My Life at Hewlett-Packard, by Carl Cottrell

ForewordIf you hired on at Hewlett-Packard in the early 1950s, like Carl, you joined a very small company, less than $10 million revenues, less than 500 employees. Carl's badge number was 617. This simply meant that even though Dave Packard had grown the company from zero during the WWII years, with Bill in the Army, everyone was still learning how to deal with serious growth. The small partnership had gone through a 1/3rd downturn right after 1945, as the military business of WWII went away. But by the 1950's, business was back on a growth curve, and it became a matter of hiring enough skilled people and engineers, working to improve the manufacturing processes, and learning how to manage all these affairs with new skills and judgment. Not surprisingly, with Bill and Dave both now in charge, the workplace was beginning to show signs of the personal concerns that HP management had for their people. Those principles had already taken root, and that company culture later became titled as The HP Way. When I hired in, in early 1958, the engineering management had already settled on a standardized practice for all new engineers. They got a 6-month "orientation," out on the production line, with some of that time spent in the Carl Mahurin "Charm School," which was the Service and Training Department. Carl Cottrell was my first boss. When I reported to Carl, he sent me to 2 weeks on an assembly line putting together the basic chassis of an RF signal generator. Then I was ready to join the Service Dept, to learn to diagnose and repair customer instruments, and to write letters of reply to customer inquiries. Most newly-graduated BSEE's didn't think too much of that practice, although years later they admitted its value. But in my case, literally on my first day in Service, Carl Cottrell showed up and convinced Carl Mahurin that I was desperately needed upstairs in the Applications group, and thus caused me to miss that legendary Mahurin "learning" experience. I still thank him for that. Carl's own experience, as he entered HP was typical. He came with military experience, then a technical education from DeVry in Chicago, and began in the test department. There is no better place to learn instrumentation and measurements than handling actual products, testing for performance, with a rackful of other instruments. You learn the critical importance of accuracy, specifications, reliability of components and in those days, vacuum tubes. You know of disappointment that customers might face if a product won't turn on or show bad performance. And yet you face the pressure of getting shipments out, to meet the financial goals too. All of this gets balanced by honest management, so you learn those principles too, from your managers. Soon Carl was moving to the Service Dept., which at that time also took responsibility for technical training. This settled his mind that he would set his career to be marketing and big time management, not production. The training responsibility began to involve more than just newly hired engineers, because all of the dozens of new field sales engineers, who were being hired, needed a school of instrumentation and measurements. They got to sit on a repair bench, under the supervision of some hardened electronic tech, who had forgotten more than they ever learned in engineering school, about circuits and diagnostics. The techs used to joke that many of these new guys, who weren't ham radio or audiophiles, didn't know which end of a soldering iron to pick up. Such ad hoc training gave way in later years to a formal 6-week instrument and measurement seminars. Carl moved quickly through many marketing functions, applications, quotations, trade show planning, and then sales force region management. The title "manager" in that case didn't mean much, because those old sales companies were run by owners who were personal friends of Packard, so while we used to write our title, "region manager," we knew we were more like Region Sales Clerks. Those owners negotiated annual quotas and financial affairs directly with VP Eldred and Packard, who were personal friends of those reps. Carl was soon on his way upward in management. He accepted the General Management of HP Europe, just as it was hitting a huge growth curve. I remember that the whole continent revenues were about $5 million in the 1958 period. By the time he left, just a few years later, they exceeded $30 million, a remarkable feat, because Carl had to dismiss the old Sales Companies and set up entirely new HP-only country sales offices with all new people. This HP Memoir was partially based on an oral history of May 16, 1995, with Al Bagley, who in retirement, accomplished many such interviews. Carl then added on his more recent memories of work in Field Sales Regions and especially the development of HP's strong presence in Europe. Without doubt, Carl's memories cover a long and successful career with many achievements. He shows the unique intersection of superior products, customers of many nations, enlightened management, technology breakthroughs, personal friendships, and a great deal of fun in those years of high technology. Read on to discover it all. Carl decided that we should go ahead and publish this first installment on his life and times at HP. As he writes additional retrospectives on his other corporate assignments, we will add to this memoir. John Minck |

My Life at Hewlett-Packard, by Carl Cottrell

My Life at Hewlett-Packard,

by Carl Cottrell

Born into the Great Depression

I was born February 2, 1928 - I'm a groundhog-in Ocala, Florida, which is about in the center of the state, a bit south of Orlando. My father and mother were from Tennessee and North Carolina respectively. They lived where the two states come together, up in the northwestern corner of North Carolina and the eastern corner of Tennessee. They were married in 1925.

My mother had been a secretary for a lumber company and some other people when she met my dad, who was a mechanic. He was an expert, first on Model T's, and then later, on Chevrolets. In '28, times were pretty tough in North Carolina and Tennessee and the Florida land boom was going on, so my father and mother went down to Florida to try and make a living. That's how I happened to be born in Ocala. My dad was working for a warehouse down there at that time.

But the whole economy went belly up two or three years later-leading to the Great Depression. So when I was about three, they went back up to North Carolina. By now the depression was well under way and times were really tough. I didn't appreciate that, but I guess we were dirt poor. My dad had job after job. He would work anywhere at anything, whether as a mechanic or running a road grader. He was doing all kinds of things.

A daughter-my sister-was born, but died when she was three, and I was six. She died of pneumonia. Then my brother came along in '36. My mother had a brother who was living out in Santa Cruz, California, and was working for the Santa Cruz Lumber Company. He was secretary of the company and had a steady job for a long time. In 1938, he learned how tough things were for my family-by that time we were living with my grandparents in Tennessee-so he sent my folks a hundred dollars, which was a small fortune.

My dad had a '32 Buick. We loaded everything we could into that Buick, including us two kids, and came across the country to California in 1938, when I was 10. I kept a diary and it took us ten days. It was an interesting trip. I talked about seeing all the poor people along the way (like we weren't!). I still have that diary and I look at it every once in a while to remind myself of how desperate things were.

We arrived in Santa Cruz in February of '38 and I've been a Californian ever since. My father got a steady job with Santa Cruz Lumber Company. I went to elementary school and part of high school in Santa Cruz, then we moved. The Santa Cruz Lumber Company had a saw mill up above Boulder Creek about ten miles north, and we moved up there when I was a teenager. I finished high school in Boulder Creek in June of '45, just as World War II ended. There were two boys in our class of thirteen in that school.

In World War II, there was a shortage of male help in most places, and the saw mill town where we lived was no exception. By the time I was sixteen, when I could legally be employed, I worked in that mill. I had all kinds of jobs in the saw mill itself, out in the woods, working with both logs and the finished lumber. I filled in about every kind of job you can name because I was a pretty health kid and I was pretty strong. That occupied a great deal of my time.

I don't recall that I had any particular hobbies or interests then-except cars. I'd been fiddling around with cars for quite a while, and like a lot of kids, I fixed cars and we learned how to run Ford Model A's on kerosene and anything else that they would burn, and, of course, we learned how to siphon gas -- which could get me a jail term in these days. The first car I owned was a '33 Chevy sedan. It was shiny black with white side walls and I thought that was the most marvelous thing. It was a great car.

U.S. Army

When I graduated from high school, as was not uncommon in those days, I turned eighteen in February and I got married. My first wife was a local girl and member of that high school class. We'd been going together since we were sixteen, and, like I say, it was not uncommon for people to want to leave home and get on their own. So I got married at eighteen and within a month, had my draft notice. I went off to the U.S. Army in '46. At that time, we were still in a state of war. The war had not yet officially been declared over. In fact it wasn't until two or three years later that the thing was over from a conscription point of view.

