HP Memories

This chapter, for me, is the most interesting, because it is the main reason I wrote the book. It seems to me that as HP, and probably all companies grow large, the policies and procedures that must be implemented, to stay organized, begin to stifle creativity, and bog down the fine personal initiative of its people. Hiring becomes more "safe;" decisions become more conservative. People probably become more homogeneous.

I'm going to introduce you to some characters, who were far from homogeneous. Starting with Bill and Dave themselves, we will find a human side that cries out to be replicated in all our new people. I want all our new people to understand that they can break through the "safe" operating mode and use their creativity, challenge the bureaucratic processes, and keep the company loose and interesting and fun to work for.

You will see that most of these people are not the most "important" ones at HP, but they were surely some of the most interesting. Further, there were a lot of crucial contributors, I don't list, who were in other divisions or cities or countries, since I didn't have much interaction with them. There were hundreds of them. I have heard many interesting stories of other people, but I have tried to mostly only describe people and situations that I was close to, or at most second-hand. Other than Dave and Bill, these names are in no particular order of importance or age.

Bill was a tinkerer. He loved to spend his time in the Lab with Barney Oliver, after Barney returned from his work at Bell Labs in the 1950's. They were a perfect match, Barney with IQ of 180, and Hewlett with the technical curiosity of an Einstein, yet the business sense to see technology solutions and products.

It was not unusual to find Bill in the plant on weekends. Perhaps he was working on an antenna for the fly-in airstrip, on the ranch, he and Dave owned in South San Jose. On one weekend evening, he was working on a radio antenna, and needed some parts from Lab Stock. It was the late 1960's and division management was on a cost saving initiative, which came and went, in cycles. Some manager or bean-counter decided that open lab stock was a license to steal, so the lab stockroom door had a padlock on it, after working hours and weekends.

Bill called a guard to open the tool room door in the facilities department, to bring him a bolt cutter tool. He cut off the padlock, got his parts, and left a note on the stock room door to the effect, "Don't ever lock this door again," signed Bill Hewlett. Guess how many years that that note prevented lab stock doors from being locked? Such action gets around-everywhere!

Bill's attitude was that we hire expensive design engineers, to create new products. At the same time, many have hobbies, such as ham radio or audio system design, which teach them new design tricks, useful in their regular HP job. Bill was willing to accommodate the use of HP parts, from the lab stock, to assist the engineers in their off-duty hobbies.

Marc Saunders tells of the Saturday afternoon, when he was shopping at the Menlo Park, CA, Hardware. He noticed Bill Hewlett, by a counter of wood screws, introduced himself, since they had met at some management review. He asked if Bill were doing some home project for the day? Bill nodded yes, but in an impatient voice complained, "Isn't this ridiculous, I just need 3 wood screws, but the way these are packaged, I've got to buy 24 of them." This, at a time when Bill's wealth was about $1 billion.

Bill promulgated another informal process for engineers, called the G-Job, or "government work." The idea was that every engineer was to be allowed to spend up to 10% of their paid work time, on product concepts, that might result in a saleable product, not in the official plan. This was to include necessary model shop time for building materials, or purchased parts if needed.

Probably the biggest and best example of a G-job was Barney Oliver's exceptional audio amplifier for superior home stereo use. Barney's design for audio amplification had unbelievably low noise, hum and distortion, which I will not attempt to quote numbers for, since I never did understand audio amplification principles. A regular production run was created, orders were written for panels and pre-punched sheet metal, plus unloaded printed circuit boards. The whole assembly was packaged as a kit, which any employee could buy, and assemble themselves. I think it ran to a second production run too, because of the word of mouth.

Another under the table project resulted in an HP product, and one that was quite unique. Frank Waterfall, of the Crossley Associates sales office in Chicago, mentioned informally to Barney, probably over a drink, that what many circuit engineers really need on their bench, was a way to measure small dc currents going down a wire, without having to cut the wire, and alligator-clip it to a milliammeter. Barney put someone on the project, and came up with the HP 428A probing ammeter. One just opened the probe, which separated a magnetic circuit, and clamped it over the wire to measure current, a very convenient and popular instrument. The meter sensed the magnetic field caused by current in the wire, using a "flux-gate" principle.

This was just the time in history, when the banking industry was creating the magnetic ink characters on the bottom of regular checks. They did this so that high-speed, computerized machines could retrieve the bank number and bank account, plus the dollar amount, added with keystrokes, from the written check document. But a problem developed in the check printing companies, because the consistency of the magnetic ink printout was often inadequate, and the check numbers wouldn't read accurately on later processing. So one of the lab engineers, on his own time, took the clip-on probe, opened up the clamshells, and made a sensor which could detect the quality of the printed magnetic ink properties in the printing plant. It sold a large number, although it was later supplanted with simpler dynamic machines, which read numbers on the fly.

An interesting education for me, was Bill's idea of personal and business relations. It happened in the early 60's, during the period when Tektronix fired of all their independent reps. For a time, before HP entered the scope business, many of our independent reps also handled Tektronix. When HP decided that they needed company-owned distribution, Bill and Dave made the decision to make offers to buy all of the U.S. rep companies.

So HP bought 11 of the 13 reps, instead of releasing them like Tek did. Two declined. Sometime after, I was talking informally with Bill at a management meeting at Rickey's in the mid-1960's. Although I thought I knew the answer, I asked him why HP had spent something like $10-15 million dollars for this move? I noted to Bill that Tektronix hadn't spent a penny, but simply released their reps, one at a time, over a couple of years, to smooth the transition, and set up their own company sales offices.

His answer was, "Goddammit, Minck, you just don't understand the situation. These reps are all personal friends. For a decade, we did business with them, on a handshake. We owe them most of our success, in building our industry and the company, and there was no way we were going to just fire them, one at a time." So there, John Minck! Bill and Dave regarded personal friendships with honor and integrity, and, not incidentally, backed it up with a lot of money.

One evening, I was working late in Building 3, so it must have been in the early 1960's, and I guess it must have been about 10:00 pm. At the far end of the building, I could hear the old noisy 910 Xerox machine clacking away. I would get up from my desk, once in a while, to get a cup of coffee, and a young man was intent on building a rather large stack of copies. It grew in time to be at least several stacks, each a foot high. When I passed going to the restroom, I could see it was sheet music.

I finally put on my corporate hat, and approached him and said, "I'm sure the company doesn't mind people doing some personal copying, but don't you think this is going a little beyond that?" He replied, "I understand, but my dad said it would be OK." Although it was none of my business, I said, "And, who is your Dad?" "Bill Hewlett." Oh. OKaaayyy. I think it was son, Walter.

There is a followup to this story this year 2011. I had sent a letter to Walter Hewlett, to send along a written copy of the Tribute I wrote about his father, on the 10 th anniversary of Bill's death in 2001. Marc Mislanghe had asked me to write it for his HP Memories website because I knew Bill somewhat. So I also sent Walter that URL. He kindly answered my letter by telling me that he enjoyed reading several of the memoirs, and was finding that in his later years now, he was finding more appreciation of the work culture that his Dad was instrumental in creating.

In the same letter, he read about my anecdote in the Hewlett profile in my memoir, where I told of one of Hewlett's sons standing at the old Xerox in the 1970s for an hour, copying a high stack of sheet music. He admitted that it was him. And he remembered me coming along to ask him whether he had permission. It turned out that he was quite a musician in his Palo Alto High School days, and their music teacher was a renowned music expert, Julius Schucat, who had accumulated a large archive of sheet music for those years. Schucat had offered Walter the chance to copy a lot of it for his later use.

Most of us have read of the many innovations that Bill and Dave instituted for their employees. In the early years, when one employee had a catastrophic medical episode, they realized that their company should provide for group medical benefits, long before American industry came to embrace such benefits.

