out with him!" The following year, I threw her surprise 16th birthday party for her. Thus began a romance in July 1958, which has lasted to today.

I was one of five students, out of the 1959 La Jolla High School class of about 220, who were accepted to Stanford. We all were ecstatic. I started majoring in Physics, which I loved, and worked with their small on-campus nuclear reactor. Many of my professors were the authors of the textbooks we used. By my sophomore year, I began to realize that my career in physics would likely be in research or teaching. It wasn't what I envisioned myself doing, so I switched to Mechanical Engineering. At the same time, I realized that my track career was going to be very short — there were others much better than I who were not pursuing an engineering degree. Barbara started at San Jose State at the beginning of my junior year. She would be the first college graduate in her family. I joined a fraternity, SAE, which was one of my best decisions. They were a wonderful group of young men and "little sisters," who enjoyed singing, intramural sports, and studying, and with whom I have maintained enduring friendships.

During summers, I had jobs driving a fork-lift for Sears, designing air conditioning systems for Pacific Telephone, and designing microfilm storage systems for IBM. By the start of my senior year, I realized that as much as I enjoyed the rigor of engineering, a career designing things wasn't my passion. I enjoyed managing projects and leading the efforts of a team. So, I applied to several business schools and decided on Harvard, partly for its excellent reputation, and partly because I had never been out of California and would be required to drive across country several times in my '57 Chevy convertible. In retrospect, my father's career path of a technical education (Stanford BS, MS, and PhD in Chemical Engineering), then on to technical management, may have influenced my decision as well.

My transition to studying business, particularly using the case method, was the most challenging one I had experienced to that point. I was one of the youngest people in the class, and had never had a full-time job. With no working experience from which to draw, answering the question. "You're the CEO! What would you do and why?" was next to impossible. Many in the class had had management jobs or military command experience, and I learned a great deal from them. It took quite a few anxious months to learn how to study and prepare for class discussions.

|

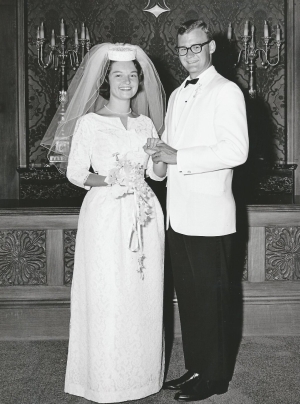

Barbara and I have been married for just over 50 years now, so she has experienced all of my HP years. |

Barbara and I were in regular communication and she was getting impatient to "firm up our relationship"!! 1964 happened to be leap year, so on Sadie Hawkins Day, she called and asked me to marry her. (She may deny that) I was smart enough to say yes. We were married the next summer, and she joined me in the brand new married student housing for my last year of Business School. She worked at Mt. Auburn Hospital to give us a little spending money, took classes at Boston University, and befriended other B-School wives.

I had focused on manufacturing and marketing and interviewed a number of companies in the East and Midwest, including IBM and Ford. It was the mid - 1960s and there were a lot of opportunities all over the country. Many of my classmates went to Wall Street into banking and consulting, but I had already made up my mind that I wanted to go into a technology-based business. Hewlett-Packard was one of the only west coast companies that came out to Boston to interview. I believe the team leader was Jim Ferrell, who was in manufacturing engineering at HP. The campus team offered a plant visit and I decided to come out. Of course I was already familiar with the Bay Area and Palo Alto since I had gone to Stanford for my BS degree.

At the plant, I interviewed with John Young, and a few others of the top management team in the microwave division and Corporate, all of whom were located at headquarters in Palo Alto. Even in that short time, the quality of the people and the attractiveness of the culture were clear. In consultation with Barbara, I decided to go with Hewlett-Packard. That was one of the two most important and successful life decisions that I made. The other was my decision to marry Barbara. I would say both of those decisions were blessed, in many ways. I graduated in June 1965, and we headed for Palo Alto.

At that point, HP was trying to figure out how to consolidate shipments from multiple dispersed divisions to a single destination. When a customer placed a purchase order with one of the local HP field offices, they might order a list of half a dozen different instruments. They would not realize or even care that those instruments would come from three or four different divisions. Often those various divisions were in different states. The problem on the customer end would be that for a single purchase order, with let's say six line items, it could cause some major paperwork problems in their receiving departments. The various boxes would arrive at different dates, some perhaps immediately, and some delayed by one or more months, depending on the production backlogs. HP wanted to set up a process whereby a customer could choose a shipment consolidation, for all to arrive within a few days.

This was happening often enough with some of our really important customers, that the feedback was hitting our field sales offices and the sales management; they wanted a solution. They began complaining to higher management levels such as Noel Eldred, VP of Corporate Marketing, our top marketing executive. I had some B-school familiarity with the more modern computer applications called linear programming that could do scheduling and coordination of shipments from multiple points. When I was hired, I was first assigned to Hank Taylor, who had a number of different responsibilities associated with production planning, inventory control and information technology IT over his years. I helped him set up the first freight consolidation program for HP.

Hank's HP story is a remarkable life memoir that is already in the archive of HPmemoryproject.org. In his memoir he describes his various functional assignments that put administrative projects on his shoulders that required a lot of creativity and internal salesmanship. Hank was a wonderful manager and he worked closely with me to make sure that I could get that project of shipment consolidation to be successful. At that time, he was leading the traffic department and ran other administration functions.

Although it was an interesting and challenging assignment, I knew I didn't want to focus on administration tasks. Fortuitously, I think it was John Minck, who was in some informal conversation with me, and agreed that if I was ever going to be managing technology at HP, I needed to get into one of the divisions. John agreed that I needed to supplement my mechanical engineering with a period in Carl Mahurin's "Charm School." The title, Charm School, got attached to Carl's training group by a wonderfully irreverent HP wag, Dean Abramson. Dean had worked in the Service Dept., before moving to microwave marketing to take over advertising. Carl was a curmudgeonly manager, and he certainly didn't fit the physical or personality mold of most HP managers.

Carl reported directly to Noel Eldred, and his primary job was to manage the repair center, which was quite a large operation. However, Carl was also responsible for product training, which included both internal training for new engineer hires like me, as well as field training for "Neophyte" field engineers. This involved several months out on a production line, doing assembly work. Or perhaps process work in the printed circuit shop. Mechanical assembly of an instrument would be to bolt together the raw chassis and heavy transformers and other large capacitors. These were then handed off to the production women who would solder up the wire harnesses and insert all the components and electronic parts. In addition to the production orientation, we would spend two or three months in the service department. In some cases we did actual instrument repair, under the guidance of a senior technician mentor, who was experienced on that group of failed instruments. We were also required to answer customer inquiry letters.