The reason they wanted to keep the draft going was because they needed replacement troops, and they needed people to come into the service and replace the masses of military who were being mustered out after years of service and deployment. The nation still showed a fairly high level of troop support for quite a while. So even though I wasn't in the fighting of World War II, I'm legally considered a World War II veteran. So I got all of those rights, privileges, and benefits.

I didn't wait to be drafted, but I did enlist in the regular army because if I got drafted, it was for an indefinite period. By enlisting, I could join the regular army for a specified eighteen months. So I said, "I'll take the eighteen months." I never did figure out if that was a good decision. The next thing I know, I'm leaving my bride and I went off to Camp Polk, Louisiana for basic training. Millions have gone through it, but military basic training is one of the great negative experiences of this country. After a couple of months of basic training, they put us on a troop train and sent us up to Camp Stoneman, here at Pittsburg, California, where they were going to ship us off to Korea. That's where my lucky charm stepped in, and where I had a fortunate experience.

The Military commanders had kept the draft going because Korea was already heating up politically. Our entire company was headed to Korea, but about the second day at Stoneman, one of our Sergeants asked if anybody knew how to type. I did know, and I raised my hand, in spite of advice we recruits always got, which was to never volunteer for anything. But I did volunteer, got pulled out of the ranks and made into a company clerk. That caused me to stay in Pittsburg for the remainder of my tour, typing and doing other things that company clerks do. The best part was that I was able to stay in Northern California.

DeVry Institute and Chicago

I left the military in 1948 and was only twenty-one years old. I didn't know what I wanted to do, although I had two years of GI bill racked up by then, and I wanted to use that. So, temporarily I went back to the Santa Cruz Lumber Company. I drove a lumber truck and trailer-one of those eighteen wheelers-for the next couple of years. We had a son. But when he was two, I was getting kind of tired of doing what I was doing, so I had a long conversation with my mother about all that. She suggested, "Why don't you try electronics?" It was a new buzz word and I'd never thought much about it. But I wrote to an outfit - a correspondence school called DeForest Training - and they sent me a complete information kit, books and instructional things. Pretty soon I was building a radio and I had wires strung through the trees for an antenna and I really enjoyed that.

The school later became known as DeVry. The DeVry Company had become successful making movie projectors. That was their claim to fame. They made most of the projectors that were used in national theaters. Mr. DeVry, who started the company, was a great admirer of Mr. Lee de Forest, an early electronic inventor. He started his school, because he had a great interest in training people, he named it De Forest Training.

They had a resident school at that time. I got so interested in this school, and I recognized that here I was married, had a son to support, but had two year's worth of GI bill subsidy coming. So where could I go to get the most out of all this, in a relatively short time period? I decided to go to Chicago to their resident school. So, the family, wife and child moved back there. We had a pretty rough go for a while because the GI bill funding took a while to kick in. We didn't have much money. I worked after school in a factory that made metal parts for furniture, couch frames, chair frames. I ran a punch press - all that kind of thing. My wife got a job and worked, and we lived in a little one-room studio on the near north side. That went on quite a while until I got far enough along in school, probably 9 months, that I learned how to fix TV sets.

I also had about a prior year of correspondence school time. So I was pretty familiar with TV circuitry and that kind of thing. They moved you along pretty fast in this school because they concentrated only on electronics and math and technical subjects. It was a six hour day plus lab work and homework, so it was fairly intensive. We moved right along, and by the time we had been there nine months, we'd already built a TV set from the ground up, designing and winding all the coils and such. We did everything but the tuner and the picture tube.

Then I got a job fixing TV sets, and that was quite an experience. I would go to school all day and then I'd get my car and go make my repair calls and drive all over Chicago. I went to every part of Chicago, through these ethnic districts, to fix people's TV sets. What an experience for a young man, with little knowledge of the world. I still remember a lot of that to this day, through the summer and the winter. There were lots and lots of poor people, who just had nothing but a TV set, you know. My service call was three dollars, plus whatever materials I used, and lot of people couldn't even come up with the three dollars after I fixed their TV set.

|

"Mad-Man Muntz" was an early marketing genius for the lowest price television sets. |

You always tried to fix the TV sets on site, because it was hard to get people to part with their sets. Generally you could fix them on the site; but maybe one out of every fifteen sets had a really serious problem that you couldn't attack in the home. Then you'd have to tell these people you'd have to take the set in and, boy, that was like pulling hen's teeth.

I worked on many brands of TVs. One of the popular ones and one of the cheapest ones was Muntz. A guy named Earle Muntz (Recall the TV ads, "Mad-Man Muntz") made a fortune on these cheapo TV sets. One of the most complicated ones was DuMont, who built great big Cadillac-type sets that didn't work any better than Muntz, but they had a lot of bells and whistles. Then there were all those brands in between. There was Zenith and there was Philco, a big name. But once you got inside, the basic TV was pretty much the same. Those were in the days of vacuum tubes, of course, so often the fix was a burned out vacuum tube, with a simple tube diagnostic and replacement.

|

Muntz had a penchant for personal appearance TV ads, and even billboard media. |

I put in long days. I'd go to school all day, then I'd work six hours fixing TV sets, typically from, say, 4 pm until ten at night, then I'd come home and do my homework. It was a grind. The coursework was designed to be covered by the GI bill, as many schools and universities were operating in that postwar period.

In 1952 I graduated - at the top of my class. Most of my classmates were like me, ex-GIs, about 35 in my class. There were no women instructors or students. It was an all-male school at that time. But we had some great experiences there. I thought it a pretty fair education in terms of what we were trying to accomplish.

Our curriculum was heavy on science, we had algebra, trig and calculus. We didn't get as far in calculus as I would have liked. Some physics, but not a college level. Of course there were no humanities, since the objective was to impart the most critical elements to land a technical job. In later years they added a little bit of history, English and such, but mainly we had math and electronics.

One of the goals of the school was to get your first class FCC license as you graduated. We all prepared for that because in those days you couldn't do any mechanical work in a broadcast studio without a first class FCC ticket. Following WWII, the nation was catching up on broadcast equipment technology, and the popular new television personalities made it a booming field.

A lot of us thought we wanted to work in the broadcast business as station engineers-broadcast engineers, TV engineers and all that kind of thing. I don't know what the rules are today, but in those days if you were anything but a front-of-the-camera performer, you had to have a first class ticket. There was a rather tough written exam for that, somewhat comparable to the California Professional Engineer qualifications. It had lots of theoretical questions, circuit-design questions and all that sort of thing. Surprisingly, most of it had nothing to do with a transmitter.

The coursework I took did not qualify for any degree. Later on they added an English course and qualified it for an Associate of Art degree. I was ahead of that time. Dick Alberding followed me by some five years and went through that curriculum and got an Associate's degree. I think they then renamed the school DeVry when they added humanities. This was happening as the GI bill was winding down and they had to attract new non-GI students.

I graduated in '52. We still had the one child, who was just 3. So we headed back home to California and decided I would apply around the bay area for work, The first thing I discovered was that there weren't too many places to get a job. And I also discovered there weren't very many jobs at those places. I interviewed at Varian, Hewlett-Packard, Sierra Microwave, which made microwave components, and perhaps an instrument or two. Dalmo Victor was big in power tubes-transmitter tubes, radar tubes, that kind of thing. Ampex was a big name, making audio tape recorders. I didn't bother with Eimac and Lytton because I didn't really understand their products.

I was really interested in Hewlett- Packard, because when we'd been going to school they would talk about measurement instrumentation, and we used an HP oscillator. There was quite a bit of discussion in the classroom about Fred Terman's engineering books, and some of its circuitry. So the name HP would come up, and I knew more about them by this means than any other company out here. I went around and made all these applications in June and July when I got out of school but didn't get any offers. When I got to HP, I was interviewed by Anne Laudel, the combination receptionist and informal head of personnel.