But Bill was also observant about individual situations too. I was told about the early publications department, where Mary Hurt worked as a "repro-typist." Later, she and the other graphics people transferred into my Marketing Group in the Microwave Division. It seems that Mary's marriage was such that she was raising 3 or 4 kids all by herself, and this was causing serious time constraints on her being home to watch the kids and being at HP to do her graphics work. Bill found out about the situation, and told the managers to make whatever arrangements were necessary, so that Mary could work at home on her special company type-setter typewriter, until such time that the kids were old enough to help in the family's responsibilities. Mary never forgot that exceptional act of humanity, and told us about it until she died decades later of cancer.

Dave and Bill were well known for introducing two management processes, The HP Way and Management by Objective. But they also promulgated another process that was even more important in some ways, it was called the Open Door Policy. This simply stated that when there was an important matter that your own management wouldn't listen to or accept, you had a right to walk into any higher-level manager in the company to make your case. The door was open. Bill had a "feel" for what was right for common-sense management principles, so it wouldn't surprise me if he was the source of this idea.

In actuality, both Dave and Bill recognized that such a permissive policy might be abused by an endless complainer. So they specified that the employee had to first exhaust their appeals at the first and second level of management. This rather remarkable policy had two important effects; 1) It gave a sense of empowerment to each employee and made you feel like top management was with you, and 2) It proclaimed a not-so-subtle warning to mid-level managers that their actions were reviewable at the highest level.

Here is one specific example I am aware of. One of my friends had begun reporting to a new manager who had been hired in from Ampex Corporation, presumably for some of his tape recorder systems expertise. 1970 was not a good year for high-tech, HP fell into a bit of a recession, and the word came down from top management to trim 10% off operating costs.

My friend got called into his boss's office and was told that he was fired. That was the Ampex way of controlling costs, hire and fire as the profits allowed. This kind of employee treatment was unheard of at HP. Luckily my friend didn't take it lying down, but using HP's "Open Door" policy, he marched up to Bldg 3U, and told Bill what had happened. Bill rescinded the firing order on the spot. The word got back quickly to the Ampex guy's division manager, since it also appeared that my friend's performance reviews might have been doctored to justify the layoff. I think HE might have been the one let go. Soon after, this memo was sent to all HP management:

July 16, 1970 From: Bill Hewlett SUBJECT: Evaluations & Terminations An increasing number of cases are coming to my attention in which employees are being terminated with little or no warning that their performance has been unsatisfactory. In some cases, evaluations have been glowing up to the time that an individual is released. Signed: Bill H.

|

That 1970's business recession was also the time that Bill came up with his famous plan to deal with lowered revenues and production overcapacity. It was what John Doyle termed the 9-day fortnight. Hewlett reasoned that the nation's business would turn up in a year or so, and that HP could not afford to lose creative people, skilled production staff, and loyal employees who weren't themselves responsible for the downturn in business.

Hewlett observed that, "Usually in business, it is the little guy on the line who takes it in the chin, while management and higher-ups stay at work. It is only right that everyone share in the pain, up and down the line." He insisted that all employees take off every other Friday without pay, and this action was widely praised, not just within our employee ranks but got national publicity as a way to deal with downturns.

It was interesting that this was the recession period when Dave Packard was off in the Pentagon as Deputy Secretary of Defense. Hewlett made this important decision on his own, in conjunction with Noel Eldred and Ralph Lee whom he had brought into a corporate office triumvirate. The employee loyalty that resulted from this common sense plan was wonderful to see. Many employees actually came in to work on those Fridays, even though the production lines were shut down. Sales forces, of course, maintained their full schedule since increasing sales was the main point to get back to full employment. Factory marketing ran with skeleton staffs. In about one year, sales picked up and we all went back to work.

Fortuitously, the HP-35 hand calculator was introduced in 1972, and with its huge profitability, it single-handedly pulled the company out of trouble more quickly than the basic business recovery.

Finally, it is almost never mentioned that Bill Hewlett, in spite of his love of the technical side of HP, took over as CEO and Chairman of HP in 1969, when Dave Packard was appointed to Deputy Secretary of Defense, at the Pentagon. Bill formed an executive committee, consisting of himself, Noel Eldred and Ralph Lee (Porter had died), and grew the company from $326 to over $479 million. This was an average of HP's usual 15% per year, for those 3.5 years, without the benefit of Dave's presence, and in the face of a persistent business recession.

This story came to me in 2009, when Ken Chalfant of Colorado Springs, CO, contacted Ken Kuhn in Birmingham, AL, to find if he might have a spare HP 120B scope bezel. Ken Kuhn's name comes up in this Narrative several times, because he is a big HP booster, and further, maintains a basement and garage full of more than 400 vintage HP instruments. And he never worked for HP. He passed along Chalfant's charming interaction with Bill Hewlett.

|

Bills' gift to a teenager |

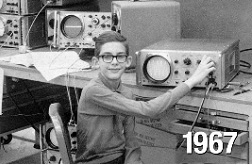

Chalfant reminisces: "My story regarding Hewlett Packard starts in 1967 when I was a junior high school student (age 13). I was already totally focused on electronics, owned an EICO VTVM and was trying to save up money to by a kit form oscilloscope from HeathKit when my science class went on a tour of the local HP plant here in Colorado Springs, CO.

Wall to wall, as far as I could see was test equipment and oscilloscopes so far beyond fantastic that I probably almost had a seizure! When I got home I called out to the plant and asked if they had any used scopes for sale. "We don't sell our used equipment." came the answer. "How much is your least expensive scope in kit form?" I asked. "We put all our equipment together - we don't offer kit form." was the reply, followed by "Would you like a catalog?"

My mom took me out to the plant and I met the local marketing manager that I had talked to on the telephone and he gave me a copy of their catalog. OH MY! What a catalog! It was nearly an inch thick of glossy pages stitch hard-bound into a beautiful book. I took it everywhere and wore it out! It was not only filled with their equipment, but a great deal of information on how their equipment worked and how to apply it. That catalog was my first electronics instrumentation text book. I still have that exact copy and I have also bought a pristine copy for my library.

Well I wasn't finished - I was not ready to give up on getting an HP scope so I wrote Mr. Hewlett a letter and asked him if I could buy a used one. Well to keep a long story somewhat shorter - Mr. Hewlett gave me a 120B scope!

|

Now an engineer and a customer

|

Forty years - to the month - later - Agilent rediscovered the story of what Mr. Hewlett had done for me and they invited me out to the Colorado factory as a guest speaker to talk about Mr. Hewlett and the "good old" HP days - even though I have never worked for HP. Then they did it again - they gave me another scope.

Its amazing that a man I never met and a company I never worked for have had such a profound and positive impact on my life! Mr. Hewlett, followed by several engineers at the Colorado Springs plant, helped me so much when I was just a kid! Then after telling "my" story and helping them remember how fantastic Mr. Hewlett and HP really were they basically "framed" my life by giving me another scope.

Of course, I'm completely biased, but I doubt there will ever be two more significant and honorable business people then Mr. Hewlett and Mr. Packard. I don't think anyone will ever build a company that will contribute as much in technical terms and so much more in human terms than did Mr. Hewlett and Mr. Packard. Agilent still makes fantastic equipment and there are many wonderful, caring, involved people working there, but Agilent is not - and never will be - Hewlett Packard."

Dave was well-known for being the "business-oriented" partner, while Bill assumed the more technical role. With his 6-4 stature, and Stanford football player physique, he always dominated any meeting or gathering, whether a speech to the investment analysts on Wall Street, or while standing at the coffee pot. Most everyone is familiar with his management style, as described in his book, The HP Way. I wanted to mention several specific interactions I had with him, personally, and which will help you understand the humanity of the man.

After President Richard Nixon "opened up" the People's Republic of China, Bill Hewlett and Dave Packard both visited China in the several years thereafter. During Packard's visit, he met with the Fourth Minister of Machine Building, which was similar to the Russian organizational hierarchy. The Fourth Minister was the national official responsible for all electronic and communications activities in their country.

