One of our main objectives in starting this website five years ago was (and still is today) to get in touch with people who have worked at HP from the birth of the company up to today. We are interested in hearing your memories no matter what division or country you worked in, or whether you were in engineering, marketing, finance, administration, or worked in a factory. This is because all of you have contributed to the story of this unique and successful enterprise.

Your memories are a treasure for this website. While product and technology are our main concern, other writings related to the company life are highly welcome, as far as they stay inside the HP Way guidelines.

The contributions made by Jim Hall during his career at HP are illustrated in this chapter. This chapter is a good example of the type of memories we would like to present on this website.

Many thanks Jim for this highly valuable contribution.

Anybody Else ? Please get in touch using the Contact US form.

Jim Hall BiographyJim Hall grew up on a farm near Halifax, Virginia. Listening to the shortwave bands, he discovered ham radio and earned his ham license (W4TVI) at age 14. He received a BSEE from North Carolina State in 1959 and went to work for General Electric Communication Products Division in Lynchburg, Virginia. At GE he was a design engineer for their first and several follow-on solid state point-to-point microwave systems. In 1971 he received an MS in Physics from Lynchburg College. As a GE design engineer, Jim was greatly impressed by the innovation and quality inherent in HP test instruments. In 1972 he received a job offer from HP Microwave Division in Palo Alto and jumped at the chance. At HP, Jim's first project was a thin film 2.6 GHz receiver for NASA's ATS-F experimental satellite TV system. He then managed the HP 8660C Microwave Synthesizer project and investigated Digital Vector Signal Generator technology. In 1976 Jim accepted an offer to move to HP Boise Division (Idaho) and manage development of HP's first laser printer, the 2680A. He remained responsible for all laser/LaserJet R&D up until 1989. At that point, the number of LaserJet projects became so large that high performance LaserJets were spun out into a new division (Network Printer Division) and the remaining Boise Division projects split into two groups (Mid-Range and Personal) with Jim retaining responsibility for Personal LaserJet R&D. A new division focused on Color LaserJet printers was formed 1995 and Jim became R&D lab manager for that group. Then in 1997 he became R&D manager for all LaserJet printers, holding that position until he retired in 2000. Since retiring, Jim enjoys spending more time with his wife (Myrtle) and family (especially the three grandchildren), pleasure travel, electronics projects and ham radio.

|

Foreword by John Minck

If you're making a Top-10 list of inventions that changed history, you'd probably include the internal combustion engine, the transistor, the atom bomb(?), the generic cell phone, the telephone, the PC, among others. But you'd be hard pressed NOT to add the HP LaserJet printer. Its production numbers in 2006 surpassed 100 million. Arguably, the Father of the LaserJet would have to be Jim Hall, of HP's Boise Division. Jim joined the 1972 Microwave Division from GE, Lynchburg, where he worked on microwave communications gear. After several years at MWD, he transferred to the Computer Group Boise Division as it embarked on computer printing products, and began a remarkable leadership quest for the ultimate in personal printing products. Much has been written about the HP Laserjet success, but here is the story direct from the man and his team which made it happen. There were other contributors, including HP Labs, and of course, the Canon laser engine, but the Boise Division should get the kudos for persevering to an amazing and enduring product line. Invention, Indeed!

John Minck

|

HP LaserJet - The Early History, by Jim Hall

Table of Contents:

Why write a LaserJet History? Over the past 15 years, various books and articles have given bits and pieces of HP LaserJet history and dissected the reasons for its market and business success. Most 1,2,3 have been reasonably accurate, while one was mostly inaccurate. Still I don't feel any of them gives the reader a complete understanding of the facts behind HP LaserJet's success. My goal here is to try to give a complete, early (admittedly R&D centric) history 4, plus offer a few thoughts as to why LaserJet continues to be successful after more than 25 years. As you will see, many, many factors came together to develop the remarkable LaserJet story.

Why should I be the one to write a LaserJet history? Mostly because I was the R&D project/section manager for HP's first laser printer (HP 2680A) during most of its development. After that I was R&D section manager for all laser/LaserJet products until 1989 and all Personal LaserJet products until 1995. So I was in the middle of most of the history that follows.

Computers and Printing in the Late 70's and Early 80's

In the late 1970's and early 1980's computers and computer printing was in the stone age compared to today. Operating systems were rudimentary and performance was often lacking. No wireless connections or Internet. Graphics was crude or non-existent and fonts were fixed in size and spacing. WYSIWYG (what-you-see-is-what-you get), color and digital pictures were only dreams in minds of the technically sophisticated. Almost all of what we take for granted today with computers and printing was still the stuff of scientific fiction.