She screened me and decided I ought to have George Blanchard's test. George Blanchard had a written test that he gave all the applicants in those days. I suspect it wouldn't be legal now. Well, I took his test and I knocked it dead. I can still remember the test, it was nothing compared to the FCC test I'd just completed. George was really impressed with that, but he said, "I don't have any jobs to offer you right now."

Finally a real electronics job at HP

By this time we were out of money. We were living with my in-laws in Boulder Creek and there was a little radio repair shop in town, so I luckily got a job there. I fixed radios until along about September, when I got a call from George Blanchard to come to work. I started my HP career September 15, 1952.

My first job was in the test department. I checked in on the morning of September 15, and went out to the test department. I was greeted by George Blanchard and he had me sit down at a bench and start reading a manual on the 200A or B oscillator and said, "Start getting acquainted with this." Pretty soon he came back pushing a tool dolly and I was impressed because the tool dolly had my name on it already. I thought, "Boy, this is a class operation."

|

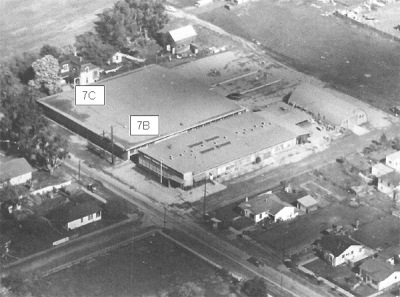

When I hired on in 1952, I worked in the new "concrete" building 7B, which had just been constructed adjacent to the Redwood building (middle of picture). The WWII Quonset building is upper right. In those years, Page Mill Rd (foreground) led to a railroad overcrossing, at the upper left corner. |

I sat there for a little while and George came back and said, "You know anything about microwave?" I said, "Not much," because that was the truth and he said, "Just the guy I'm looking for." He took me over to the microwave test department, which was over in the first concrete building, against the windows, and introduced me to Don Broderick. This was called Bldg 7B, the Redwood Building was 7A. Don was supervising that test line and here were all these people working on microwave components, which we called "plumbing," and which I really knew very little about.

It wasn't very long, with some instruction from Don, until I was sitting there testing microwave equipment like a pro, so I had to start doing some technical homework. Keith Hunton was in charge of all of the microwave testing. Broderick reported to Hunton which was a bit strange, since Keith was still in the lab.

Our main microwave product line was based on world-class signal generators, HP 614, 608 and the 616 series. Keith was a great help to me, as were Don and the other people working there. Keith gave us in production a whole seminar to refresh and teach us about microwave theory. He went through Maxwell's equations and took a lot of time with the test people. So we were doing all the microwave plumbing-wave meters, directional couplers, slotted line carriages, all of which supported customer test assemblies. (HP had purchased much of the plumbing line from Varian a few years earlier and had been improving the line and adding to it since.)

We were in the critical path for the new 624 Microwave Test Set, which was intended for the microwave links that ATT was building across the country, for communications and TV. This made it a critical instrument project. It had a wave meter (which was based on a physical micrometer barrel) sticking out of the front panel. It had a precision microwave attenuator inside, to control the output power of the klystron tube. The attenuator cards were made back in the machine shop. Somebody had set up a conveyor belt that dipped these attentuator cards in this goo which contained a ferrite powder which absorbed microwave signals. Unfortunately, there were no two cards alike.

We would have to individually calibrate the dial on these attenuators. So we'd do that and they were not allowed to have much of a mismatch to the system. They had a standing wave-ratio spec, but we really had a difficult time meeting that spec. That led to the first time I ever met Dave Packard. I was sitting at my bench with a whole bunch of these attenuators that I'd rejected-I don't know how many-and obviously we were holding up the production line somewhere. I became aware of this great big guy standing beside me-bear in mind I had only been at HP maybe a couple of months and had not met him.

He watched for a while and pretty soon he dragged up a stool and he said, "Let me try that." I was calibrating these attenuators, and I was also measuring the SWR spec. He tried two or three of them and they didn't test very well for him either. But that's the first time I met Dave Packard. He was there, typically, with his sleeves rolled up and he wanted to see for himself. There were a couple of the pieces he thought we could fudge a little bit on and get those out the door, but it was very marginal. He said, "We ought to just ship only those," but he got the message that their production consistency was really bad. He got the engineer to go back and look at the card process. The cards were the basic trouble. If the coating on the card was too thick or too thin, you didn't get the resistance you needed. And you'd get a standing wave ratio that was wrong. But that's the way we improved parts and processes, with the test line finding problems, and the lab solving them.

In addition, the directional couplers were fairly new. There was the old coupler design that looked like a cross in a line of microwave products that that we'd bought from Varian. For obvious reasons, they were called "cross-guide" couplers. But there was a new design for a new product, called the multi-hole coupler. The design math had been done by Frank Barnett II and Hewlett. So we had these new couplers to test, and they had a fancy load in them, a pyramid-shaped poly-iron load. It was cast out of epoxy and powdered iron. These components had a sort of "black magic" to their operation. For example, on the couplers, we all learned how to hit the soft brass waveguide with a hammer, just right to modify the internal reflections to meet the specs. We learned where to file parts to meet specs. That was a different kind of electronics, believe you me, not subject to complex design rules.

A roster of early production names

Edna McLain was there, calibrating wave meters, part time while she was still at Stanford, getting her engineering degree. Jane Stone was another early woman technician, who would come in and work on testing wavemeters as well. Paul Gobin joined us as a test engineer at about the same time as I did.

I made a whole list of names of people I worked with there. In microwave test, in addition to Hunton and Broderick, there was Jane Stone, Paul Gobin, Jasper Manetti (who was a genius at assembling attenuators and loads and that kind of thing) and Dick Stone. His specialty was putting together these microwave slotted-line carriages that we were building. If you didn't get all the set screws just right, the detector in the microwave carriage would run up and down rather than linearly horizontal. Dorothy Piggot and Carmel Ryerson were working opposite us building RF cables. I got to know a lot of engineers at that time because, more than any time I remember since, engineers were constantly out on the floor chasing various production problems. One guy I remember was Bill Gallagher who had designed crystal detectors. He was always out there. And Dr. Pete Lacy, who soon left with Bill Jarvis and Duane Dunwoodie, to found the Wiltron Corp, a competitor.

Norm Schrock was busy designing the new oscilloscope line. Bruce Wholey, who came to us from the MIT Radiation Lab of WWII, was running the microwave design group. Art Fong came to work about the same time I did, having worked during the war at the same MIT Rad Lab as Wholey. There was Brunton Bauer, Phil Hand, who was doing work on the attenuators, Nick Pappas, and Al Bagley. I didn't know Al until later when I went over to test.

And Cy Elwell, what a character! I don't know how Cy had come to HP, but he was already an old man, seventy or so. I think he was a friend of Packard's. Somehow he got assigned to come out to microwave test and look at everything we were doing. So he went to work on those attenuator cards and microwave loads to improve the test process. He disappeared back in the machine shop and created a whole new conveyor belt and system for making microwave loads and attenuator cards. He vastly improved things and in the process, we got to hear all of his stories about his past.

Elwell had quite a background. He had founded Federal Electric, a very early electronics company. He had had many experiences in the early radio days and he delighted in telling us about them. That was a great experience. We learned of Elwell's contempt for Dr. Lee de Forest. He always was telling us about how de Forest had robbed him of the credit for the audion (an early triode design) tube. De Forest was working for Elwell at the time when he invented it. Elwell really thought he should have gotten some credit, and he probably should have.

Ralph Lee and Ed Porter were around. Machine assembly occupied most of that floor so we had just one row of benches next to the windows and everything else was machine assembly. Harry Taylor was the foreman for machine assembly. Just beyond where Harry hung out, was Dave Pugh, and he had the sub-assembly work. So I got to know those fellows pretty well. Don Peebles and Ray Demere were always running around looking at the quality of stuff. I never did figure out who they worked for - maybe for Ralph Lee.