The technology situation in the PRC was serious, because the previous "Cultural Revolution," permitted by Chairman Mao, had decimated their academic and technical community. It had resulted in 2-3 million deaths in the purge of intellectuals. By the time Packard visited, the country was trying desperately to rebuild their technical infrastructure, a monumental effort. As a result, Packard agreed to host 20 young engineers at HP for one year, to have them work alongside our production people, to gain a knowledge of current state-of-the-art electronics production. Dave's objective was clearly to plant our HP flag in China for future business opportunities.

Packard called V.P. Bill Terry, to tell him to arrange things. Bill appointed me as the Test & Measurement Organization host, to be ready to host 8 of the 20 engineers. So I set up the planning for those engineers to go through some initial measurements training, and then prepared the one-year "dance card" with schedules of each engineer for their year here. This plan would take them through the many different production functions, printed circuit production, production control, fabrication, etc, for a full year.

Since I had been given virtually zero detail, I called Dave to ask if I could come over and review the plan. In his office, after he had taken a few minutes to read the summary, I asked if it looked all right to him, based on his understanding with the Fourth Minister? He looked at me, with a sheepish smile and said, "You know, John, the night I arranged this plan with the Fourth Minister, we were at a long ceremonial dinner, and frankly, we had had quite a few toasts, and a lot to drink. So the specific issues of the engineer visitors are not real clear to me today. However, this looks like a fine plan. Go with it." To me, this confirmed the total honesty of the man.

A funny incident happened when the Chinese engineers arrived about a year later. Our first formal process was a 12-week measurement training course, to acquaint them with HP's products and services. Actually it was the same measurement training course which was given to all new HP field sales engineers. It was about Christmas time, and the training was taking place in Bldg 18, at the corner of Page Mill Rd and Foothill Expressway, in a building shared with the HP TV studio.

Since the Chinese group was about 20, we set up a special class for them alone. I was observing the training orientation, when suddenly I was called out of the room, to face several U.S. Secret Service agents. It seems that U.S. Secretary of State, George Schultz, who had his home on the Stanford University grounds, was home for the holidays. He decided that morning to visit his son, who happened to work at the HP TV studio in the same building. When the Secret Service heard, during their quiet visit, that there were "Red Communist" Chinese personnel on the same site, I guess they really spooked out.

They had gone into a protective mode for Schultz, then told me that everyone in the room would have to remain there for an hour. I had the temerity to ask if we could first offer the students the chance to go to the bathroom, and they relented. But I could never tell those students just what happened.

I was profoundly impressed with those young Chinese engineers. Since they had been selected by a nationwide process, they were given the travelling status of "Diplomat." This was not a trivial distinction, since their ordinary in-country monthly wage was $30 U.S. HP had agreed to pay them a salary of $1500 per month, which was our going rate for new-hire engineers, and under their country's diplomat provision, they were permitted to keep it all. We organized a housing program, whereby they lived, two to a room, at the Flamingo Motel, on El Camino, where our visiting FEs normally stayed. We also bought them all bicycles to get to work on the hill.

Imagine my surprise, a month later, when I visited their motel, and found out that most of them had moved out, and found other less-expensive apartments, and now were living 6 to an apartment. They were serious about saving money. But it is what they did with the saved money that impressed me.

Since most of them had been voted in by their local factory personnel council, they felt a true obligation to their factory. For example, as they learned about our HP environment testing program, they began to request for me to order them temperature testing equipment and systems, from various sales catalogs. By that time, HP's pre-production testing had revealed that every product, ready for production, would get a full series of high temperature tests. To assure that their factories would have the latest in test procedures, they bought the same temperature-logging gear HP used.

They also bought numerous TV sets, calculators and personal computers, all of which were going to go back, to be shared with the people in their factories. On one occasion, I used an HP truck to carry all their boxes to the Port of Oakland, to load into a transport container. I think there were 150 boxes, all of which had to have customs documentation, and shipping arrangements. Our shipping people were of great assistance, in guiding them on the least expensive mode.

The specific State Department program authorization we worked under was unusual. The project fell under the U.S. Technology Transfer laws, with some REALLY serious penalties hanging over any mistakes. The paperwork we furnished to get approval for the year-long program, also was interesting. These alien engineers were allowed to work anywhere in our shops, read any documentation, actually order instruction manuals for HP equipment, and other printed industrial materials, commercially available. But the one thing they could NOT do, was to talk personally with any of our R&D engineers. It seemed a quaint rule, regarding the nation's technology transfer restrictions. Further, we had an intensive briefing with the FBI, so that we knew exactly what to do in case any one engineer asked for political asylum. Not one of the 20 ever did.

As it developed, it was a very successful program, and in later years, I heard from more than one of our HP sales people in China, that several of the early trainees had asked about me, and were ordering HP products. I believe that several actually came to work for HP China in later years, and certainly they all became good HP equipment customers.

George Stanley was closely involved in the HP entry back into the People's Republic of China, and relates his remembrances: "Bob Brunner always like to travel to unusual places. So right after Nixon opened up China, Bob was about the first person to figure a way to go there. While in China, he looked up an old college classmate, who was fairly high up in the Chinese government and asked him, "How would China like to have a team of HP engineers come to China and teach you the latest in western measurement techniques."

"The Chinese manager jumped at the chance. Bob had cleared this with H and P and Doolittle before he left. When Bob came back he asked me to put together the technical program. Lee Ting handled the political/business coordination, and the team consisted of Art Fong, Dave Widman, two guys from Ft. Collins, and Bob Frankenberg from the computer side. I think there were a few others."

"I had Don Hawke organize and ship all the equipment. We worked closely with the U.S. State Department. We were in China for four weeks in June of 1979. The first week was used to unpack the equipment, set up and work with our translators. A month before leaving the U.S. we had to send the complete text of our technical talks. I had HP-IB for four days, but remember this is two days of material because of the translations."

"All in all there were probably about 150 Chinese who attended. my class was led by a Red Guard radical who marched his class in, told them to sit, told me to start, and would stop me periodically and say, 'we take break now.' He would march the class out and back, etc"

"We found out that we could take our wives if we paid the air fare. The hotel costs were the same for two as for one so all brought their wives and that sets up a story. The Chinese set up daily tours for the wives with special guides... no charge. The reason was because the guides were all top Chinese Government translators who wanted to polish up their English. One day my wife was asked, "what does, 'in the same ballpark mean?'"

"We were in the Machine Pak building over near the Zoo, but stayed in the Grand Hotel near the Forbidden City. Engineers came from all over China by train and for some it was a two-day trip. Only one came by plane, and he was a EE Prof. from SW China. I got to know him fairly well as later he came to the U.S. on a trip."

"We always had handlers and were escorted everywhere even after the formal session ended. We were allowed to visit other cities in China, but we would be taken to the plane and then met at the next stop. We worked our way south, eventually exiting into Hong Kong."

"Brunner told me my second objective was to get the name/address of every engineer who attended so we could put them on the HP Journal mailing list. I did. There were many interesting events. One was the whole country was studying English. There were two radio programs: The Chinese ran one and the Voice of America ran the other one. Being white, we stood out so we were often approached to correct their English homework."

"The EE Prof once told me people used to study Russian but everyone had given that up and were now all doing English. The VOA broadcast in 'Special English', which was a printed list of about 500 words that were spoken extra slowly. I tried to get the list of Special English words to give to the Divisions to use when giving seminars abroad, but VOA told me I would have to have someone outside the U.S. order it. I didn't follow up."

"John Young managed to show up at the very end as he came over from a meeting in Malaysia. There were nightly dinners with the Chinese and they always tried to get us drunk with their clear fire-water. Somehow we all survived even though we had to rewire the Machine Pak Building to get enough power to run our equipment."