Carl was a hard taskmaster for this job, because he was a strident protector of every HP customer. Those stories were legend, because he would often make the trainee write and rewrite a letter maybe half a dozen times to get it to sound just right. The response had to be empathetic and to restate the problem, and then offer the solution. We had to read several well-known letter-writing texts like Strunk & White. The ultimate objective was that a brand-new college engineer, who never got any personality training or customer orientation at school, would come away with a new outlook on how they were going to treat customers. They were now speaking in the name of a brand legend, Hewlett-Packard.

The Neophyte Field Engineer training was a formal six-week training program, done in two different sessions of three weeks each. Brand-new field sales engineers would come to Palo Alto and receive technical measurement courses. In college, you might get some courses of the theory of how transistors work, or how transmission lines perform. Almost never was there any circuit design. You might take a laboratories course where you would run a few simple measurements, perhaps an audio amplifier performance. But you weren't likely to be exposed to microwave measurements, frequency standard measurements, fractional frequency deviation, network characterization, or oscilloscope measurements. So HP neophytes got modern theory, as well as current measurement experiments. Most new internal engineer hires like me, who were headed to marketing, would go through this neophyte training as well. Many of those student friendships lasted a career, as the field engineers went to work selling and began dealing with the factory engineer friends who were working in a division marketing dept.

That time was a real kick. It was the first time I was ever exposed to a person like Carl, whose management style was more of the variety of, "Let's go out and have a drink." Carl was an agronomist graduate of Stanford in about the same years as Bill and Dave. It's hard to tell how anyone determined that they needed such expertise at HP, but the need was apparently higher during WWII, so perhaps they were taking any educated people they could find. Carl was a member of the Elks Club and would go for 3 martini lunches. It was hardly the kind of training I was expecting to be exposed to as a business school graduate, but what he did was impress upon me how important it was to understand the technology and the customers' problems.

It was a microwave R&D engineer, one of the most respected, whose name was Stephen Adam, who made the best technical impression on me. In addition to his HP design job, Steve was also an instructor who taught microwave design at Foothill College, our local community college. I took that course from Steve, and afterwards actually taught with Steve. That was by far the fastest way to come up to speed on microwave technology. Recall that I was a mechanical engineer, not electrical. As a mechanical, I realized that a lot of the different phenomena like vibration theory and fluid mechanics had electrical counterparts. Those descriptive equations in the mechanical realm are basically the same as equations in the electronic and electrical realm. I would kid my electrical engineering friends in marketing when they would draw an electronic circuit diagram, by drawing a spring, mass, dashpot analogous diagram that had to do with oscillations. The analogies were striking, but they were a bit close-minded about it and wouldn't understand how a mechanical engineer could comprehend their electronic black magic.

I already knew I didn't want to be a design engineer, so I didn't need too much depth in the electrical technologies. I just needed to know enough to understand the customer problems, so that we could project the new instrument capabilities and functionalities that the customers would be require in the future. I had to be able to apply my insight to the symptoms that would come from customer feedback, and discuss it with an R&D engineer. So, after the charm school interval, I was asked to join the microwave division, which had been formed in 1962 as one of the first four charter divisions.

In 1967, I went to work for John Minck, who was the Marketing Manager, reporting to Division Manager, John Young. John Minck was a fantastic person and a terrific manager. I got to know him and his wife, Jane, quite well over many years. My title was Marketing Engineer, a level that was responsible for a particular microwave product. We had functional assignments like writing technical data sheets, and application notes to broaden customer understanding of how to apply our instruments to solve their problems.

|

The HP 8551A/851A Microwave Spectrum Analyzer, introduced two years before my joining the Microwave Division, had launched HP into this market, and now we needed to create new follow-on breakthrough products. |

Within a year or so, I was promoted to first-line manager, called a Product Manager. There were only 3 in HP at that time. The product manager had several marketing engineers working for him, each one assigned to a particular new product rollout. The product manager had to organize all of the functional steps needed to introduce a new product, as well as be responsible for new product planning. This new product planning process was a brand-new concept in HP marketing. John Young established a formalized review of a five-year new product plan. The plan was constantly being upgraded to recognize new technologies and new customer needs, but the value of it was that it forced all of us to pay close attention to what customers were telling us. We needed to know where their new systems technologies were going over what frequency ranges, and requiring new pulse rates, if it was a radar system. We needed to know what were the frequency stabilities of the transmitters, if it was a telecommunications system. What were the new modulations with the new data carrying transmitters, so we could match that with our new signal generator designs? Signal generators were like calibrated transmitters.

After about 2 years, I was promoted to Product Marketing Manager for Spectrum Analyzers. The R&D Section manager and I, with our Production Manager, really ran that business within the Microwave Division. The PMM's (Doug Chance and I) each had responsibility for all the marketing functions, except advertising, including Service documentation and training. This was a fun, exciting and challenging period, and those focused on the rapidly growing spectrum analysis business worked very well together, with quite a bit of autonomy. It was a very valuable experience to jointly run a business.

On a sidebar note, Dick Hackborn was also a PMM level manager, starting and running the Automatic Network Analyzer business next to us. I remember one internal promotion to the field he ran with the slogan "Any boob can operate it!" because it was such a complex system. His posters drew the attention of Bill Hewlett who was not too pleased. Your imagination can probably paint the picture of the poster.

John Minck moved away in 1969 to the LED group in the HPA division. There was an interim marketing manager assigned for about a year, and I think it was Ken Tingley.

|

Training Field Engineers in Geneva on a new portable frequency counter.

|

In 1970, I was offered the marketing manager's job at the Frequency and Time Division, reporting to Al Bagley. It was located mostly in Bldg 2, but was moving to Santa Clara, where it became the Santa Clara Division. Bagley's division was an entirely different culture from Young's microwave. John Young was very well organized with lots of delegated authority to make decisions. Al Bagley was far more impulsive, hands-on, and personalized than John. It was an extremely different management experience for me, a business school grad, who never had much training on business personalities. Compounding this challenge was the birth of our adopted son who we brought home at 3 days old, followed in 8 months by the birth of our daughter. I had to learn how to be a father as well.