At noontime some of us would go over to the machine shop and watch the great Dick Arms poker game. I had started at HP at $1.30 an hour and I couldn't believe the amount of money that was crossing the table in those poker games. I thought, "Boy, I don't know how those guys do that on their wages." Swede Wilde was in the game.

|

Kingman card with parts mounted |

I used to go over to the machine shop every time we had a problem with microwave equipment. If there was something out of spec here or there and I'd go over and talk to those guys. Rufe Kingman was around, who became one of the legendary names in production. Rufe invented the automatic machine, which formed a plated brass strip, and inserted the terminal elements into phenolic boards called Kingman boards, for mounting components with wires. They came to be known as Kingman cards for several decades until printed circuit boards came in.

Dave Scott (Scotty) was the guy who did the beet thinner product. This surprised us because Bill and Dave at one time concluded that electronics might be used in the agriculture business. This design was intended to use electronic photo cells to thin out a row crop of beet plants. The beet thinner prototype was sitting out in the back of that building. I don't know what Scotty was doing, but no one was working on the beet thinner. It just happened to be parked out there, but we all got to understand what it was and why.

Bud Eldon was around and John Veteran and John Veteran's brother were there, although I'm not sure what they were doing at that time. Bud had something to do with production control. The engraving room was between the two concrete buildings, run by Gladys Anderson. We had an outside vendor in there-Elmer-a nearly blind man who sold goodies, candy bars, etc., at lunch time and all day long. There was no cafeteria yet.

Jack Goodwin was running one of the lines and Tom Deaver was running some lines. I'm not sure if Goodwin worked for him or Tom worked for Goodwin. Johnny Morton was on one of the lines there. Jack Petrak was in the lab. After I'd been in microwave test for three or four months, Broderick got transferred out of microwave test and all of a sudden I became the supervisor. By that time, the overall test department was around 50 people. Bill Myers was working with Wholey on signal generators. Bob Grimm had started in the lab and was helping on the HP 624 Microwave Test Set.

I got to know some of the people at the regular beer busts, held on site for some occasion. There were also some Friday night gatherings, which were very informal, but well attended. Those were at the old Heidelberg Beer Garden, along El Camino. On Friday night you really got a good turnout. It always amused me that Packard would often show up, and we would always sing the Eddystone Light (Dave's favorite). Johnny Morton was always there and Porter was always there, but not to sing. I found it a marvelous experience, but I know that my wife hated it with a passion. Friday night I'd get home about eight o'clock, eight-thirty, stoned, and how did I ever drive home? There was no designated driver in those days, just "God is my copilot."

By this time in my early career, I thought HP was the greatest place I could ever imagine. Recall that I had done a lot of manual work in my young life, I'd worked for a lumber company and I just couldn't believe how good HP was to its people. Everybody was like one big happy family. I hadn't been there very long when our new daughter came along. Unexpectedly I got this baby blanket from Mrs. Packard. It just floored me. This happened to all new parents, you were so pleased that Lucille Packard knew you by name. I was about the 500th employee when I came to work. The entire company was located in the Redwood building, the Quonset hut and the two concrete buildings.

In those days, new employees could afford a house

In early 1953, we were still in Boulder Creek, living with my inlaws. As soon as we could, we bought a house in Cupertino. I remember that well. We had invested in a small lot over in Ben Lomond, years before, always thinking we were going to build a house there. After I got the job at HP and commuted for about four or five months from Boulder Creek, I realized that was a real drag. This new development of flat-roofed houses, that were not unlike Eichlers, though not as fancy as Eichlers, had opened up in Monte Vista. So we sold the lot in Ben Lomond for $1000, which was enough to make the down payment of $250 on the new place. Hard to believe, but the total house price was $10,850. I got a GI loan and the interest rate was right at four percent. That was the only way to afford a house. We'll never see those times again.

We had to have furniture and had to pay some closing costs and all that sort of thing, so the thousand dollars went into that. This house had three little bedrooms. The whole house was about a thousand to eleven hundred square feet, but it was on a quarter acre lot in an apricot orchard, right up next to Permanente. So I had more apricots than I knew what to do with and, of course, the lot was just bare dirt. But it was a nice commute and there were two HP guys who lived close by. Carl Fricke was one, and we commuted together to HP. We'd drive up Edith Avenue, along the railroad tracks to Fremont and we'd wind around to HP.

I remember the Christmas party tradition. If my memory serves me right, we celebrated eight million dollars in total sales in my first year, 1952. The following year, '53, the goal was ten million and we made ten plus. I do remember my first Christmas party because for a new guy to see, that was something else. Porter brought out his famous wash tub and they mixed up this big batch of bourbon and god knows what else, some creamy junk. But potent!

In those days, as I have mentioned, everybody in test had a rolling tool dolly. The morning of the Christmas party, every tool dolly had a bottle in it. Over in microwave test we didn't have tool dollies. Individuals all came to work with a bottle and put it in a drawer nearby. By noon that place was just jumping, everybody was happy. I just couldn't believe it. They rolled this old piano out in between the two concrete buildings by Elmer's stand and some guy named Johnny Wright played the piano. And I went home from the Christmas party in the afternoon not feeling any pain. Johnny Wright was a tough guy. He had been hired to keep the Teamster's union organizing project from stopping our trucks. He had been a bodyguard, but he loved ragtime piano. I remember that.

Time to leave production test

After I'd been running microwave test for a while, I'd really gotten to know a lot of people and that was a great experience for me. Briefly then, they transferred me over to Blanchard again. They wanted me to get some more experience with testing the rest of the product line. I thought it was about time too. They were grooming me to run the signal generator line. I went over there and started training on signal generators with Don Carmen and some of those folks. But I hadn't been there very long when Carl Mahurin grabbed me. I went to work for Mahurin in '54 and began that great experience.

I started testing microwave signal generators, particularly 614s and 616s and 624s because I was so familiar with the plumbing components in them. That's how I got to know Bruce Wholey fairly well too. Some of the signal generators were cantankerous and you would never know the reason some of them would fail, but they would. So Bruce would come out to help fix those technical problems.

I hadn't been working for Blanchard over in signal generators very long when I got transferred to work for Mahurin in the Service and Training Dept. That was in 1954, just about 2 years after my hiring in. I don't remember that I had much of a choice about it. I got sent over there because he needed help. But when I got there, it wasn't to work on plumbing or on signal generators, which I knew very well. Instead, I went to work on oscillators. So I worked in that group for a time. Some of the people there were Bob Aiken, Pete Dawson and Stu Churchill.

During my early days in microwave test, this man from the sales department used to come through our test lines, taking customers on tours of the plant. He had dark hair and a furrowed brow, and always was wearing a jacket and tie. I'd see him going through and would hear the spiel he was giving, and I thought to myself, "Boy, if I could have a job like that I'd really have it made." Well, that man was Cort Van Rensselaer, of course. I really envied this man who was bringing these customer tours through, and I thought, "Wow, that was really something to be able to do that."

A little later on when we came out with the HP 612A signal generator (400 to 1200 MHz), it had a lot of problems. The oscillator tube and power amplifier were pencil triodes. A pencil triode was the heart of that sig gen and those things were mounted in a tunable cavity. I don't know if customers diddled with them or what, but those things were coming back to the repair center in quantity, to get that pencil triode replaced. Unfortunately the replacement process was quite a tedious task. So it wasn't long before I got to where I could take one apart and put it back together in my sleep.