"As a result of our visit the Chinese published the HP-IB info and a test I used in a technical journal. This was in Chinese and I used it (in Chinese) when I gave the Chinese engineers of the Packard invitation their final exam. I think they were surprised that part of their exam was in Chinese. All this led to a Chinese invitation to H and P to visit China and you know the rest."

By the way, Packard resigned from his Pentagon job well before the Watergate political scandal broke under Nixon. In a real ironic twist of fate, Packard and his wife lived at the Watergate complex during his tour at the Pentagon. One wonders if he somehow had found out about the bad things going on across the Potomac? It was also at approximately that time, that John Young began his long rise to fame, and moved up to Electronic Group V.P., from his leadership of the Microwave Division.

At one of the 1960's management reviews at Rickey's Hyatt House in Palo Alto, it had been a long day of presentations. I happened upon Dave, standing at the bar, for the usual after-meeting libation. He would usually ask how one's work was going, as a sort of generic comment.

As it happened, about two days before, I had had to tell a long-term microwave application engineer, who reported to me, that his work was not adequate. This was even after we had informed him of the inadequacy and worked with him for a full year to solve his problem. I mentioned to Dave that the act of actually telling an employee, that he would have to leave HP, was one of the hardest things I had ever had to do.

Now, all of us employees had an overall impression of Dave Packard as a "tough-minded" manager, because we had all heard of his statement, "If you can't do the job, we'll find someone who can." So I figured with my story, he would probably understand my personal distress. He surprised me with his response, "Well, John, it may interest you to know that I have only personally fired 2 employees in my time. And those events were two of the hardest things I have done, too." That comment only increased my admiration for the human Dave Packard. I inferred afterward, that he probably just told others to tell people they had to go.

In 1969, Packard was recruited by Melvin Laird, who was the political transition manager, tasked to find high level appointees to the Nixon administration. Laird himself was appointed to be Secretary of Defense. Packard agreed to become Deputy Secretary of Defense, as long as Mr. Laird agreed to be the "Mr. Outside, who would deal with Congress and the public. Dave would be "Mr. Inside," and would deal with operations and procurement. As he told his employees, he had always felt that he owed his country some national service time, because he stayed and managed HP on the home front during WWII, while Bill served in the U.S. Army Signal Corps.

During the years Dave was running the inside operations of the Pentagon, we would often have military visitors who were coming to HP for contract negotiations. They told impressive stories of Dave's pragmatism, in managing a huge agency and huge procurement budget amounts. Packard was responsible for the Pentagon's "Fly before Buy" contracting concept, which he introduced to avoid the excessive budget overruns. These were caused in previous administrations, by going into production before a weapons system had all the operational and technical kinks worked out.

In the late 1970's, one of our newly-recruited field engineers (Jim) told me of an interaction he had had with Dave Packard in Vietnam. He was a young fighter pilot, and USAF Captain, during an inspection trip Packard was making to the military bases there. Packard had specifically asked the military commander to bring about 25 of the pilots who were carrying out the missions into a conference room. So Jim and the others were there in the conference room, sitting at attention, while around the walls were several dozen higher-ranking brass.

As Packard came in, he noticed the large array of colonels and other high ranks, and asked, "I thought I was quite specific, that I only wanted to talk with the men doing the flying." One ranking officer noted that they felt that it was important for them to attend, because then they would know what issues to take seriously. Dave reiterated that he was serious in his request, and that all of them should leave, which they did, a little humiliated in front of their troops.

Dave then took off his suit coat, rolled up his long-sleeved white shirt, and draped himself on a chair. He proceeded to spend about 2 hours in the meeting, getting to understand the true tactical situation. It was the HP "open door" policy, sort of in reverse. Jim decided that day, that if he survived, he would do all he could to work for HP in the future, and later he did join the HP field sales force.

Dick Rucker recalls that he and his wife Claudia ran into Packard one early Sunday morning at the National Zoo in Washington. Dave was scheduled to appear before a Congressional hearing on his upcoming Pentagon appointment on Monday, and he was there, "apparently, just to relax and gather his thoughts."

"We ran into him in the large bird aviary -- it is a large screened-in area but otherwise open to the elements, and it was home to a California condor, a couple of American Eagles, and a few other large birds. He was standing there, with his hands in his pockets, looking up, admiring one of them."

"I walked over and introduced Claudia and myself, and told him we were both former HP employees who had met and married while there. He chatted with us for a few minutes, then we wished him well, and left him alone with his thoughts." "My particular memory is of him standing there, looking up, just as I realized who this tall, very distinguished man, was. It was a gray day, with only the three of us in the aviary, along with those big birds, very quiet and peaceful."

After Bldg 20 was built on the Hanover/ Page Mill Rd. site, and before the Addison garage was pronounced a California Historical Site, I wrote a short proposal to Dave, to combine some historic buildings. I proposed that HP move the first Addison garage, plus the second garage home of HP, behind the "Tinkerbell" Polly and Jake's Antique Store at El Camino and Page Mill Rd, plus the old Quonset Hut, WWII building at Page Mill and Birch, all over to the back lot of the Bldg 20 site.

My thought was that one of those buildings could serve as an archive and museum, for visitors to HP headquarters for decades to come. Packard called me over and told me that it was an interesting proposal, and that he would not oppose it if I wished to raise money to do it. But he said that he was totally uninterested in preserving all those old things.

I abandoned the effort, although I think I could have found enough money among some of Dave's contemporary middle managers, who had become fairly wealthy on HP stock options. I knew that some of them were more nostalgic about those buildings, since many of them had worked in them.

Sometime after the Monterey Bay Aquarium was finished, using funding from the Dave and Lucile Packard Foundation, I happened to be sitting across from Dave, at some sort of company management affair dinner. It was an informal event as most were. The aquarium project had been reported to have run $10 million over the original $35 million budget, and I couldn't resist tweaking Dave about it. He was always pretty hard on us, if our company projects couldn't stay within budget.

He smiled and actually looked a little embarrassed, if that was possible. He said, "Well, you know, John, we actually expected to run over, because we knew we were attempting things there that had never been done before." He mentioned the wave machine operation, the huge fiberglass mammal figures on the ceiling, and the serious technical considerations over those huge tanks and acrylic windows.

We all loved that man for his humanity, and much of it is preserved in that great aquarium institution, funded by Lucile and Dave, although almost none of the visitors ever knew him as a person. I have noticed as I walk through the aquarium, that his daughter, Julie, has done a superior job, enlisting hundreds of other contributors, in the years since, and carrying on that grand training site. Almost every day, it is filled with hundreds of kids and ordinary people, learning about our great oceans and the preservation of natural things. Dave had established an alternate home there in Monterey during those years of construction of the aquarium, and after it started in a hugely successful operation. It must have given him and Lucile great pleasure to see how ordinary people enjoyed that impressive facility of ocean science, and unique teaching resource.

Packard was known for only a few impetuous actions. On one occasion, when he was Chairman of the Board of Trustees of Stanford, he decided to take on two Stanford interns, one each summer. Both were "thought leaders," and editors of the Stanford Daily newspaper. He had them report to John Young, and in turn, to me in the marketing department. Their names were Kirk Hanson and Phil Taubman. They were bright and energetic young MBAs, and I set up some summer projects for them to evaluate a number of different processes in our marketing department. I also had one of them do a survey of work attitudes of my department in some detail. This was the first time I recall, that we used summer interns.

I found it interesting to follow the careers of those young men. Kirk Hanson came back to teach at the Stanford Business School after graduate work at Harvard Divinity, and for several decades taught business ethics. He recently moved to Santa Clara University, to run a new ethics department. He has considerable work going on now, what with the Enron scandal, and the serious condition of U.S. corporate governance. Phil Taubman went to Time Magazine, and became a senior editor, with a number of journalism awards to his credit. In a later interview, Hanson gave great credit to our summer employment job.