Al Bagley was a personality unto himself, a brilliant man and brilliant engineer, but you had to fit in, and most of his engineers had been with him an extremely long time. There were brilliant engineers, of the Len Cutler variety, the Father of the Cesium Beam frequency standard. You preferably needed to be part of Al's social network, as well as be in his organization, both inside and outside of work. I must admit that I never quite fit that mold. I came from a whole different background, but we did have some wonderful product and market successes during that time. Some of the dramatic contributions that our team made were functionally dramatic frequency counters, Cesium standards, the laser interferometer for micro-inch accuracies, and a powerful computational Fourier analyzer which could transform frequency domain into the time domain, and vice versa. Some of these were brand-new instrument concepts, addressing widely different markets requiring a huge amount of customer and field-engineer training. In some cases, customers didn't even know why they needed such an instrument, but once they and the field engineers got trained in the power of these computational giants, sales rolled in.

That marketing manager job gave me a lot of insight in how to manage different types of people in a technology business. Of course it also gave me a great deal of insight into the digital technologies, which were the specialty of Al's division, while the previous microwave experience was more or less analog, or at least radio frequency. In only a few years, I came back to microwave to take over that marketing manager job, just as the decision was made to spin off the Santa Rosa division. The microwave division had grown to near $100 million annual sales, and experience in those days had shown that divisions around $50+ million annual revenues were closer to an ideal size.

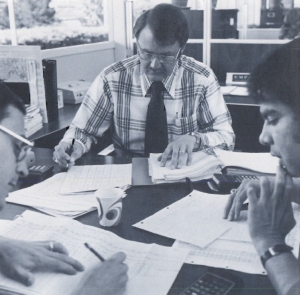

|

In 1972, I returned to the Microwave Division as Marketing Manager. Here I review business plans with Product Mktg Mgr, Ned Barnholt (l), who rose to become CEO of Agilent Technologies in 2000. Mike Cuevas (r) was Power and Noise Product Mgr. |

The Santa Rosa team, headed by Doug Chance, took the fast growing "glamor" product lines of spectrum analysis and network analysis. The remaining microwave division took a new name Stanford Park Division, managed by Rod Carlson, and retained the product lines of signal generators, power and noise figure meters and a large line of microwave measurement components (attenuators, detectors and slotted lines), which were required for setting up microwave measurements. This was a highly profitable business and the products were relatively easy to sell because, when you sold instruments in the many thousands of dollars each, a half dozen small components in the $200 category were items most customers easily included in their purchase.

With several technical advancements in Signal Generators, addressing expanding markets like RF testing, and with innovative marketing efforts directed to the power meters and components, Stanford Park grew very quickly. For several years, it grew faster than the more glamorous product lines at Santa Rosa. Rod's background was R&D, and I had worked closely with him when we managed Spectrum Analyzers together. He gave me considerable latitude to help him manage the division and define the product and market strategies, which greatly helped with my next assignment.

Stanford Park Division had grown again into well over the $100 million range and the decision was made to spin off more the products. Space in the Bldg 4-5-6 area was tight, so that a new microwave spinoff would reduce local space demands. The spinoff took radio frequency generators and modulation testers, in what we considered to be low frequency products, essentially cutting off at 1 GHz, and moved them out to the newly created Spokane Division. We had gotten pretty good at spinoffs and transferring products to other cities, including large teams of people, who brought along their expertise in design and production. At the same time we were growing the Stanford Park product line fast enough on the remaining products so that we didn't have to find job assignments for large numbers of people. In both cases, a reasonable number people were ready and willing to move out of the Bay Area. Not only could they find houses that were much more reasonably priced, but also with a brand-new division there were many more promotional opportunities for these mostly younger and energetic people.

So when 1978 came along and I was offered the job of general manager of Delcon, I was already well equipped with technology and strategic management experience. I felt pretty confident that I could handle most anything that a fast-growing group like Delcon would throw at me. Little did I know!

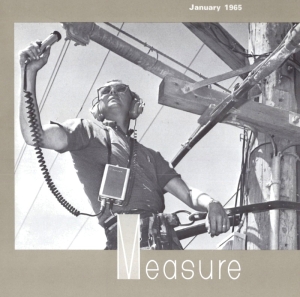

|

This Measure Magazine cover story told of Delcon's "Outside Plant" product line. (Jan, 1965) This ultrasonic detector was able to find miniscule leaks in pressurized cable bundles, up on pole lines. One useful accessory was a parabolic dish which detected the leaks while standing on the ground. Like the audio pickup you see in NFL games. |

The Delcon product line was predominantly what was called the "Outside Plant." This entailed test equipment intended for use on outside telephone pole lines and down in underground conduit installations and manholes. These were rugged little test sets you could hang on your shoulder and take up the pole. The outside plant people are really the roughnecks of the communications business. They are the (mostly) guys that climb poles and go down into dirty and wet manholes. One clever product was a directional microphone that could hear the tiniest ultrasonic noise coming from a pole cable leaking its pressurized gas. The product line was mostly an analog technology, from the copper line years, succeeded by cable multiplex and such.

We had a totally independent and unique sales force that related to these customers, organized to sell almost entirely outside of the HP instrument sales force. Our sales force had some wonderful "down-home" sales characteristics, most of them being self-taught good old boys, yet very smart and very talented, outstanding salesman. But within a button-down sophisticated sales engineering organization like the huge Hewlett-Packard sales force, they were rogues and misfits. When it came time to integrate them into the local sales offices and sales management of HP, this was a bad fit to say the least. This was naturally causing some problems in management, compensation, and such. So the first thing I had to understand was the new culture from a management point of view, as well as to learn about the technology of that sector of telecommunications. Those salesmen were responsible for our growth in that business and we needed to take care of them and help them be successful.

Parenthetically, HP acquired the Delcon Company from a friend of our Steiner family, Alan Simpkins, who was the founder. Alan was also a fraternity brother of my uncle at San Jose State. So we knew him before any of the HP buyout. When Alan founded that company, he had been a serial entrepreneur, and at the time he sold the company, I think his business was doing about $5 million/year.

|

By May, 1978, at 30-something, I was the new Delcon Division Manager.

|

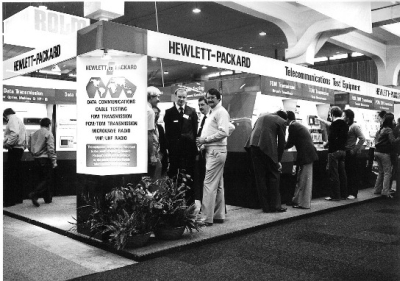

Delcon division was already in the process of designing test equipment for the rapidly increasing technology sector called datacom. They were developing what was probably the world's first protocol analyzer intended for analyzing the digital protocols that managed the data communications. Before that, the earlier form of data transmission was accomplished by interfaces called modems (modulator/demodulator), one on each end of an analog wire line. These products helped telecom companies monitor and manage their earliest data communications systems. As we moved into developing that product line, we were looking at products, markets, and customers that were a much better fit to the Hewlett-Packard instrument sales force.