Not long after that I started in on the HP 524A Frequency Counter repair. Peter Dawson taught me about the 524A, and I had the same experience with it. Its common problem was that someone had blown all the semiconductor diodes. These diodes were a key part of its digital design, because to achieve the 10 MHz counting rates, the diodes were used to limit the voltage swing of the vacuum tube dual triodes in the fastest decade counters. So those things would come back-and I forget how many there were-but there were about fifty diodes in that sucker and we'd have to change them all.

|

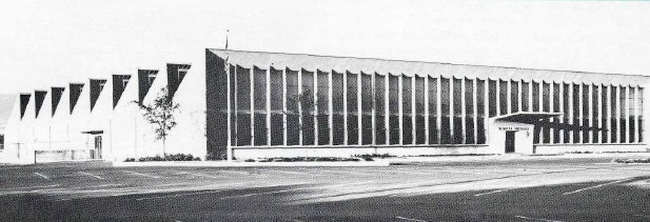

The corporate headquarters of the 1950 period was housed in Building 8, at the corner of Page Mill Rd and Park Blvd. Engineering and Sales was on the ground floor, Mahurin's Service Dept and Training group was in the basement. This was the first of the HP stylized "sawtooth roof" buildings, later used on the 6 buildings in Stanford Industrial Park on the hilltop in 1957. |

One of the reasons that Mahurin's department got tagged with the title, "Charm School," is that Carl's philosophy was that the customer was ALL IMPORTANT. His objective was to instill that crucial impression on us young men, while in his care. One method he used was that in between repairing instruments, we would write letters to customers. Mahurin would hand these letters out and that was when our business training began. We also handled customer call-ins; we'd take turns answering the phone, depending on what the problem was. Carl was an absolute tyrant when it came to how a letter should be written to a customer or how the telephone should be answered. That was some of the best customer-oriented business training I got. He had us go to the class on how to write great letters. We read Strunk and White, "The Elements of Style." He had us go to other classes on how to answer the telephone.

He would bring in outsiders to run these small classes. He was a real stickler for that kind of stuff. We all hated him at the time because he'd make us write letters five or six times before they would pass his inspection. But after a while, I reached the point where he no longer looked at my outgoing letters anymore, and I felt I had really graduated from the Mahurin school.

I had a lot of other experiences during that training time. The Sales Representatives were doing all the selling for HP at that time. Each time a regional office would hire a new salesman, they would send him out to Mahurin for training. That's because their salesmen were supposed to know in detail how things worked. The salesman would report in and we would start him repairing instruments. Then we'd send him over to the test department, and pretty soon he would be very familiar with the inner workings and the application of many different products. They would even answer customer letters, and then they would spend time making repair cost quotations. So by the time they left us and returned to the rep office, they were pretty well trained on Hewlett-Packard products, what they were for, and how to apply them in the customer environment.

I began spending a lot of time in training those people, since the sales force was rapidly expanding. We decided at that time to set up formalized seminars for the sales force. There had been some earlier ones, but I guess it was decided to formalize that and have them fairly often for the new crops of salesmen. We included not only lectures on the theory of modern measurements, but also added real life experiments. HP was preeminent in new measurement technology because our new products often made measurements possible which couldn't be done before. It was important for our salesmen to understand these new techniques.

They might set up a reflectometer to measure frequency response of some component like a diode detector, or take a signal generator and measure the response of some microwave system, as in a customer plant measuring sensitivity of a radar set. I guess I had some skill in writing, so Mahurin had me working on the experiments. I wrote a lot of them for those seminars and then taught in the seminars when the guys would come out. So I got to know a lot of field salesmen.

At the end they would take a quiz, and I wrote a lot of those tests. The reps didn't like the tests very much. But the good part about those seminars was that we had some great dinners and luncheons and some great fellowship in the bars, up and down the El Camino strip afterwards. Soon Mahurin made me the foreman in the service department, so I moved more and more into the paperwork side of the operation - assigning the jobs, pricing the repairs, budgets, etc. - and that's what I did up until 1956.

Toward the end of my service career, Carl also insisted that I ought to learn a lot more about what our customers saw of our products, and he sent me out to final inspection where Ed King and Tim O'Bryant worked. The reason I was there was that in a very short time you got to work on all of the products the company was making, and you learned all the specs. You also learned how to do a quick test of all these, as a final quality check. A rackful of products, already tested and ready to ship, would come from final assembly, and we'd pull one off the shelf, throw it on the bench and test it quickly to the commercial spec, not to the internal spec. After a while, you got to where you knew all the specs and you could do that blindfolded, but you sure learned a lot about all of the instruments. I spent maybe three or four months out there.

Internal vs commercial specs

One of the most important attributes of Hewlett Packard in the field, with customers, was integrity of performance. We had competitors like Tektronix, which was world famous, and renowned for "conservative" specifications. HP had identical objectives, our products always EXCEEDED our written specifications, from our data sheets. One way to achieve this was to insure that the test department had a somewhat tighter performance spec than the commercial data sheet specs. In other words, the instrument had to be better than its spec when it was shipped - by a fair margin.

That was one of the things that customers liked, and depended on. We were pretty tough out there in final inspection. If something was even close to the commercial spec, we might reject it on the spot. At the end of the month, that could create a problem. Ed Porter would come out there, if we were holding up some particular products, and demand to know why. You had better have a good reason. Occasionally, Ed would have us pull the shipping tags on those products, to indicate they'd been shipped, although they were still sitting on the rack. We'd get 'em out the following couple of days. I must admit that this didn't happen often, and we tried not to do it, although if you speak to most commercial companies, this did take place.

As I learned about our product line, I got a certain amount of satisfaction and pride in knowing that the instrument the customer got performed better than its advertised specs. That served me well later on. What it did was give you a lot of confidence when you were dealing with a customer's measurement problem. You knew from the start that the solution to the problem most likely lay elsewhere than his HP instruments.

In those days, we didn't spend very much on advertising. Our best ad was the products already out there in customer hands. It was because of that philosophy, word of mouth really, that sold HP as a "safe buy," and preferred choice. These days they would call it best brand recognition. We had data sheets and a pretty thin annual catalog and that was about it. Advertising in trade magazines was minimal, but would pick up as more competition developed.

My move to marketing, not yet a named department

In 1956, Noel Eldred asked me to come and work for him in the sales department. We didn't have a formal marketing department until the company went public. I think the reason I got to work for Eldred was that he needed some help on some customer sales quotations, and I had done some of them for Mahurin. So Carl loaned me to Noel. I was over there a few days and Eldred came by and said, "Would you rather work over here or for Mahurin?" THAT was not a hard decision. And so began a relationship with Eldred, which, for me, was just great. He became my mentor and was like a father to me.

I reported to Cort Van Rensselaer, who was called the sales manager. I can't remember what we called Noel at that time. But I'm very sure it was not a VP of Marketing, which he later assumed. Cort was U.S. sales manager. I hadn't been there very long when Bill Myers also transferred into sales and the two of us set up HP's first measurement applications department. Customers would write in and would want to know how to solve particular measurement problems using our products. Bill and I would look the problem over and often it had been solved before, for a different customer.

If it was something we hadn't seen before, and we couldn't solve the problem ourselves, we would go to the lab and get somebody there to help us. Bill had been a lab engineer, so he was already pretty knowledgeable. We had the run of HP. We might go out to the service department and "borrow" whatever products we needed, and set up the measurement lashup ourselves and then decide whether it worked and was practical. Then we would write a letter to the customer, or call him on the phone. Most often it wasn't the customer himself; it was a sales rep calling in. Somebody like Bob McVeety would call in and say, "Hey, I'm at Bell Labs (New Jersey) and they've got this problem in measurement and how can we do this?"

It was a marvelous experience, and all of that learning about measurements served me well throughout my entire career. It wasn't too long until Bill and I were absolutely snowed under with work. Ron Whitburn joined us and then we got Bob Aiken as well. Interestingly enough, that little department became a training ground for some future HP executives. It became the future field support organization, really. Engineers like Bill Terry went through, and John Young spent some time there later on. These two just mentioned, are notable names, and were destined to become high level executives later for HP.