Another intern HP took on, after Packard returned from the Pentagon, was a young U.S. career service manager at a GS14 level, about mid-management in government ranking. Packard's plan was to have fledgling government managers spend 3-4 months at HP, learning the private sector methods and process measures, and bring them back to the Pentagon. I don't remember his name, from his project work at SPD, but I did remember his voice.

About a year later, I was on a business trip to Washington for other reasons, and on a spare afternoon, called Bill, an old USAF navigation school classmate of mine, who was assigned at the Pentagon. Bill was a Bird (full) Colonel, on the 5 th (USAF) floor. For reference, in my navigation cadet days in Texas, a Bird Colonel ran the entire base of 5000 men, but at the Pentagon, Bird Colonels were a dime a dozen. Bill was in a crowded office of about ten, 1-star Generals. If you were a 1-star, you got a desk and a filing cabinet AND table. Colonels didn't get the table. Anyway, as we were talking, I heard a familiar voice at their Xerox machine, and amazingly, it was the Packard intern I had met at HP. He just happened to come down the hall, because his own department's Xerox was broken down that day. Imagine that coincidence in a Pentagon with 25,000 employees!

Another occasion I am familiar with, was when Art Fong's wife, Mary, came down with a brain tumor, which required a serious operation. The operation was successful, but her rehab was long and frustrating. After she got back on her feet, it was either Dave or Bill who was talking to Art about Mary's recovery, and told Art to take Mary on a round-the-world trip, at company time and expense, to reward him for exceptional creativity. At one time, we, in Microwave Marketing had added up the estimated revenues of all the popular instrument projects that Art had managed. It came out to more than $200 million dollars. I think our calculation was made in 1980. This included the HP 8551A, 606A, 618A, 623A, 803A/417A, 614A and many others. An unusually-productive career.

In the late 1950's, Noel, the son of a Palo Alto minister, was the HP manufacturing manager. He was also the two-term mayor of Palo Alto, all at the same time. In his own way, he was a genius in being able to juggle these difficult jobs together. He would spend the mornings at HP, running the plant. He went to city hall for the afternoons. Evenings, he would return to the plant, reading memos, and typing small 3 x 5 "Portergrams" to everyone that needed jogging, using his two-finger typing method.

Noel Porter was a very popular figure on the production lines. Probably more than anyone else, he practiced what was to become "management by wandering around," later termed MBWA, in Business School case studies. The term was probably coined by John Doyle, the first Manufacturing Manager of the Microwave Division, and before it was recognized as a highly-useful management technique. Certainly Porter was popular with the assembly force, and all knew him personally.

My personal interactions with Porter were minimal. But in the 60's my family began an annual summer vacation ritual with a week at Meek's Bay Resort on the west shore of Lake Tahoe. It seems that the Porter family had owned a shore-side home up near Tahoe City for several generations, and opened the estate to the HP sailing club for a couple days of regatta, about that time in the summer. Although we weren't sailors, our family was invited up to enjoy the day on shore, with the generous and warm welcome of Noel and his wife.

My very first contact with Barney was described earlier in my HP job interview. Barney was an intellect in the genius range, with a purported IQ of 180. He was a classmate of Dave and Bill at Stanford, got his MS and PhD at Cal Tech and then went to work at the highest-prestige research lab of the world, Bell Telephone Labs (BTL) at Murray Hill, NJ. His work in WWII involved radar and other sophisticated system design, where his intellect made many technology contributions. Barney coined the word, "chirp radar," for its characteristics of a sweeping frequency, during the on pulse, which, in audio terms, would logically have sounded like a chirp.

Later, in 1959, when I used to make some sales calls at BTL with Bob MacVeety, our New Jersey Rep, I asked some senior engineers about their remembrances of Barney. It turns out that there were three certified geniuses at BTL at the same time, Claude Shannon of information theory fame, John Pierce, of communication satellite and traveling wave amplifier fame, and Barney. Apparently the three of those people were intellectually INSUFFERABLE. They were so bright and capable, and they cut an intellectual swath through that engineering community, that only a prestige lab like BTL could handle all three at once. I read about April 1, 2002, that John Pierce had just died at Stanford.

Barney was notorious for stress technical interviews with new lab candidates. I just got a small taste of that, before he turned me over to marketing. But it also carried over to his other activities too. He did not suffer fools lightly. In one conference room forum, one engineer's question from the floor, was answered with, "That was a stupid question! Next question." Needless to say even his own people were cautious around him.

Barney was a man with eclectic interests. His interests in the search for other intelligent life in the universe is well known. He was an early supporter for SETE, the impressive and sophisticated listening system, headquartered at the NASA research headquarters in Mountain View, CA, and with huge desert antenna farms in southern California. Barney had an interesting theory about other intelligent beings. He postulated that a planetary civilization might grow from an evolutionary process much like our own, leading to superior beings and equipment on some other planet.

He had actually worked out the probabilities of how many thousands of earth-like bodies, there might be in the cosmos, that were capable of supporting life. But he also felt that most such highly technical civilizations would die out within a thousand years or so. This led to the conclusion, that if there were some such intelligent civilizations, trying to communicate or transmit signals, if it took a million years to develop and die, that the probability that any two such would exist at just the same time they could transmit or receive, would be very low. Yet, the probability was not zero, and thus the Project SETE made some technology sense.

Barney also had a conservation side. I recall a monograph he wrote, about conservation of resources. He pointed out that of all the material goods we consume, we do an absolutely terrible job of recycling. He noted that atoms don't wear out, they just get misplaced. We start with a high grade ore in a mountain of iron ore, refine it, fabricate it, use it, and throw it into a dump ground where it is mixed up and lost to future generations.

I also recall an interesting observation he made, when laser technology was first invented. At the time, AT&T was postulating that they could build a 2-foot diameter pipe, which would stretch across the country, and be evacuated to a vacuum. By using large lenses periodically, they could re-collimate the laser light over the continental distance. Then, modulating with high speed digital data, they could replace their cross-country TH-microwave communications backbone, and their underground cable multiplex L-systems. Barney calculated that if you took laser light, and modulated it to only 1% bandwidth, you could modulate on one beam, all the conversations of the world. At that time, the world population was 4 billion people, but he then corrected himself to note that it was really 2 billion conversations, because half the world's people would be at each end.

In his later years, Barney helped found or served as technical advisor for a number of companies. One of these, was a company which grew and sold nematodes. He took great joy, in explaining that there were 500,000 species of nematodes in the world, and if you could find the right ones, and grew them, they would do wonderful things. His company, for example, found a certain strain, which ate corn-borers, the nasty little bug which could destroy a whole corn field by weakening the roots, after which the stalks fell down. His nematodes would multiply by eating the corn borer, and then when that food supply dried up, the nematodes also would die. A perfect silver-bullet pest-fighter, which was not toxic. He also noted that this was the only product he knew of, where the supplier furnished a microscope with each shipment, because the product was so tiny, you couldn't see it with the naked eye.

I happened to be in his group at the cafeteria lunch one day, with several of his top scientists from HP Labs. The sunspot cycle was just peaking, and one result was the disruption of the communications systems, due to the earth's ionospheric layer getting demolished by particles from the sun. One of the other serious effects, which almost no one knew about, was the vulnerability of the nation's electric power grid, to these same infusions of particles. The electric power grid of the U.S. is a delicately balanced and interconnected system, which allows power to flow from places of excess, like Oregon's Bonneville Dam, to California. It also supplies power in cases of emergency shutdown of major local generation facilities.

But the interconnection itself is also the key to making the system unstable. With high tension lines thousands of miles long, their characteristic of catching the effects of the sun's particles, makes the system unstable. As Barney and the others discussed the solution, which had already been the subject of many industry research projects, it was noted that with these power levels, one couldn't just "ground" things like in the lab, with a grounding strap. Barney suddenly proclaimed that some sort of rotating machine, which normally acted as a electric generator, could be modified to act as a floating ground, and the others agreed. I, of course,was way over my head, as usual in discussions with Barney.