As we began to roll those new products out to that new market, our growth rate shot through the ceiling. By the 1978 — 79 timeframe, Delcon was growing so fast that we became attractive to HP people who wanted career growth opportunities. This, of course, happened all the time across many HP divisions, but it was happening to us rapidly, and in large volume. Managers in other divisions were calling me to find out why we seemed to be a proselytizing their people. The issue was taking too much management time.

We were also hiring a lot of people into the Bay Area, particularly college grads. They would often stay for a couple of years, then get married, want to buy a house, and would run into the usual Bay Area obstacle of finding enough money to buy one. House prices had been out of reach for young people as long as I can remember. We lost many young, talented, potential managers to divisions outside the Bay Area, to places like Loveland, Colorado Springs and Boise. We couldn't afford the investment of time and effort training them and then losing them, so we finally made the decision to move our division out of Mountain View. Dave Packard himself gave us a virtual carte blanche, telling me that we could choose our new location anywhere in the Western US. So began a search for a new division home.

|

It's pretty hard not to like a work environment like the HP Colorado Springs facility, with a gorgeous view of Pike's Peak and the Western Rockies. |

The "search committee," if you could call it that, was myself and my manufacturing manager, John Shanahan and our wives. We made several inspection trips to cities in the western part of the United States, looking for locations that had the characteristics that HP had previously found were good factory sites. We looked for cities that would provide an attractive place to live and a community that would support an HP corporate presence. We needed a close-by college or university for continuing education. We chose Colorado Springs because we were growing so fast that we didn't have a lot of time to pay attention to building from scratch in a new community. We knew that the HP Colorado Springs oscilloscope division was highly respected in that community. They had been there for almost 20 years and were well integrated into that city. We could leverage those connections and ride their coattails. In addition, with no disrespect to the scope division, their sales had plateaued a bit, and their people were somewhat frustrated with the immediate lack of growth opportunities.

We knew that we could not bring all our 500 employees from Mountain View, nor would all wish to uproot their families and make the move. We also knew that people from the scope division would apply for our job openings. We got permission from the division management to do a certain amount of discrete recruiting, trying to avoid their particularly crucial personnel. The local top managers, John Riggen and John Strathman were very cooperative. They wanted growth opportunities for their people, and at the same time, they wanted to hire some critical experienced people from the outside. We ultimately made the decision to bring about 250 employees from Mountain View, which was a good compromise. We absolutely needed critically experienced people, and yet the corporate expense of employee moves also factored in. Happily, and with a great deal of work by our Personnel team, (including Carol Nakamoto) we helped all of the 300 employees who remained in the Bay Area find HP jobs.

After all that preliminary planning, we decided to make the move starting the spring of 1980. We ended up hiring about 300 people locally, many from the scope division, with some coming from outside companies, and some from college. As it developed, our move turned out to be a positive for the Colorado Springs management, as they didn't have to consider using attrition to compensate for their flat sales projections.

|

I lost all my hair during the chemo treatments, but it all grew back, plus a beard. |

On a more personal note, out of the blue, I was diagnosed in February of 1980 with testicular cancer. I was naive and a little arrogant, as I thought I could begin treatments and still run the division, even with all the chaos of the move. However, the medics made a mistake on the delivery of the second round of chemotherapy drugs. My kidneys shut down from the poison and I nearly died. That mistake took me out of the division for seven months while I received more treatment and regained my strength. Thank God for my Delcon team of John Shanahan, Bob Allen and the other managers, who rallied around me, kept the division going, and made the move happen while I was laid low and struggling to recover.

Another wonderful thing about the Hewlett-Packard culture was that the company backed me up in every possible way, financially, medically and emotionally. My treatments all took place in the Bay Area, so Barbara and I postponed our move to Colorado until July 1981. Most of the division was already there. I've got to say I was very impressed and pleased with how things went without me. It was rewarding to see how the team put it all together. And, I found that the idea, "I'm the only exception to the rule that there is no indispensible man," was again proven false. The early part of the new R&D activity was well underway and manufacturing was pretty much moved by the time we arrived.

My medical episode was a true career interruption for me, as well as a wonderful example of how the company can pull together to replace any key individual at any time. It was just amazing how well the team rallied to continue our plans. What you would consider as a serious disruption of a divisional organization, caused by such a major move and loss of the division manager, just didn't happen for Delcon. During those Colorado-move-transition years, the division continued to grow in the range of 50 to 75% annually. That was just stunning. That kind of growth rate compares to then average HP corporate growth rates of about 15-18% per year. You can imagine the stresses that those large growth rates put onto our manufacturing and HR people. Understand that they have to not only meet all the increasing shipment requirements, but have to hire, train and install new people and production equipment at the same time, for the next year's growth.

We proved that it was possible to maintain those kinds of growth rates, but we certainly learned that you have to be prepared for it. You absolutely have to treat such growth issues as an integral part of your strategic plan. We were running at a fast pace, just to stay even with those growth rates. It took such attention that we didn't have time to get integrated into the other Colorado Springs HP operations very well. As it happened, those same Delcon-move years were at a time when the Colorado Springs Division decided to spin off their logic analysis product line. They had their own significant operational issues to focus on and weren't able to pay much attention to us, either.

Looking back I have to say that all of those obstacles were overcome rather remarkably. We found we could operate independently and yet the three division managers would meet regularly, talk about issues that required attention, and find common resources we could share between the three divisions. Within the Colorado Springs HP complex, the two, and later three local divisions got along very well in terms of sharing common processes. We often used the oscilloscope mainframes, and CRTs in various datacom testers. We used HP keyboard technology, and many of our front panels used specialized keyboard interfaces. We shared many of the common processes like printed circuit board fabrication and loading. We didn't use their custom IC technology, but HP certainly had remarkable capability if you needed it.

With a new home and a new name, Colorado Telecom Division (name was due to telecom still being a significant focus), we began designing a number of products in digital data communications. The number of data protocols in the industry were expanding rapidly and moving from a focus on wide-area network analysis (telephone companies) to local area networks (LAN) analysis. The whole technology of the Internet was beginning to explode, carrying with it brand-newly-invented protocols and longer-range data transmission issues. We were trying to figure out exactly which protocols were going to grow and win in the technology race, and which would be dropped.

I can remember a little vignette of an opportunity called MAP, which stood for manufacturing automation protocol. General Motors was the creator, and very strongly behind this automation standardization software. They were pushing acceptance across multiple industries that would serve not only their own plants, but across the nation in their supplier plants. They envisioned the emerging power of the Internet to make their front-to-back application of MAP a key step in efficiency and quality in design, prototyping and manufacturing. It would standardize between manufacturers and suppliers to communicate everything about a production line, the equipment, the automation, the inventory control and the design processes and standards.