This was considered a great training ground. In fact, the rep trainees would spend time with us, as they hired new men for field sales. Often times those men were hired from customer companies, because they were already doing measurement jobs there. We had Dick Kline and Tom Strasser and Rick Weaver come through. Many customers were contractors doing system work for the US government. In those contracts, there were requirements that, when purchasing equipment, they needed to obtain several competing quotations, and were required to choose the lowest price, by law. So we would also work on such quotes, as specified by the sales rep and customer requirements.

Some of my best experiences happened when we would go off to technical road shows with various sales reps, such as Neely. Maybe once a year, Neely management would accumulate new products from HP and other vendors that they sold. They would organize a travelling caravan of station wagons, and a number of sales reps and engineers from the factories. Then they would drive across their territory, setting up in motel meeting rooms or local sales offices, or if a large customer, right in the customer facilities. That was a tremendous experience. And many lifetime friendships developed between factory engineers and salesmen. There were no women sales engineers at that period.

The "Myers Filter," Class B comes to HP

Sometime in this period, an event happened, which wasn't recognized at the time, but which became a long-term improvements in HP product quality. It took place unexpectedly in an off-site talk. Packard felt that once a year, top and middle management needed to withdraw from day to day problems, and meet off-site to discuss past performance and plan future programs. As it happened, Bill Myers had been observing that newly designed products were coming into sales introductions, while they still had reliability problems, which would show up after shipment to our customers.

It was one of those early management meetings, that Myers got up and talked in no uncertain terms, about how our quality wasn't what it used to be. Not every new product had problems, but enough to be worried about, as it affected the reputation of HP, if it continued. So he made a presentation at one of the Sonoma off-site meetings.

Packard and Hewlett and Porter and all the top management were there, of course. And it wasn't very long until Bill was jerked out of our applications department and sent off to work on product quality. He and Edna McLean and perhaps Ray Demere, began a program to formally improve our quality. Since Ralph Lee ran manufacturing, the team reported to him. By that time we had moved to Bldg 9, the sawtooth-roof building at Page Mill Rd and Park Blvd, near the railroad tracks. This was about '57 and the company was in the process of going public.

Bill Myers and his team developed what became known as the "Myers Filter." It was an imaginative plan to subject new products to a rigorous series of environment tests, which could reveal shortcomings in the internal circuits, or in the mechanical layouts. It was intended to prevent such defects from showing up in customer's hands. The test series came to be called the Class B test process. There was some history here, since HP had built several militarized instruments during WWII, intended for ruggedized field operations. This product design was required to meet even more stringent environmental conditions, and those test processes were termed Class A testing.

For Class B performance, every product had to withstand-while operating-a temperature range of -20°F to +55°F, and non-operating from -40°F to +65°F. It had to perform to the specified accuracies in these cold and heat conditions. This test quickly turned up electronic circuitry and components that didn't have enough derating to hold accuracy in some customer environments.

Other tests included vibration and shock tests to make sure that ordinary and extraordinary handling and perhaps dropping in a customer facility would not damage the internal structure and wiring. Vibration tests often revealed that brackets and vacuum tubes had mechanical resonances with the vibration frequency. This could tear apart mounting bolts and sheet metal, and needed new design. There were altitude tests and humidity tests, because often military applications involved remote sites with bad conditions. Extended humidity could result in condensation, and eventual shorting of circuits. Even the shipping containers got tested, the product went into its box, and got dropped 4 feet onto the floor with different sides and corners tested.

It should be noted that the basic electronic component parts we bought for use inside our instruments, all had their own temperature ratings. So our design engineers learned that for an Allen-Bradley resistor that might be rated at 1/2 watt (in open air), it should be used in a circuit such that it never had to dissipate more than let's say 1/4 watt. That way, when it was sitting inside a tiny compartment at +55°F, it would not burn up, or lose accuracy. Vacuum tubes needed ventilation so their performance would not suffer, most often done with a motor fan.

The other management breakthrough which came out of Myer's group was the decision that once the design lab was done with a new product, a formal pilot run of perhaps 10 or 20 instruments would be produced ENTIRELY by the production dept. This forced the lab to have a complete package of accompanying documentation; production drawings, parts lists, test procedures, and usually an instruction manual which would be shipped to the customer with the product. Since the production department was going to have to build all future production, it made sense that the pilot run needed to be the "dress rehearsal" for real production runs, with the lab engineer only permitted to watch.

Al Bagley recalls, "I was in the lab at that time and it's really very interesting because Bill Myers formalized a very tight set of specs. Before anything got out of our lab and was sent to production, it had to meet a formal list of requirements. Boy did we complain. It was tough to get that mindset. We called it the big lead balloon. It was slowing everything down. Yet it became a very important step in HP formally improving its quality. It was a major contribution. And a thankless one for Bill, too."

I lost track of Bill right after that project, but I think he soon was asked to move to the East Coast and take over management of one of the company's new acquisitions, Boonton Radio. I believe Ray Demere took over the quality effort. It was during this time frame, also that the lab guys were working on the HP 150 oscilloscope. Packard came in one night and was inspecting the new prototype, and easily bent the frame of the scope as he checked it for mechanical design. He left a note on that bent frame that said, "Ralph Lee, see me, DP."

The design engineers weren't too fond of Bill Myers and his "Filter." It meant that more time was added to the project management, and worse, if their new baby failed the testing series, that meant they needed to take more time to fix them. These failures of course came at a HIGHLY visible time, when Bill and Dave were watching and waiting for a new product release. But in a couple years, everyone agreed it was a serious improvement to HP brand reliability. And interestingly, as time went on, certain design engineers became recognized for sending new products through the Class B, which never failed. That was almost like getting some military medal for meritorious service.

Springtime in New York City

If it was March, it was the IEEE show in New York City. and it was much like the fashion shows in France. All of the electronic industrial community was there. Everybody at HP vied for the opportunity to go there, to staff the big show. One of my jobs under Eldred was to put together the planning for those shows. I would design our booth layout. There was a guy named Bob Orr, who was doing outside advertising for us in the various trade magazines. But he would also be assigned by Eldred to handle PR. He was the predecessor to Dave Kirby.

He would work with exhibit contractors to get the booth itself put together. My job was to lay out the various instrument displays in the booth. I worked with the guys back in the lab, to set up whatever the demonstration was going to be. So I naturally was always assured that I would go to the big shows. There was the IEEE in New York and then there was another large industry show in Chicago. Right now I can't remember the name of it.

For these big shows, with maybe 100 - 200 HP people attending, from all around the US, planning was a big deal. I'd go back a little early to receive the booth which travelled to New York by truck. I was there to negotiate with the show unions to get the basic booth set up. The union situation in NYC was, to say the least, difficult. What you had to do was agree to pay them. You didn't necessarily need them, or want to hire as many as their shop steward required.

This was particularly true when the show was at the old Armory. Later, the city built a huge and grand convention center over at Central Park South, called the NY Coliseum. The union situation there was even worse. They would insist you hire five guys when two would have done the job. So what we'd do is agree to pay for five guys, or whatever they asked for, and then you'd tell them to just leave us alone. Then our HP guys would unpack everything and set up the booth and get everything going. The union rules stated that carpenters were needed for booth setup, but electricians were needed to move the instruments and plug in the power cords, which was quite ridiculous.

Those were bad labor situations, and so UNLIKE anything we had at HP which of course was non-union. But we had to learn to deal with it, and we did, especially as we returned year after year. Chicago unions were never anything like that. They were babes in the woods when it came to such union practices.