Along in his career, Barney ran for the Palo Alto Unified School Board, and won a seat, and soon was Chairman. I don't recall if he was urged to get in some community service, perhaps by Mayor Noel Porter, or later when Packard had served his several terms as Chairman of the School Board.

Dealing with the public was probably not his finest hour, either. And Palo Alto, being a city with a major content of eggheads, college grads, included a high percentage of Stanford grads who didn't want to move away from the womb, etc (like me, I admit.). So he took some hard knocks in his early years on the board, but slowly the rough edges were rounded off, and he became a well-liked public servant.

Barney's technical expertise was well known to the high-tech community. When the Bay Area Rapid Transit (BART) system started construction in 1964, in one of their early rolling tests, one of the test trains approached the Fremont, end-of-the-line, station. Instead of slowing down, the train plowed into a pile of sand that some cautious engineer had insisted on providing instead of a hard bumper. Luckily the train was only traveling at about 25 mph, with no passengers.

One of our HP corporate managers, Jack Beckett, had been involved in industrial volunteering for some years, and at the time was Chairman of the Metropolitan Transit Commission for the Bay Area. Their responsibilities included oversight responsibility for BART, and such a serious operating computer failure was potentially catastrophic. It was crucial that the deficiency of the train control system be immediately investigated, so that the rollout of the system could proceed without concern about defective control.

The design for the BART was visionary, with the committee focusing on high tech cars and control technology. In retrospect, it was probably not a good decision, and the committee would have done well to visit Europe where they had for decades built and operated rugged and reliable cars and control systems that were designed for fail-safe performance. Westinghouse was the main contractor chosen for their futuristic control proposal. But there were to be revealed a number of black-holes in their design.

Beckett immediately got his Board to appoint a technical study commission, chaired by Barney. What they found was troubling. The objective of the original proposal was to have a system of trains running at up to 90 mph with a 3-5 minute headway (4.5-7.5 miles) between them---without human operators. Geez, there is a design just begging for fatalities. The train control consisted of a radio link between the speeding train and an endless antenna running alongside the tracks. The braking system of every train was controlled by an automated built-in stopping profile determined by the wayside electronic signaling system based on the distance ahead of another train. This "local" train control was augmented by the central computer system (big-daddy) in Oakland.

Dave Cochran later filled me in on some of the project details. On the day of the "crash," the car detected its approach to Fremont station, and sent its signal to the speed control system in the train to call for the beginning of brake action. However the 27 mph crystal had shorted and the speed control system went to a free running oscillator that happened to call for 70 mph. The system had not been designed "fail-safe," i.e. to stop if the correct speed could not be attained. The on-board human operator operated the emergency brake, but the few-second hesitation was enough for the train to over-run the station.

The upshot of that revelation resulted in a scathing letter that Barney wrote to the CEO of Westinghouse. In essence, Barney accused the company of dereliction of engineering responsibility and suggested that they must have assigned their poorest engineers to the tasks. Redesign took place immediately. I believe that was the year that Barney had been elected to the presidency of the IEEE, the international society of professional engineers. So his words had extra impact on Westinghouse.

Another system design flaw was discovered in a "phantom" train problem. It seems that Westinghouse did not use the decades-old design practice of train detection, as practiced in Europe. Instead because of the continuous welded rail to eliminate the clickity-clack, they had to design a monitor which measures the electrical impedance between the two rails by the steel wheels of the car touching both rails. The problem is that Westinghouse didn't count on the nasty environment of the rails, oil, dirt, corrosion and water that meant that the impedance changes weren't sensed correctly.

The urgency of a fix was paramount, since the system was close to coming on line. The upshot to the Oliver study was to quickly design an alternate system to ensure continuous detection. In the interim, human operators at each station would provide input (they would call the up-line station and tell them to release the train) so that the main system operating displays were assured. For a time, a given train could not get a command to leave a given station if an operator at an advanced station had not given proof that the previous train had left a future station.

Out of the Oliver commission came a "Logic Back-up Train Detection System" based on the fact that trains cannot appear or disappear from the track. A simple wayside logic system with each block (minimum detectable length) contains the presence of a train once detected. It cannot be dropped until detection is registered in the successive block. The wayside system daisy chains this all together. If movement of the train is not detected in the next block, the stopping profile remains behind in the original block.

This concept was designed by Len Cutler and Dave Cochran solicited by Barney for his commission, a patent was received for the idea with BART granted a royalty free license.

The final upshot of the Oliver Commission was that BART service came up on time, ran for some years with the duplicate control systems and human operators giving individual approval for a train to leave particular stations based on a prior train being seen leaving a station further along, making the tracks clear. During that period, major redesign took place in the entire system control computers, sensors, with the "Logic Back-up System" integrated in a fail safe manner into the central computers. Now, 30 years later, the BART operation has been remarkably free of dangerous crashes and failures, never has one train hit another.

When Barney's R&D lab was located in Bldg 1U, newly-hired lab engineers would often find some unexpected results on their oscilloscope displays when probing their circuit waveforms. It was sort of a ritual of passage, because their senior engineer associates would usually keep quiet about the effect.

If all the conditions were right, what the engineers would see was that their expected waveforms would be OK, but every so often the circuit would go wild with large repetitive pulses ruining what they thought was their prize stable circuit. It wouldn't happen regularly, and the period of occurrence was about every 9 seconds. But a circuit that runs wild is not an acceptable one, and the phenomenon would sometimes drive the poor engineer crazy trying to figure what was going wrong. About that time, the seniors would charitably explain what was happening.

The south-looking glass windows of Bldg 1 faced almost directly south to Mount Umunhum, 25 miles away. A very long-range USAF sea-search radar was located on the top of the mountain, and its antenna rotation period was just 9 seconds. When the location of probing wires and the circuit was just right, the high power radar pulses could be acquired by the loops of wires, and presented on the scope display. Even though the frequency of the microwave signal was well above the video scope display, the radar signal was strong enough to overload the front end, high sensitivity amplifier and would self-detect to provide a video-like pulse.

It had another effect as well. When Barney had come back from Bell Labs to HP, he brought with him a profound affinity for high quality audio. In those years, HP used a plant-wide paging system, with speakers in all buildings. Although it was good quality audio, it was not up to the standards of Barney's quality ear. So he undertook to re-design the power amplifiers with exceedingly low distortion and hum and all those bad audio signal things.

The paging telephone operators were located in their switchboard room at the inner corner of Bldg 1 and 3. They, too, were exposed to the Mount Umunhum radar illumination signals, and you guessed it. Sometime after the new audio amplifiers were installed, again when all the conditions were right, one of the operators voice cables served as an antenna, and fed the repetitive pulses into the audio amplifier. In this case, when the system was keyed, a loud buuuurrrrrpppp sound occurred. Each time that operator keyed for a page, it burped.

Barney called out a couple of his engineer crew with audio credentials to look for the problem, because it sounded like an uncommon defect in audio amplifiers, called motorboating. Could Barney's magnificent amplifier be a victim of that serious defect? You can also imagine that looking for this intermittent effect was pretty discouraging for a time, but they soon figured it out. And with a few simple input circuit modifications, any voice cable position was soon insensitive to the effect.

Ralph Lee treated the spending of HP's money like his very own. A manufacturing manager in the mid-1960's, he was known for his frugal control of budgets, yet creative manufacturing skills. Later, as he became Group Manager and Executive VP, he became better known as the office partition fighter. As HP's divisions moved to outlying cities, the traditional HP "bull-pen" style of large, open bays of desks and engineer benches would give way to wall partitions, as the local management moved to be more like other companies. More than once, on a Ralph Lee visit, he would call in the local facilities people, and order them to begin dismantling the offending partitions and private offices on the spot. Word got around.