Throughout the world, GM was a leader in this venture and used their might to get HP to accept their initiative, and become the leader in the test and analysis of the required networks. They needed a new protocol analyzer for that program, which would be available to all of the other people that they talked into their standardization program. We did put a fair amount of design effort building some prototype analyzers for GM evaluation. Naturally, it would turn out to be a moving target since this was a brand-new industry-wide venture, and there were plenty of turns, starts and stops as the protocol developed.

This was a very challenging project, and we worked diligently to meet the analysis needs of MAP with a new protocol variation. Ultimately we had several technical shows with GM that were fairly significant displays for their involved personnel. We demonstrated how you set up an automated manufacturing system, and showed the way you'd use Hewlett-Packard's MAP protocol analyzer to troubleshoot the network. We committed several million dollars to that program, but sadly it went belly up. Stunningly, the GM MAP protocol never went anywhere at all, even at GM. It was a huge industrial effort, and I feel sure that it was at least one of the factors that contributed to General Motors' later demise. More importantly, it took a relatively large amount of effort out of our divisional R&D program as well.

We certainly didn't need another stochastic shock at that time. I can't remember the exact date, but I know exactly how I felt. For our division, and all other test and measurement divisions it was a bad move. The top management team of the company decided to merge the instrument sales force with the computer sales force, from the top, down to the local level.

The HP computer sales force was relatively new in those years. Their product line had grown dramatically, as our mid-range computers caught the fancy of businesses. They had been running as a separate sales organization primarily because it was recognized that the sales model was more related to IBM's. Computer sales involved far more top-level contacts, while often in the same customer company, our instrument field engineers were calling on lab and manufacturing engineers and their managers. HP computer sales engineers sold to the IT organization and top executives.

The merger was traumatic. Unfortunately, as the organizational levels and managers were sorted out, the computer sales people got more of the critical management positions. This affected everything for instruments and measurements, because budgets, management attention, and focus soon showed that computers were more important in the HP scheme of things. The result was that the instrument divisions including CTD saw their sales either flatten or decline, due to a lack of attention. I mean it just stopped. CTD was on an aggressive growth trajectory, and as our revenues flattened out abruptly, it was VERY hard to shut down our large production flywheel. The decision at my level was to figure out whether this internal reorganization was going to continue to hurt our CTD sales, or whether it was just going to be a hiccup, that we will be able to get through without too much damage.

Sadly, it turned out that the sales downturn lasted longer than we wanted, and certainly longer than we thought. However, our team decided on a fairly creative approach. While the measurement divisions had to deal as best they could with the new reality, we at CTD reasoned that installed computers required data networks for their very operation, before they could do anything. So we went to the HP computer division managers and their sales counterparts, and pointed out that with our protocol analyzers, HP could provide their customers the capability to design, install, and troubleshoot their computer networks.

We argued that their sales teams really needed to know about our protocol analysis equipment to make their computer networks effective. We were vital, from installation and qualification to maintenance and monitoring, and we would give them a unique competitive weapon. Further, they needed us to actually be part of their selling strategy. We proposed that to make their computer salesman more valuable to their customers, we would be willing to augment the computer sales processes, at the customer's level. Our network and protocol testing equipment and expertise would provide important assurance that the customer operations would be running more smoothly with increased network reliability and quality.

Instrument division sales continued to plateau, but rather quickly our CTD equipment sales picked up again on a nice growth curve. We conceptually wrapped HP's computer networks around our product, and computer sales managers could see the synergy that the CTD products were able to bring to their sales presentations. Their customers recognized those advantages too. Imagine a customer IT manager, choosing between HP and any other computer supplier. Their confidence would significantly increase when they realized that measurement and analysis capability was coming on board to help monitor their networks. Looking back, however, I can still feel the lump in my throat, caused by the sales merger decision at HP high levels. We partially overcame that and were delighted, not just that our sales rebounded, but also that HP's customers were getting a good value for the combination of computers, networks, and protocol test equipment.

Eventually HP management rethought that sales merger and split the sales organizations apart again. At that time, we had to develop, within the instrument sales organization, our own dedicated sales team because our business and customers were so different. We were focused on very different functional people within the customer organizations. Other HP test instruments would sell to design engineers, manufacturing, and field maintenance. The datacom test capability went into the customer's IT operations. We focused on network managers, and installers of data cables throughout their buildings and data terminals coming up on most of the office desks throughout the corporation.

Customers were not only functionally different but they had different kinds of problems. We developed a set of small protocol analyzers to augment portable testing in network sites within a customer plant. Those sold very well because every one of our customers was busy upgrading their networks and their computer software applications, to improve efficiency throughout their companies. We also found that our data analyzers were very valuable for companies who were building the network switching equipment where they needed installation and qualification testing for their customers.

So all in all, our business was back on a rising growth curve and thriving, and that was a very fun and exciting time. We were out in Colorado Springs, in a wonderful physical environment. We were separated from too much corporate oversight, and our business was growing strongly. Our team was dedicated and successful, and was personally committed to our continued divisional growth. That was one of the best exciting times in my career looking back. The most fun, the most challenge, a great group of people, and all the support you could hope to have, from every level of the organization. It was a fulfilling time and one that many of us still remember very fondly.

As our CTD growth exploded, we decided that the original Delcon division products and market were too different from HP's, and that the sales force was never going to be effectively integrated into the Hewlett-Packard sales force. It was like oil and water; they were so different. They were no less talented, just different. They were a bit like wild stallions, not used to being at a desk in an office, not used to daily or weekly reporting to anybody. They were just out there on their own, doing their own thing. They developed incredible relationships with the people that went down manholes and up telephone poles. Managing those unique individuals was a valuable life lesson for me. As a young general manager, I had to learn how to deal with men who were much older, set in their ways, and not used to being managed.

We sadly concluded that it was just a business that HP should not continue to invest in. So we sold the business, lock stock and barrel, in 1983-4. Many of the Delcon sales force went with the business. I remember one or two that made a transition back into the HP instrument sales force, and stayed for quite a long time.

It took considerable effort on the part of my management team to get that product line successfully extricated, but it brought in quite a few million dollars to the HP treasury. In hindsight, it did make sense since the customer fit was not consistent with everything else HP was doing. Our growth in datacom was sufficient to absorb all the division people who wanted to stay.

|

A typical Datacom product, the HP 4955A Protocol Analyzer served research as well as network maintenance, such as computer room performance. |

Hewlett-Packard's own personal computer business was just launching, but our HP PC sales force, again, was really quite separate from the instrument business. My feelings, and those of many other HP general managers, were that there was a fair amount of antipathy between the instrument management and the computer/PC management team. Both were vying for visibility, investment, field presence, etc.

