The Barney Oliver Amplifier Story

The story began in May 1972, with a memo edited by Dan Lansdon, which started with the following announcement:

"A while back Barney Oliver decided to design a stereo amplifier for his home. This labor of love resulted in a state-of-the-art amplifier with outstanding performance. People at -hp- heard it (or heard about it), wanted one and offered to help make it available to -hp- employees. A cooperative, after-hours "G" job resulted, Chris Clare, Rich Marconi and Ken peterson of Paul Stoft's lab assisted on electrical and mechanical aspects. Paul Rasmuasen of Corporate Industrial Design lent his special talents. Clarence Studley of Stoft's lab finalized the mechanical design. Eileen Martin of HPL did PC layout; Betty Downs of HPL did schematics and artwork. Others, including Tom Osborne, helped in a variety of ways, Barney and his helpers spent many, many ''spare time hours" and we can now take orders for delivery in September.

Without intending to make a sales pitch, I can say that tests in my home against an excellent system convinced me that Barney's amplifier is probably the best stereo amplifier ever built.

If you want a fine quality stereo system, this amplifier offers performance unmatched at two or three times the price, or perhaps at any price"

Another very informative writing about this unusual production of the Hewlett Packard story is the article published in the February 1973 issue of "The Peninsulan". The Peninsulan was a publication by the Corporate Public Relations Services, "For Hewlett-Packard People in Palo Alto, Mountain View, Cupertino, Santa Clara & Sunnyvale". The contents, word for word, and photographs are reproduced below.

Barney Oliver Amplifier:

HP Team Produces Superb Stereo Units (Sorry, All Sold Out)

This is a copy of the article published in "The Peninsulan". February 1973 edition

One of the most unusual projects ever done by employees for employees—the Barney Oliver Amplifier—is nearing completion.

By April or May, the last units of what is believed to be one of the finest stereo amplifiers available at any price will have been delivered to their HP buyers around the world. The units were built with a combination of after-hours volunteer activity and at-cost production.

The project started some two years ago when various people in the company got their first chance to hear the amplifier that HP's vice president of R&D had designed for his own home. How, they asked, could they acquire or build one like it?

With Barney's OK, a team set out to explore that. An offer circulated throughout the company last May produced an amazing 400 orders representing virtually every product and sales division. Price per unit was set at $325.

To meet these orders, a cooperative, after-hours team was formed involving the talents of individuals from many Peninsula divisions. It was decided that although this was not an official HP product, it should be completely assembled and tested to HP standards.

Chris Clare, Rich Marconi, and Ken Peterson of HP Labs assisted on the electronic and mechanical aspects of the amplifier. Assisted by Margo Kauffold, Paul Rasmussen of Corporate Industrial Design lent his special design talents to the overall styling of the front panel and case; HP Labs' Clarence Studley finalized the mechanical design, Eileen Martin did the PC layout, Betty Downs the schematics and artwork, and Tom Jones ordered and expedited the parts. Manufacturing Division provided the sheet metal work plus PC boards and transformers. Harry Wood, packaging engineer of Santa Clara, designed the packing box; and the Santa Clara Division, under the line leadership of Walt Johnson, has been assembling, wiring, and testing the amplifiers on a time-available basis.

First-run deliveries were made before Christmas, but as the amplifier must take a back seat to regular HP production, the last units will not be shipped for a couple of months.

This is not the first "Barney" amplifier. There have been others available in "kit" form, but this is the first to be produced on such a large or complete scale.

Photo above:

BARNEY OLIVER and members of the amplifier team gather around the finished product. Barney is shown standing, while seated from left to right are: Paul Rasmussen, Clarence Studley, Chris Clare, Tom Jones, Eileen Martin, Rich Marconi, and Ken Peterson.

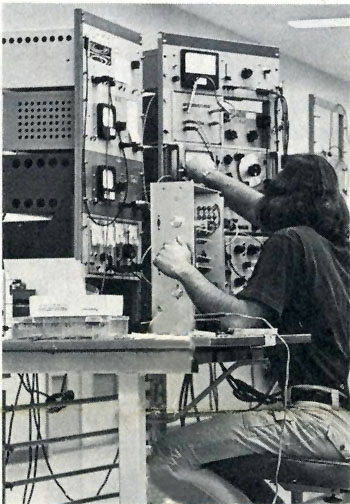

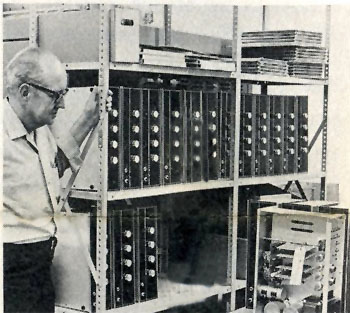

Photo on the left:

TESTING UP TO HP STANDARDS: Larry Scontino is in the process of testing the amplifier to ensure it meets specifications.

The Amplifier Design

In 1972, phonograph records were the dominant music medium and high quality records pressed from masters were starting to be introduced. The amplifier input circuits was designed for the Shure V-15 Type II phono cartridge which was a break-though device and the pinnacle of technology at that time. The amplifier was also optimized for high efficiency speakers such as the JBL L15's, which supposedly Barney had in his home stereo system. It was designed to accurately reproduce a stereo input signal from the very best technology of the day and send it to the very best speakers available.

Among the many particularities in the design of the Barney Oliver amplifier, one is the volume control which is a dual precision step attenuator that sends the input signals to each channel without balance controls. This implying that two perfectly matched amplifier channels follow the input circuitry. The overall look and feel of the inside, as shown below, is very close to the instrumentation technology of the beginning 70s at HP. Even the quality of the service manual published for this 400 units run is very similar to the other HP products of that era.