Concurrent with the huge display at the Coliseum, Eldred always planned the annual sales meeting at the Essex House Hotel. This was organized for the benefit of all of the sales rep teams. Those managers used the annual show in New York as a big benefit for their best sales personnel. These reps also sold other manufacturers, and they also had their own sales meetings, so it was quite a week for everyone.

|

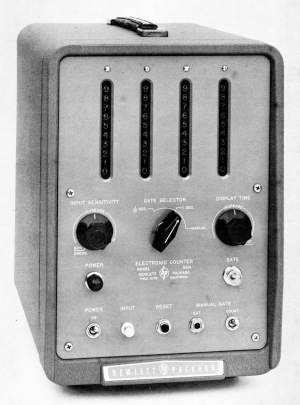

Model 521A Counter |

So there were the formal sales meetings, but there was a lot of person to person contacts after the formal displays were closed. I got to know all those sales principals pretty well. We would all gather in the Editorial Room, a restaurant that happened to be down near the old Armory where the previous shows were held. A man named Gino was running it. And on at least a couple of occasions, for drinking entertainment, we brought an HP 521A Counter, and set it up at Gino's. You could configure this electronic counter for time interval. So we'd all stand around and see how fast we could flip a switch to get the lowest time reading. It was a physical reaction-time test.

That's when we learned that twenty-seven milliseconds was pretty fast for a human being. I don't think the drinking we did had much effect, but certainly it didn't IMPROVE our reaction time.

Another huge benefit for us Californians was that we could go to popular Broadway shows. That was always a big treat. Or we'd go hear some jazz at some of the many night clubs. Packard, I well recall, liked to go hear Dixieland jazz. Al Bagley notes that the Tektronix history book mentions the New York IEEE show, and tells how their Tektronix attendees used to find out where Packard was going, because they knew that's where the best jazz was.

I am first to admit that some of our show doings were not our proudest moments. At HP, there developed an iron-clad rule that you could do whatever you wanted to do at night, but you absolutely had to be on time the next morning when the show opened. This was an inviolable rule of shows. It also applied to our road shows. I must admit that there were times that we'd stay out most of the night and drink all the scotch there was in town. I would always manage to be on time in the morning-somehow. Eldred greatly admired that in my abilities. An iron gut! Sometimes it seemed like I couldn't see, but I'd get to the show early in the morning and get displays turned on and ready to go.

Bagley recalls a time when we were all on a California houseboat vacation. We woke up early one morning, very hung over. It was not in New York City, but Bob Grimm was there and he made the most appropriate remark: "Anyone remember what time the booth is supposed to open?"

I remember some other experiences. One year when the show was still at the Armory, and we had the blizzard of exceptional proportions. That was the year when we were introducing the HP 150 scope. It was acting up and I helped carry that thing, in the snow, from our hotel "repair shop" to the show and back again because you couldn't get a taxi. It was definitely not ready to show, but Packard had insisted, because we needed oscilloscope products to replace the scope product line that Tektronix had cancelled with our reps. But the accelerated design project and early introduction was a bad idea.

Per Johnny Carson: How...cold...was...it? Well, Phil Hand had invented the HP 434A Calorimetric Wattmeter, which depended on a flowing stream of silicone oil, in little 1/8th inch tubing. Now silicone oil is hard to freeze, but the weather was so cold the silicone wouldn't run through the plumbing of that thing. What I mean by that is that if it was outside in a shipping box, moving into the exhibit hall, once it got on the exhibit floor, it wouldn't work until it warmed up.

We spent a LOT of money in New York. It was expected and accepted by management. But there were some funny stories. Art Fong went on one of those shows, and turned in an expense account that was for fifteen cents or something. It was just ridiculous. He hadn't spent a dime. We wondered if he had made arrangements to stay with local family, and we kidded him about that for years.

But the best story about expense accounts was the Palo Alto accountant who monitored all the expense accounts back at HP. His name was Jack Olney, and he had a real tight fisted reputation. You'd bring the expense accounts back from New York City and he'd go over them with a fine-toothed comb and just always contest the big spending. We might have to sometime hide some charges like gratuities to union guys in other categories, like easily approved refreshments (drinks at a bar, before dinner with some sales reps). Jack would crawl all over people if something was wrong. He was always complaining about the amount of money people were spending. For example, a breakfast bill logically shocked Jack, because the grapefruit item was five dollars.

One year-I don't know who put the thought together-Olney was invited to go to the show to see for himself. Packard was certainly part of this thing, because he had heard of all the complaints from his sales troops. Of course, Jack wasn't technical at all but they wanted him to have the experience. Packard had a big dinner for a whole bunch of sales guys in some New York restaurant. The bill came to several thousand dollars. At the end of the dinner, he gave Olney the bill and Jack just about had a heart attack on the spot. He never carried much cash. But that cured him because we didn't get any complaints on New York bills afterwards. So, Packard was taking care of his troops, and enjoyed some of those great experiences with us.

The sales meetings there were rather impressive. We had all of the field sales owners/principals and many of the sales reps. That was a time when engineers from the lab would be invited to come and talk about their new products, which was a perk. They got feedback on what the customers thought. That was a lot of good feedback for HP. Eldred would talk about the year's sales expectations. Hewlett and Packard - mostly Packard - would get up and give everybody a pep talk for the coming year. It was a great experience.

It's interesting, during all my early years at HP, up through that period, I hardly ever saw or got to know Bill Hewlett. For me, he was an almost invisible figure. He would pass through occasionally, nod and say hello, but I never really got to know him. Later on when I was in Europe, I did get to know him very well. Perhaps others had a different experience than I did.

The Sales Reps-strong personalities in action

When I went to work for Eldred, we were in Bldg 9, the first sawtooth-roof building. The lab was in the back of it, sales in the front, and accounting over on the left. Hewlett and Packard had private offices that were in the front corner, overlooking Page Mill Rd. So when Bill Myers left, I became the supervisor of that department in his place. Things began to grow from there. Cort went off to Washington, DC for a technical assignment at the Dept. of Commerce. Bill Jarvis became the guy doing all the customer quotes. Tom Christiansen was doing a lot of government quotations. We began more and more to call our group, Field Sales Support, and by 1957, I was running a very, very busy group.

The applications engineering group was still writing application notes, and had moved. Peter Sherrill had been hired to form a publications department for Eldred. I remember he had an Australian working for him who liked to fly airplanes. The crazy guy's name was Baden Jones, a real character. More and more, our job was in direct support of the field sales reps. HP was growing by leaps and bounds, so we hired more bodies in there, so pretty soon we had to split the country into regions. I became the regional sales manager for everything east of the Mississippi. Dick Reynolds, who came out of the lab where he'd designed the 130 oscilloscope, was given everything west of the Mississippi.

We began to divide the country into smaller pieces of pie because of the support job. Most of the time, when that was going on, I was working a lot on the eastern seaboard, Bivens and Caldwell and Art Lynch, in the South, and those Seven Old Men became my specialty in the Northeast Coast.

The owners and managers of the sales reps were a very interesting mix of characters, from bombastic to thoughtful to highly-technical to arrogant. The term Nine Old Men was applied to an organization, run by a man named Bruce Burlingame, just ahead of my time in sales. He ran a very large post-WWII sales organization which came to be the Eastern Region, from Washington, DC to Western New York State, and Maine. He had been a WWII Colonel, and when he died, and his nine senior people, negotiated with Packard, to divide up the territory and start five independent sales organizations. These were beginning to flourish about the time I came on the scene.

Up in New England, there was Yewell Associates, with Tiny Yewell running that operation. In the greater New York City area, there was the RMC organization. The initials stood for Robert (Bob) Asen, Milt Litchenstein and Charlie Sergeant. In greater Philadelphia and out into Pennsylvania, there was the I. E. Robinson Company, with Ivan Robinson and Leon Levy in charge. Down in the Washington D.C. area was Fred Horman of Horman Associates. In upper New York State, Rube Ryerson ran that organization. There were some other less-senior engineers who had been working for Burlingame, who moved with the new reps, but not as managers. There was Bob McVeety, Rod Foley and a number of other people working who had been part of the Burlingame organization, and some of them took over a few years later when HP bought out all of the old rep owners.