Our R&D group had exceptional advanced knowledge of protocol analyzing. Their expertise on how to do network troubleshooting was a tremendous skill set, built up over many years. The products we rolled out were world-class in functionality and innovation. I can remember a number of times when we went out to talk with customers, we insisted on having our lab's most influential thought leaders included on the technical visit team. Using these experts allowed us to ask for equivalent expert engineers in the customer plant. Once our people would see the customer's network design, they would come back with tremendous insights into the kind of new testing, monitoring and analyzing that was required.

|

This portable HP 4951A Protocol Analyzer went out in the field for network installation, qualification and maintenance. |

The major insights that our engineers brought back showed a deep understanding of the problems that the customer was trying to solve. Yet often, the customer engineer himself couldn't describe the problem, because they didn't realize it was a problem yet. Impressively, our people were able to perceive deeper solutions than those system design engineers. The customer was talking about symptoms and frustrations, and our people were able to take that into a solution design mode. Sometimes there were much deeper problems embedded in superficial frustrations. I found it quite amazing that some of our people's mental processes could bridge those gaps. No doubt it was because our engineers thought in terms of measurements and problem solutions, while the customer engineer was thinking of his data paths and switching and methods to increase data rates and transmission reliability.

After a customer's feedback would get implemented into our new product prototype, we would send the engineer back to those original customer engineers. The customers would be stunned by the insight that the HP team had been able to gather, and by the innovation shown in their solution. It was as if the customer didn't know what he didn't know. I would get phone calls from customer management, wanting to talk about the engineers we sent out. They would say, "We can't believe your HP engineers"! They would state, "If HP can do this, it will revolutionize our business and products". For me, this just confirmed the fact that I had a team of remarkably competent engineers. They not only understood what today's technologies and capabilities were, but they easily extended those into the customer's domain and well into their futures. Our perceptive people would bring a unique analysis perspective, and I saw it happen more than once, so it was not a fluke.

|

The Datacom revolution was typified by our exhibit at the 1979 World Administrative Radio Conference in Geneva, held every 4 years. A massive show, the technical meeting of all nations on the earth, writes global communications rules. |

These were exciting days in network management and network protocol analysis. The industry was exploding because of distributed computing and the early emergence of the Internet. There was so much progress and so much visionary opportunity. The customers in the field had a lot of experience, but much of that experience was directed toward older systems. Many weren't necessarily seeing the potential of new concepts and new technologies, and they weren't facing up to the directions they would have to take to keep their company in the business.

These forces, datacom protocol analyzers, the explosive growth in network management, and the development of the PC business, both inside HP and outside HP, converged on CTD. It was clear to us that we had the capability, and saw the market need, for what we called embedded testing. Traditional HP testing was based on equipment that the customer carried out to do his test job. You might embed that tester in a system rack, but it was still a test function, in a separate box- a test instrument.

This wasn't all that our particular market was looking for. They still needed separate testers in their R&D labs, and in manufacturing. But for most installation, qualification, network uptime maintenance, and ongoing management, what was required was a package of Personal Computer cards with test capability and associated PC software. This test function was to be embedded within the PC housing, which could be called up to run the protocol testing. You could still use the PC as a PC, but if you were a network manager you could connect into the data transmission lines and troubleshoot your network when an alarm would sound. We could not address this, our biggest and fastest-growing market with any other product solution.

We approached this opportunity in two different ways. First, we bought Eon Systems, a small company making embedded network monitoring systems. We thought we could integrate their technology with our own outstanding protocol analysis technology. This would feature an embedded monitoring system for both local area networks and provided data networks. We began to integrate those two technologies into a network monitoring offering sold by our datacom specialist field engineers. We also developed an elegant, sophisticated and inexpensive set of protocol analysis cards and software for any PC. We understood then that we would be first to market with this kind of solution, 2 years ahead of anyone else.

This combined product was a different sell than the normal test equipment sell. As we prepared to introduce the solution of test PC cards and test software within a personal computer, we hit a management wall. I can remember vividly bringing that concept and some examples to a division review. The normal HP corporate oversight process was to have top management make an inspection tour of every division once a year. It involved the top team, usually Dave, Bill and Barney, along with Young, Bill Terry, Bob Brunner and others. This was a time when we reported on our past year's performance and looked forward with our new product strategy and forecast.

When I made the presentation of this new datacom test card and software in a PC solution, I watched the top management jaws drop. John Young, Bill Terry, and my boss, Dick Anderson, all seemed shocked that we would somehow combine testing within a desktop-bound PC. While they looked at it, and gave it quite a bit of thought, you could tell their reaction was, "There is no way we're going to do that." What a downer! I kept pushing and probing, trying to find out the reason for this reaction. The basis of their concern seemed to be that they didn't want their test and measurement field engineers selling PCs. And they didn't want PC people selling instrumentation. Moreover, they didn't want us selling something that could be embedded in a competitive PC.

We knew for sure that whatever this embedded card and software was going to be, it would have to be compatible with everybody's PC. If we had chosen to restrict the compatibility to only the HP PC, we would have missed the majority of the market since HP's market penetration in PCs was very small, probably 10% or less. However, we thought that since our overall solution was so elegant and powerful, even restricting it to HP's PC would still provide a satisfactory solution to our network customers, and a good ROI for HP.

We took this market and product proposal back to management at least a half a dozen times. I kept kicking it upstairs hoping to get them to change their position. I was pushing the fact that this was not a CTD idea but rather it was the solution our customers were demanding, and the potential market was at least as big as CTD's current size. For a market and customer-savvy company like HP, I thought that would work. We needed to offer the total measurement solution to our customers. I was told time and time again, "don't come back, we have listened, and you have our answer, NO!" We were "trapped" into a position where we had no reasonable, intelligent answer to the demands of our customers. I recall working on our division's product/market strategy with CTD's management team, and not being able to find any strategy that would provide continued growth for CTD. We were caught between our clear market's needs, and the intransigent position of our upper management.

We even went so far as to build a clever work-around product, which was a portable personal computer INSIDE a test equipment frame. This product looked like a test instrument, featuring a CRT and a drop-down keyboard, but inside were the regular PC operational equipment and circuits, as well as the add-on protocol analysis cards and software. Since it looked and operated like a keyboard test instrument, we were hoping that this time it would pass the HP management approval. We took it out and talked to customers about that packaging concept, but those customers just laughed at us and wondered why they should buy that kluge? "It's nothing but a PC in an instrument looking case. All I want are your cards and your software, I already have a PC." We already knew that.