Yet, Ralph's parsimony was itself balanced off on occasion. At a Monterey Management Conference I attended, Ralph used part of his manufacturing overview to present a slide showing that inventory control of hand tools was failing. He put up a slide, which showed that HP had purchased about twice as many sets of hand tools, as we had hired new technical people, and that it amounted to maybe $60,000 per year.

Bill Hewlett was sitting in the front row, and suddenly stopped the presentation with the question, "Hold it right there, Ralph. What's your point?" Ralph then pointed out that it looked as if many of the newly-hired engineers were stocking up their home workbench.

Bill's reply was certain to be remembered by all managers present. "Look," he said, "our R&D strategy is to hire mostly young engineers, right out of college. For many of them, this is their first big-time job. We look for those types of young people who are busy with other technical hobbies, beyond work, like ham radio, fixing their cars, audio and sound system aficionados. We'd like them to learn which end of a soldering iron to pick up. If that means that we have to buy two sets of tools for every new hire, that's the right thing to do. And they should have access to reasonable parts from the lab stock too."

Another common-sense rule, which made our HP engineers feel like they were appreciated.

Part of the reason for HP's specific attention to microwave research was undoubtedly the fact that Bill Hewlett had recruited several engineers from WWII research facilities on the East Coast. Bruce Wholey, who later advanced to Microwave Division Manager in 1962, came from Fred Terman's Radio Research Lab (countermeasures), at Harvard University. R&D engineer Art Fong came from the MIT Radiation Lab (radar research). And there were a number of others with experience in microwave instrumentation.

Bruce was a roughhewn-appearing and gruff-sounding Canadian-born man. He would answer the phone with a gruff, "Halllowww." He sounded like you were the last person he wanted to hear from. But he was really a pussycat, and quite a warm manager. His main failing, if you were to ask most of his engineers, was that he would come over to their lab benches to chat, and then smoke almost continuously. Worse, he would drop the expended cigarettes on the tile floor underfoot, and stamp them out with his shoe, so the engineer's area would smell for the rest of the day.

When HP first bought Sanborn Corporation, it seemed like a pure cash-flow machine. Although its main business was medical electrocardiographs, the product line also included multi-channel pen recorders, which were in great demand during the aerospace race in the Cold War. Those multi-channel recorders were used for the large test systems for printing out mechanical vibration performance on things like airframes. The line was being sold by the Independent Reps that HP was already using. In many cases, the same Reps already handled both Sanborn and HP, so the fit was automatic.

But, I have always felt that Bill Hewlett was out looking for medical instrumentation for HP, since his father was a doctor. In a real sense, measurement technology, applied to medical science, was exciting and productive, and offered contributions to the human endeavor. I think Bill saw that as a place where our technology-driven company could make some real humanitarian contributions.

The medical electrocardiograph business was like the razor-razorblade business. Sanborn's product was top-of-the-line, because their design used a recording paper called Perma-paper. It was a paper sandwich with a black background, covered by a clean white wax coat. The black only showed through, when a heated stylus, on the end of the recording pen moved across the surface and melted the wax, revealing a stark black line on white. In doctor's offices, any sort of liquid ink process, that caused splattered dots and blotches, was not acceptable. The Sanborn paper was exceedingly clean, so the record could be stapled into the patient's medical file folder.

Sanborn's problem was that their business model looked at the 60,000 U.S. primary care doctors as a cash-flow machine. They more or less gave away the cardiograph machine, in order to sell the high-profit paper. But the crucial fact, that somehow the HP acquisition managers failed to grasp, was that the 17-year patent for that special paper was about to expire. When that happened, shortly after HP became the new owner, the sub-contract paper manufacturer, Nashua Paper Products, started selling the paper directly to the doctors at a big discount. And a huge amount of revenue disappeared.

HP kept corporate management hands off for a year or two, but then Packard called on Bruce to move out to manage the recovery. Part of that recovery strategy was to inject more of HP's high-tech computer and system skills, and to begin to de-emphasize the individual doctor customer. This led to HP's move into intensive care system monitors. By exploiting HP's sensor technology and new computer system capabilities, the large systems found a much better fit to the HP field sales organizations. They just weren't equipped to answer phone calls from doctor's offices, on a weekend, to deliver a few dollars worth of Perma-paper. Furthermore, some revolutionary medical instrumentation breakthroughs resulted for HP as well, by emphasizing the large sophisticated intensive care monitoring.

Lyle passed away on Easter Sunday, 1988. Although retired from HP since the mid 1970's, many of the people from the old Microwave Division remember him well, as well as his true impact on HP. In his early career, Lyle worked on instrumentation for the oil well industry in the Bakersfield, CA area. He later worked on the MA-l fire control radar, at Hughes Aircraft Company, when owner Howard Hughes was still out in public.

Lyle told of nights, when they were on the Hughes Company flight line, after midnight, readying a fighter for a test mission to the California desert gunnery ranges the next day. The Hughes airstrip is still in Los Angeles, just about 3 miles north of LAX, and with a runway running parallel to LAX. Some nights, as they worked, a well-maintained DC-3, with a large bay window on one side, would land, and taxi over to the project workers. Pilot Howard Hughes, in old sun-tan pants would get out, roll up his sleeves and work along with the engineers.

Lyle gained most of his HP fame during the introduction of the HP 8551A Microwave Spectrum Analyzer, in 1964. This was a brand new product sector for HP, with the main competitor being Polarad Corporation (not the film-maker, Polaroid) of Long Island, NY. Their business was about $5 million, out of a total market of about $8 million. They sold their instruments for about $5,000 while Panoramic, Inc., also of Long Island, came in about $7,000. Little foreign competition existed.

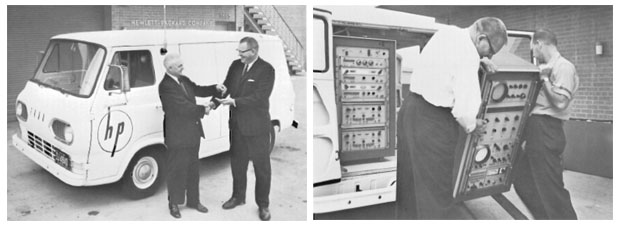

Lyle was working as Microwave Application Engineer at the time, and correctly predicted that the HP field engineers would not be able to come up to speed quickly, on applications and measurement techniques for this brand new technology. He proposed for HP to buy him a Ford Econoline van, equip it to mount the HP 8551A in a rack at the rear doors, for easy access or removal, add an Onan AC power generator, and to take the show on the road. While not intuitive at the beginning, it was an enormous success.

|

| (Left) Earl Lipscomb, Manager of the Southwest Sales Region, presents Lyle Jevons with keys to the Ford Econoline van. (Right) Lyle and John Smylie of Dallas show how spectrum analyzer demonstrator rack can be moved into a customer's plant. From Measure Magazine December 1964. Courtesy of the Hewlett Packard Company |

Lyle spent probably 6 months on the road, slowly moving across the country, working with customers, always in the company of the local FE, and thereby teaching each one those new applications at the same time he was selling to the customers. We began to see orders arriving from customers, often tracking Lyle's travels, as did the applications stories from the FEs.

A typical application was in the Antelope Valley, about 50 miles north of Los Angeles, the home of Edwards AFB. Accompanied by an Air Force Colonel, who was the frequency-control officer at Edwards, they parked the van alongside a phone booth at a desert intersection of Route 15 and 66, north of the base. The USAF problem was that there were three long-range surveillance radars, NASA, USAF, and FAA, all operating in S-band frequencies, on three separate mountain peaks, whose signals were interfering with each other.