As you moved toward the Midwest, the Chicago area was Crossley Associates. There you would find Frank Waterfall in charge, since Al Crossley was aging. In the Pittsburg-Detroit area was Sy Sterling, who had a strong industrial marketplace. Bivens and Caldwell had everything in the south except Florida. They had North Carolina, Tennessee, Georgia and all those states. In Florida, we had Art Lynch. Art Lynch was the guy they told this story about; Florida was a tough territory because there weren't many customers down there. So Art made it a practice to sign up as many product lines as possible and at one time he had over a hundred lines in his catalog. They told one story about Art, soliciting a "new" company, could he please be their rep? They said, "You already are," and they fired him. He was quite a character. Gene Stiles later took over when Art retired.

We had Earle Lipscomb in Texas and, of course, Norm Neely had most of the west, including New Mexico, all except Washington, Oregon and Idaho. That was the Ron Merritt Company. Ron even covered Hawaii-although there was little business there, other than the military, which mostly bought their HP products centrally. Then a little later on, Pete Lahana took over a rep organization in Colorado that included Utah, Wyoming and so on. Kansas, Missouri, Oklahoma, parts of Nebraska, was Harris-Hansen. Harold Harris had St. Louis as his biggest single market. Altogether, the rep owners were quite a dynamic bunch of men.

For most of the rep organizations, their sales commission was fifteen percent of revenue. The bigger organizations - Neely and perhaps RMC had thirteen percent. That was when I was first working for Eldred. Later on - and I think this must have been '58 - Packard decided to cut the commission. Eldred let the reps know that was going to happen, and they set up a big meeting to negotiate. The rep principals all got together ahead of time, to coordinate their forces. They decided they were going to argue against the cut. The negotiation meeting was held at Rickey's Motel. I can't remember if it was a breakfast or luncheon meeting.

Packard and Eldred and several others of us from HP attended with all these rep principals. One or two of them got up to present their arguments. They stressed the amount of investment they had in assets, and all this kind of value, and suddenly Packard cut them off. My memory is that he first gave them a little lecture on assets and who had the assets and who didn't. Basically what they had was a bunch of salesmen, some offices, and their Brand name, and what he had was a factory. Then he said, "This company has never been run by a committee in the past and we're not going to start now. The commission will be xx%.

So he lowered the commission by edict, not negotiation. I'm not sure of the exact numbers, but I think it went down to around twelve percent for most everybody and stayed there until such time as they were purchased outright. But the interesting thing was there was dead silence among the principals, after Packard's little speech until somebody said, "I guess the meeting is over." That was vintage Packard. And the thing to remember was that all these independent businessmen were personal friends of Dave and Bill. But they knew Dave's decision was final.

The commission reduction came about 1958, about the time we were all becoming painfully aware of how much money we were spending on sales. The field cost of sales was high. That's when we first started talking about CPOD, cost per order dollar. Our finance people were beginning to get some fairly sophisticated measurements of performance. We in sales management were all heavily involved in that because another issue at the time was commission splits between the reps.

Commission splits happened when you had customer companies that went across territorial lines. These were big national companies. You might have a GE operation in Schenectady working on the same project as a GE operation down in Philadelphia, often military contracts. Salesmen from each rep organization would go working on opposite ends of the same project. So you would have the purchase decision being made in one territory, working with one rep, but the purchase was made in another sales region, where little sales persuasion was needed. And yet the purchasing process required sales office work, and financial expertise. The way that was finally worked out, and the way that worked for years is we had the split based on the lines of where the equipment was specified, where the order was placed, and where the shipment was delivered.

So we did have a formula; but it was a constant source of argument, which didn't go away after the reps were bought out. Everyone's income and reputation depended on the total order dollars, so there was a lot of argument. Egos wanted to say, "I did that, I beat quota!"

I'll never forgot Packard's little speech about who really had the investments and the assets. I'm sure the rep principals didn't forget that either. But that was the first crack in the armor of their independence. That would have been late '58, early '59. By that time we had further divided the region sales management in HP marketing. My territory now was basically the eastern region. Rube Ryerson got angry at Eldred over something, and resigned his account. We were all shocked. That was my territory, so I was immediately put on a plane to go back to talk to Rube and see if I could smooth the waters. Rube was very mad-I don't remember the issue-and I could see that further discussions were going to no good if he wanted out. So I reported back to Eldred that he was gone. We had a lot of discussions about what to do and it was decided we would try to find another rep.

I went east and I spent a lot of time in upper New York State interviewing reps. To do this, was interesting, because I did it by calling on customers. I went to people at IBM and Kodak, GE, all the major customers, and asked them to evaluate the other reps in upper New York State. Oshman Associates came out with the greatest number of votes from the customers, so we signed them up. I worked with them, got them on board technically. But about a year later, just about the time I left Eldred's organization, Oshman was killed in a car accident. The company was held together for a little while by his first lieutenant, a man named Roy Smart, but it was unsatisfactory. It was at that time, just as I was leaving domestic sales, that we would start our own HP sales office in upper New York State.

Bill Terry replaced me, running the Eastern Region, when I went to Europe in 1960. After Oshman died, we set up the HP Syracuse office. Bob McVeety went up to Syracuse and ran that operation, reporting to Terry. Bob had been one of the Junior reps who left Burlingame with the Nine Old Men, and had done a superlative job calling on the truly high tech operations of Bell Labs, so he was due for a promotion.

By then, we were managing the four Sales Regions; Eastern, Southern, Midwest and Neely. We had not yet acquired the rep organizations. Dick Reynolds supported Neely. For the life of me I can't remember who had the Midwest and the Southern at that time.

In any complex operation like these independent sales reps, whose performance goals and sales figures were available to all. I can remember the reps good-naturedly arguing about who was doing a good job, or who had an easy territory and who had a rough one? I think it was Bivens and Caldwell, at one point, who claimed you could measure that. For example, they boasted that they made more sales per registered member of the IRE or IEEE than anyone else. To refute that, one of the Neely guys-maybe it was Boniface or Oliverio, pointed out that you could stand on the top of the Hughes Building in Culver City, California, and see more HP customers than any place in the world. There were just an awful lot of wonderful characters out there in the field.

Managing International sales from Palo Alto

Bill Doolittle had been in Europe, since 1959 and had started HPSA, the sales organization. Demere had gone to Germany and started GMBH, along with Fred Schroeder, in order to begin manufacturing there on the Continent. So Doolittle was due to come home in early '61 when school was out. During one trip back to the US, he came over and asked me if I wanted to go to manage HPSA, Europe? With Eldred's blessing, he paid for me to take a trip to see Europe in the winter of 1960. With my family's consultation, I agreed that I would go.

Eldred moved me into Doolittle's operation. By that time the Palo Alto international office was down in Bldg 16, at Hanover and Porter Drive. That's where you found people like Christiansen and the group who did the export licensing and all that kind of complex and legal paperwork. I can't remember who was in charge, but I know Virginia Gross did order processing. Tom Christiansen had all of the licensing and all of the negotiations with Washington on GATT and those export matters. (GATT was the 1947 General Agreement on Tariffs and Trade, established by the European Union of countries.)

Remember that this was a time of "Cold War" with Russia. Our government was highly concerned with technology transfer to the Soviet Bloc. They did this by setting up some very stringent export control rules. This came partly under the Commerce Department and partly under the Defense Department. We were very much cold war oriented, and sophisticated products like HP's could not be exported to a great many countries. The special export license was a very complicated process. It was also subject to serious penalties, both corporate and personal if any attempts were made to circumvent those controls.