In the mid-70's mainframe computing was starting to fade and the minicomputer market (Digital Equipment, HP, Data General) was exploding. Minicomputers made it possible for even mid-sized companies to finally own a computer. But computers and computer printing remained centralized and behind glass walls. Computer printers utilized impact print technology which had poor print quality and was extremely noisy. Laser xerographic printers costing $500,000 or more had been introduced by IBM and Xerox for mainframe computers but there was nothing comparable for the minicomputer market. There was an opportunity for HP to offer a better printing solution for our rapidly growing HP 3000 minicomputer line.

Then in 1981, IBM introduced their personal computer and the world of computing began an even more dramatic transformation. Having a computer running "killer apps" like Lotus 1-2-3, WordPerfect and MS Word on your very own desk was personally-enabling in a way no one could imagine. But without a printed page, a PC was a bit like a 2-legged stool, something was missing. You could do wonderfully creative work, but in the end, the job was not finished until you could print your results onto a permanent page. The only personal printing solutions available were slow, noisy daisy wheel printers, slower thermal printers requiring expensive, special paper or slow, noisy dot matrix impact printers with poor print quality. This proved to be an even greater printer market opportunity for HP.

The HP Boise Division

In the fall of 1973, the Boise Division was established with Ray Smelek as Division General Manager. The original charter of the division was to design, manufacture and market printers for HP minicomputers (HP 3000, HP 1000). In addition, the division was responsible for manufacturing the HP 7970 tape drive, another HP minicomputer peripheral. At that time it was felt that tape drives were becoming obsolete and there was no need to invest in developing new ones. Therefore Boise Division could use the revenue from the HP 7970 to fund the division but focus all new product development on printers, a growing market and product needed for HP computers.

The first printer Boise Division put into production was the HP 2607A line dot matrix printer, introduced in 1974. Its design and manufacturing rights had been purchased from another company. It was a relatively poor product so Boise Division immediately started the design of a replacement printer (HP 2608A).

The Canon/HP Relationship

The Canon/HP relationship is a key part of LaserJet history. The relationship between the two companies started while HP was working with Yokogawa Electric Works to form the YHP Division in Japan as our entry into the Asian market. In the early 1960's, Bill Hewlett met with various Japanese companies to develop a better understanding of HP's Japanese YHP partner. In those meetings, Bill Hewlett became friends with Dr. Takeshi Mitarai, the person who resurrected Canon after WWII and became its first post-WWII president. Both companies were high tech and known for empowering young engineers to quickly develop innovative products. In addition, Dr. Mitarai was a medical doctor as was Bill Hewlett's father.

Several years later, in an interesting side story, when Dr. Mitarai's son (Hajime Mitarai) applied to Stanford University to pursue a PhD in electrical engineering, he was at first turned down. Dr. Mitarai told this to YHP president Ken Sasaoka, who in turn phoned Bill Hewlett to see if he could find out why. When Hewlett inquired, the responsible Stanford dean couldn't understand why Hajime hadn't been admitted, and accepted him on the spot for the PhD program. After obtaining his PhD, Hajime worked in the US semiconductor industry for a couple of years before returning to Japan to head up Canon's Central Research Laboratory (CRL). Interestingly, Canon's CRL was where the Canon's laser printer was developed and "mothered" for several years before finally becoming a successful commercial product line within the company.

HP's First Laser Printer - HP 2680A (EPOC)

In the mid 1970's Canon developed a prototype laser printer based on their NP5000 45 page-per-minute (ppm), dry toner copier and demonstrated it at the fall 1975 National Computer Conference (NCC). They were hoping to find a partner to bring their technology to market. At that time John Young was HP's Executive VP for computer, instrument and component groups and was at NCC. So when Canon asked Bill Hewlett to look at their laser printer, Hewlett had Young do just that. Young was intrigued by the product and quickly involved Hewlett and Paul Ely (Computer Group Manager). Ely contacted Ray Smelek in Boise. After reviewing the product, they all supported buying the technology from Canon.

Bill Hewlett put together a team to purchase the technology. Don Hammond of HP Labs led the team. Other members were John Chognard (HP General Counsel), Jim Boyden (HP Labs) and Jim Barnes (Boise Division R&D Manager). After two or three days in Japan, viewing the prototype and negotiating, Hammond and team were able to work out an agreement with Canon. This agreement, launching HP into laser printing, was another example of Bill Hewlett's vision and willingness to gamble on new technology and business opportunities.

Design of HP's first laser printer commenced with the formation of a Boise Division R&D design team in early 1976. I was the initial project manager. When Ray Smelek and Jim Barnes interviewed me for the job I told them I didn't know anything about laser printers (My background was in microwave communications (13 years at GE) and instrumentation (4 years at HP)). They said: "Don't worry, no one else in HP does either." I was gratified and yet somewhat intrigued when they hired me anyway.