So all that extra work, trying to package it inside an instrument looking case, just to get past our management approvals, never worked. By then, we knew that we would never get anything that was directly competitive with the original idea of cards and software, plugging into a standard PC. The depth of the frustration through the CTD team was exceptionally bad.

Very shortly after that unfortunate HP decision, a company named Network General, in the Bay Area, introduced a set of PC cards and test software to be embedded in a PC, precisely what the customers wanted. Our network monitoring business immediately flattened, then declined, and their business shot up through the roof. Within a few short years, their annual sales were $100 million, and we could've had most of that. We had been at least two years ahead of them, and ahead of the market demand, and we had a better solution. It was such a tremendous shame to see us not approved to take advantage of our superior lead in this market. To just fritter away $100 million of revenue with that unfortunate management decision, in the early 1990s, was a pretty serious mistake. We never did know the real reasons for their decision.

Very unfortunately, the effects of my previous cancer treatment problem got intertwined with my general manager job. It turned out that during the lengthy and complex chemotherapy, my kidneys got badly damaged, contributing to my inability to withstand severe stress. I remember working on our division strategy when it became clear to me that we were trapped between the very clear demand of our marketplace and the intransigent position of our upper management. I just could not see a way around this dilemma. Looking back, it was really a sad situation, and I remember it more as a deep disappointment in the way that management treated us. It did not seem to be The HP Way. So, in 1989, I basically crashed, medically.

I was in a medical condition that required I leave my management job, and my beloved division. The doctors warned me that if I didn't leave and reduce the stress, it would kill me. So I left. Had I been stronger physically, I think, looking back, I would've put my job on the line, and announced that I was going to do this and you can fire me if you wish - we're going to go ahead. But I fully admit I just didn't have the strength and energy at that point in time.

After I left the division, a number of subsequent general managers, tried to wrestle with that new product strategy problem. None of them were able to formulate a plan that addressed the market needs but didn't include the imbedded PC cards and software. I occasionally heard from CTD people that they were still struggling to find a way forward, but I couldn't pay that much attention to precisely what was happening, as I had to move on. I had embedded a lot of my life in that division, and I know that the years between 1979 and 1989 were some of the best years of my HP career. We had great products, wonderful people, and dramatic growth rates compared to the rest of Hewlett-Packard. When I took over in 1978, Delcon Division sales were about $7 Million, and when I left, sales were well above $50 Million. I take great satisfaction in my team's accomplishment, in addition to making a worthwhile life for hundreds of employees and their families.

Disappointingly, there has never been a single HP top management person that would ever admit to failing that missed opportunity. Not one. Furthermore, after I left the division, I was pretty much ostracized by the Microwave and Communications Group management. This was particularly hard on me and on my family as we had been work friends for many years. I was faced with the conundrum of whether to stay with HP and find a way to utilize my experience to make a difference, or just leave. I was within 10 years of regular retirement. Either would have been a reasonable career decision. I used some of my recuperation time to work with the management teams of 2 new small companies that HP was buying at that time. Because of my experience of integrating an acquisition into CTD and the teamwork management processes we used, I was able to make a difference, and my writing an integration manual offered good value to HP. I was essentially an internal consultant for the newly acquired companies, and many HP, and acquisition target, managers asked me for advice. I did that for 2 years as I was recouping from my medical setback, and it proved that I could make a valuable contribution to HP in the right situation.

In 1991, Barbara and I decided that I should take a swing at finding an HP opportunity that would involve international experience. We had listened to many CTD engineers we had sent abroad, talk about their experiences and how much they had learned. We decided that it would be a positive thing for us to do the same thing for a couple years. Our first opportunity was Necsy in Padua, Italy, an HP joint venture with the Italian telephone company that wasn't making the expected progress. They were working on distributed telecom monitoring systems for PTT's, including the US telecom companies, but their primary focus was Italtel (the Italian Telephone Company). My telecom and datacom monitoring and measurement experience, as well as my division management experience, proved to be very useful here.

The joint agreement had been put in place by a Telecom Division Manager and a Country Manager, both of whom wanted an Operation on their turf. However, as I soon learned, both sides started with two misconceptions, which lead to unrealistic expectations. HP alleged that they knew how to sell and support complex, distributed telecom systems. Italtel and Necsy said that their system, developed for Italtel, was readily adaptable for the market outside Italy. Neither of these statements was realistic.

The short version of the story is that, after considerable customization of the system, development of a field consulting capability, production of some excellent marketing and service materials, and engaging high-level selling by HP top management, we began to sell some fairly significant systems. Major installations were made in Brazil and Malaysia by skilled HP/Necsy teams. We finally rationalized that it was a reasonably successful business, and the joint venture did work for a while, organizationally attached to QTD, our Scottish telecom division. A lot of work went into the creation of a telecom system sales, service and consulting organization in countries where the market potential looked strong. After 2 years, I concluded I was pretty well done with that project.

We had lived in Padua, Italy, near Venice, and it turned out to be a very formative experience for our family We had our youngest eight-year-old son with us, and Barbara and I were living on the economy, acting like real Italians, and embedding ourselves into the Italian lifestyle. We loved it. We came to learn a great deal about Northern Italy as well as a lot about ourselves. My job challenge had been pretty much resolved, so I told Barbara that I thought it was time to go. Her happy response was, "See you, have a good trip. I'm in love with being in Europe and I don't want to go back to Monument, Colorado."

Serendipity stepped in here, because HP's South Queensferry Division (QTD) had started looking into telecommunications systems control technology. They were experts in the test and monitoring of the RF and microwave parts of the system, and now were looking to move into monitoring the overall system control level, in this case for the 800-pound gorilla in the room, the Bell System SS7 Central Station switching system. QTD was exceptionally qualified in telecommunications technology, having several decades of successful test instrument products. But they had little experience with how to expand their business into the control sector, or into distributed monitoring systems. They needed advice on how to develop the distributed system sales, service and support capability in the HP field sales operation. Sound familiar? Again, these were new customer functions within an existing HP sales organization.

I had just spent two years in Italy working on, and solving, virtually that same problem, just with a slightly different product. Knowing that I was now just a few years away from retirement, I just said what the heck, let's go help QTD resolve their problem. This involved moving the family to Edinburgh, Scotland, and we spent another two years there in a very satisfying role. We managed the sales integrations required with both the US and International field management. This involved working with the field to set up special new customer consulting capabilities, to work with the highest level of customer network management.