It was the Colonel's job to straighten things out. The new HP analyzer, with its exceptionally-broad, 2,000 MHz sweep width, could see all three radar signals at once. The 60 dB dynamic range revealed the signal spectrum modulation "skirts," which were overlapping each other. The Colonel got on the phone booth phone (before the days of cellular), calling each radar technician in sequence, and unsorted them quickly. Lyle reported that, as he drove away that day, the Colonel offered him $100,000, if he could have kept that demo analyzer.

Several other field demos come to mind. As Lyle travelled across the US, he would call in to report on new applications, which led us to compile these into a follow-up application note AN 63A. The definitive product launch application note was the blockbuster AN-63, an all-time "best seller."

For Lyle's visit to the FAA, Federal Aviation Administration at their huge complex in Oklahoma City, Lyle reported that for scheduling reasons, they didn't have time to wheel out the demo rack from the back of the van, to push it down for a long aisle, into the building for a demo next to some radar equipment evaluation. So they gave him permission to actually drive the van itself for about 200 feet into the building. Could you do that today? Not likely.

Another new application for the 8551 that Lyle conceived during a weekend layover, when his curiosity about his van ignition system emissions led him to make some measurements. Lyle was a Ham Radio operator, so he fashioned a simply dipole antenna and began to trace out the noise sources inside the engine compartment, and thereby leakage into the passenger compartment.

This led to a formal demonstration at the Ford Motor company in Detroit, when his tour brought him to that industrial complex. The 8551 Analyzer turned out to be ideal for such RFI evaluations on automobiles because of its very wide frequency coverage as well as it's excellent sensitivity to broadband noise.

We sold many units for this application, described in AN-63A, into the RFI market where HP had zero penetration before, even though we didn't measure absolute levels of RFI signals per accepted test specs. Our unit found where the problems were, and specialized RFI receivers could measure per spec.

Lyle's applications trip was a long one, and not as glamorous as one might think. Lyle would get to feeling sorry for himself. Although he technically reported to me, as Marketing Manager, maybe once a month Division Manager John Young, would come over to my desk in the morning, with the exclamation, "Goddamn, Jevons, he called me at home last night at 2:00 am to resign. I had to spend an hour talking him out of it."

John also agreed to an unusual process for Lyle's expense accounts. Lyle HATED bureaucracy, so John arranged for his own secretary to actually fill out Lyle's expense reports once a month. Lyle would mail in all his expense receipts, and tell her how much money he withdrew from a particular sales office petty cash, and tell her how much cash he had on hand at the beginning and end of the period. She managed to compute his line item expenses and John signed them. Can you imagine any other HP employee being allowed to do that? I don't think so.

The next year, Lyle shipped the entire van to Europe. He used the same technique of customer visits with the FEs. Lyle enjoyed himself in Europe, but at some border crossing, one afternoon, the customs people were giving him a hard time. Then they noticed several 3/8-inch puncture holes on the sides of the van. When Lyle was asked about them, he simply smiled and said, "Indians." That made things more friendly, and he passed easily.

Lyle was a man of varied interests, one of which was that he was a confirmed theatre organ buff. He was personal friends with Howard Vollum, president and founder of Tektronix, with many contacts in an organization of theatre organ aficionados. He told of the last days of life for the massive Wurlitzer organ, at the Fox Theatre in San Francisco, before they tore down the old place. Thousands of theatre organ fans showed up for concerts that ran from midnight to dawn. Lyle was part of the behind-the-scenes crew which worked the fan room, where they had to keep wet towels on the drive motors for the air blowers, which heated up so much from hours of playing.

Lyle built his own aerobatic airplane, and flew it. He was a ham radio operator who worked on amateur radio high-tech experiments like moon-bounce tests.

He retired from HP to his own small fly-in ranch, just outside the boundaries of the U.S. Army's Fort Huachuca, near Tombstone, AZ. The base was a major testing area for military communications and battlefield signal environment simulations. We kept in touch. One day, Lyle called me, "John, what do you know about VAST?" I said, "It's a $4 billion dollar program for the Navy, for automatic testing of avionics on U.S. Navy aircraft carriers. Each unit has 16 racks-full of equipment, running with a Varian computer, and costs about $500,000. Why do you ask?"

"I've got one."

"Wait a minute, Lyle, you didn't hear me. These things cost 1/ 2 million, etc, etc."

"I've got one."

And indeed he did. It turned out that in his work with friends on the MARS Ham Radio Club, at the base, the club got first refusal on any electronic equipment that was scrapped. So when this huge testing system was scrapped, the MARS Club brought it to Lyle's fly-in hanger, just off the base, to salvage it for the gold in the printed circuit boards and relays. The club used proceeds to help fund their operations. Lyle was asking me to see if I could find operating manuals for several pieces of HP gear that were part of the system.

In his retirement, Lyle signed on as flight engineer with a crew of retired airline captains, who were flying a 707 freight charter, to and from Australia. The mission was to fly back a load of 20 tons of mutton. The 707 was of British service, configured with Decca (UK) avionics, and some electrical controls that Lyle wasn't all that comfortable with. The flight out was uneventful, LAX to Hawaii to Guam to Adalaide to Alice Springs. The mutton was not frozen, with the idea of a short return flight. On the leg back to Guam, one jet engine bearing began to overheat. They shut it down, but did not declare an emergency, or report it to the ground, fearing any delay would cause obvious spoilage with the load. So they took off with four engines, and immediately shut down one. On to Hawaii, same technique.

On the Hawaii-to-LAX, other things went wrong. The shut-down engine used no fuel, while the others used too much. But there weren't any on-board instructions on how to transfer fuel between tanks. In the process of trying to find the right switch combinations, an electrical fire developed in the control panels. This burned out their long-range radio. So Lyle got the fire out, used short-range radio to relay messages to LAX, via other in-bound flights, and finally landed with the mutton in LAX. Typical Jevons, overcoming adversity unabashed.

Carl Mahurin was the Dean of the HP Service Department, and was probably the single most significant factor in establishing the culture of the way HP dealt with service customers. Carl was a graduate agronomist from Stanford. When WWII came, he looked for a job with industry and came with HP. Through his early assignments, he came to run the service department in the basement of Bldg 8, at the corner of Page Mill Rd. and Park Blvd in Palo Alto. Finding a photo of Carl was not a trivial task, because in spite of his many decades of HP service, he actively avoided getting his picture taken in later years. This one came from a 1950s-era company basketball team shot. The incongruity to those who knew Carl in the 1970s was to be told that in his college days at Stanford he was a highly-accomplished athlete.

Carl was the consummate politician. But he knew innately the way to get what he needed. A typical example was his training department's move into new quarters in Bldg 11, at Page Mill and El Camino, in the early 1970's. By that time, I had transferred, to run a small department designing and producing light emitting diode (LED) products. My LED production operations were in the back of Bldg 11.

Since Carl's training group welcomed hundreds of customers to HP's world-famous training courses, Carl wanted a warm and friendly facility, with carpeted floors, drapes, reception areas with comfortable sofas, etc. He assumed that such plush surroundings would fail the budget test with his boss, Noel Eldred, and the long-held HP culture of tile floors, no carpets, and spare accommodations. What to do?

Carl enlisted Jane Neely, wife of Norm Neely, our California representative, and senior spokesman for sales techniques. Jane had done the interior decorating for perhaps a half-dozen of Norm's far-flung sales offices. They were well-known for warm hospitality, and a Spanish architecture, each with their "Cahuenga Room" bar for after hours informalities.

Jane designed for Carl a perfect combination of orange carpets, beige sofas, patterned drapes, classy coffee tables, etc, for a mere $50,000 budget. Which boss Noel Eldred promptly vetoed. But Carl was ready for that. He called Jane to tell her the bad news. Who promptly called Norm, who called Packard. Who called Eldred, and got the decision reversed. So Carl got his elegant facility for customers, and it was a grand spot. No bar in the factory, however.