This was not a trivial sales activity, because in most of these top-level selling jobs you have to be ready to bring in the ultimate Hewlett-Packard salesman, in our case CEO John Young. When you get two CEOs together for the final pitch, good things can happen, but you have to carefully prepare everyone, and it takes clear planning to get all the facts straight. Hewlett-Packard was already one of the world's outstanding IT and distributed computers and network companies, and this meant that our own corporate personnel had a good reputation and applicable knowledge. John Young was an exceptional salesman, beginning with his microwave days, and he was seen as a very credible manager by our customer's top management. Often, we would bring in some of our HP internal IT managers to describe our own system strategies. We went to China to sell the telecom monitoring system, and we were able to see the Minister of Communications who was among the top 10 managers in China. Dave Packard paved our way for this.

We also had to establish new repair and customer support activities, where our support personnel would do house calls into the customer plants and remote sites, at all hours of the day, to troubleshoot their major monitoring systems. At that time, there were other HP Test and Measurement entities that were doing on-site customer support of systems for Board Test, etc. Telecom monitoring systems, however, required a more sophisticated plan, which was considerably different than our usual instrument repair and calibration services. With instruments, you bring or send your faulty equipment into our repair facility. Having field support technicians and engineers available to go inside customer plants was not new for companies like IBM computers, or even HP computers for that matter. But bringing this new process into an instrument service force required new thinking. Yet it was the crucial step in making those new systems successful at QTD, as well as at Nexcy.

Finally, we had to hire and create a new true consulting capability. Our customers needed to be trained on the theory and technology of network monitoring in general, as well as the capability and techniques of our monitoring system. This consulting was provided during the initial sales effort, and continued through the installation, and into the operation of the system. It initially had to be priced into the system quote, but afterward sold as a service. This was a whole new capability and process for the field.

The Test and Measurement Group managers recognized that what I had learned could be very valuable to all their system solutions. I was ready to retire, but agreed to stay ¾ time for ¾ pay, and work for Larry Potter, VP of Marketing, and with his 2 key support managers, Reed Hilliard and George Sparks. People knew I was retiring, and did not want anything else but to see them be successful. This gave me considerable credibility and freedom to consult in several product divisions, and with the support divisions. Some of the relationships I developed during that time have lasted long after retirement. I helped them recognize a new measurement systems support reality for their divisions. It was that system support required consulting and mobile experts that could move into a customer company, and resolve their system and network quandaries. My experience in understanding customer priorities was a big help in making our own HP support management knowledgeable of the directions they would have to move.

Again, on a more personal note, our time in Edinburgh, Scotland, was wonderful. My mother was Scottish, so we dove into her clan and dressed the part. We have lifelong friends who still live there, whom we visit occasionally, and we have been invited to the weddings of their children. This experience, and the one in Italy, transformed our lives, giving us a much richer understanding of our America and the extraordinary experiment it is.

|

Regular all-division meetings on the factory floor kept people up to date

on our division's situation. Often there was a celebration, or recognition of someone's special contribution. |

I actually stopped working for Hewlett-Packard in July 1997. But like most everyone at that time, I had so much accumulated vacation and medical leave, at the rate of six weeks per year, that my actual retirement date was January 1998. That gave me a combined 33+ years with HP. I've got to say those years were a wonderful roller coaster ride. I never imagined, as a brand-new MBA in 1965, facing a future at Hewlett-Packard, a business life that would yield so much satisfaction. More than once during those years, people came looking from the outside, to hire me away from HP. They offered challenging jobs with significant salaries and options, as well as impressive titles like VP or Director. Although I was always flattered, I realized that some of those offers were partly driven by the exceptional visibility of HP's excellent management image. Many of these companies were in Santa Clara Valley, so they were aware of the dominance of HP management style, and of its success.

I can remember once driving along the brand-new Interstate 280, behind Palo Alto, and talking with Barbara as we considered the pros and cons of leaving HP for an attractive offer. We were jokingly spending the 100% increase offered in salary, however, we concluded that it just wasn't what we wanted to do. As much as anything else, it was the HP culture that would always hold my loyalty, and Barbara would agree. She could see that I was so challenged and happy in my work, and proud of what our company stood for. We were aware that a number of the other companies had work cultures that were disruptive and disrespectful. I reasoned that if I could go in as a CEO I might have a chance to change some of those cultures. But to enter a new position as a VP or director, I would be at the mercy of their culture that probably would not change. I knew people who had attempted that, and were not able to influence the new culture dramatically.

HP work culture was like no other that I was aware of. You could trust people to do as they promised, and to do it as well as they could. I remember John Doyle, who was one of the excellent early managers at HP, and the Microwave Manufacturing manager under John Young. He was also one of the early managers sent over to the Bedford, UK operation, to get production started in England. John later left HP, and then came back. I talked to him about why he was making the move before he left, and I talked to him after he came back. He told me the following story that just epitomized his reasoning for returning.

He had a secretary in his new company, and would ask her to do some task you would expect of an administrative assistant. But either she wouldn't do it, or she wouldn't do it well, or she would do it late. Having been familiar with HP's secretarial pool, he kept thinking that he could bring her up to the same level as his HP Administrative Assistants who met his needs and his internal standards. It seemed logical that other work environments could equal those of similar work at HP. Yet, he could never get her to adapt to his instructions. It was just one little experience that defined the HR differences, which were not all at obvious from the outside. You couldn't rely on people to do what they said they were going to do. Or to do it on time or do it the best way they could, and be collaborative about it.

|

One of the very best HP traditions was the summer picnic. All the managers turn out to serve New York steaks, beans and butter-dipped corn on the cob. Some, like me, even agreed to star in the Dunk Al water tank event (r), and that water was COLD. |

Looking back at our CTD move, because of my cancer, I arrived in Colorado Springs almost a year after the division move started. It was clear then that there were some cultural differences between the people we brought from California, those transferring from the Colorado Springs Divisions, and significant differences with people hired from the outside. We needed help in creating a true teamwork culture, including some hard work on communications and team building. I decided to look for professional advice, and hired a young woman professor, who had just gotten her PhD in organizational communications. Her name was Pamela Shockley. She worked wonders on her assigned project. I was very impressed with her ability to reach into people's psyche and habits. This involved improved formal communications, as well as opening up more trust between the different functional groups within the division. She helped us a great deal. Pam grew to become Chancellor of the University of Colorado at Colorado Springs for at least the past 10 years, responsible for dramatic growth in students (>11K), faculty, and facilities — faster than any other campus in Colorado. We have remained close, and I have been on her Advisory Board throughout that time.