Our project was code named EPOC (Electrophoto-graphic Printer On Computer), a play on "epoch" or new era of printing (It is traditional within HP to let the R&D team pick the code name for their project.). The actual product model number became the HP 2680A. Our vision (and the one that convinced Hewlett and team to invest in the technology) was to commercialize the Canon NP5000 copier based prototype by simply adding an HP print controller and laser optics. However it turned out this was only the tip of the iceberg as far as the amount of effort ahead of us.

When we tested Canon's prototype in the summer of 1976 we found its MPBF (mean pages between failures) was only around 250 printed pages. This was clearly unacceptable for a computer peripheral. Even if we improved the MPBF by a factor of 10 or even 100 it would still be too troublesome and expensive to maintain. Part of the problem was that HP mostly employed engineers to support our mini-computers and peripherals. They were expensive ($100 per hour) and mostly experts in computers, not the technologies used in a laser printer (mechanics, high voltage electrostatics and lasers).

Service wasn't as big a problem for companies in the copier business (like Canon) who employed less expensive service technicians with their training focused on copier technology. However it was sure to be a computer-room stopper for HP or anyone trying to support both computers and laser printers with the same service staff. For a successful HP minicomputer laser printer, we felt we needed to achieve an MPBF of at least 100,000 pages. This drive for reliability was founded on business reality but also came naturally from HP's historical obsession with quality in our instruments. Meeting our reliability goal required a complete redesign of Canon's prototype concept and implementation of an extensive MPBF testing program.

|

Cover of June 1982, HP Journal Courtesy of the Hewlett-Packard Company |

For EPOC design details, look at the HP Journals of June and July 1982. The June issue includes a good description of the laser printing process. LaserJet products were able to simplify some steps but the basic process has remained the same. For on-line copies of these HP Journal articles, click-in link above or in the picture on the right.

When you read the HP Journal articles, you will gain some appreciation for the size and complexity of the EPOC project. For example, the completed product had some 10,000 parts. 3,500 of these were designed specifically for EPOC. Not only did we have to completely redesign Canon's concept, we had to conquer multiple technologies and design new solutions encompassing many dimensions of physics, mechanics, electronics, computers, software and systems. One particularly daunting challenge was the printer controller/formatter which had to support EPOC's 45 ppm print speed. Jim Langley designed an innovative "linked list" bit slice microprocessor architecture and programming language that solved this problem.

|

HP 2680A Laser Printing System |

The HP Labs (Palo Alto) team and the HP 3000 (Cupertino) software division helped us a lot. However most of the design responsibility for this huge undertaking still resided with the young, relatively inexperienced group of engineers in Boise. The whole design team rose to the challenge, driven by a fear that either IBM or Xerox would scoop us with a comparable product. Everyone was extremely motivated and felt proud to be part of making a breakthrough product like EPOC successful.

In early 1980, I became Boise Division R&D manager and Bill Robison assumed responsibility for the EPOC project. He successfully released EPOC to manufacturing in late 1980 and on December 7, 1980, after almost 4 years of development, we finally introduced the HP 2680A Laser Printing System. It was extremely reliable (many machines demonstrated an MPBF approaching a million pages), fast at 45 ppm, had excellent print quality and supported multiple type faces and complex graphics. It worked seamlessly with the HP 3000 and included software which allowed users to design their own custom fonts, logos and electronic form overlays. Nothing on the market came close to matching the price/performance or features of the HP 2680A. The only problem was that it only worked with the HP 3000 minicomputer and sold for almost as much ($120,000).

To give you a better feel for the HP 2680A's place in HP's laser printer history, here's what the Boise Division marketing manager had to say about it on the tenth anniversary of its market introduction (By this time LaserJet had established a dominant worldwide market position.):

"Friday, December 7, 1990. Ten years ago today, HP introduced its first laser printer, the HP 2680A Laser Printing System. We had a "pool" in marketing on how many we would sell in that first month; the forecast was 75, actual sales were zero. We also sold zero in January and in February. Finally in March we sold our first unit to a company in Washington D.C. This was the struggling beginning of the laser printer revolution within HP. A sequence of events that have lifted us to a leadership position in the world. The HP 2680A, from this humble beginning, is still part of our product line. It has become a cornerstone of many HP 3000 data centers and the source of many innovative ideas."

So the HP2680A was a great technical achievement and a solid product (It stayed in the HP product line for 12 years and we sold approximately 1200 units) but it didn't become the huge market success we had hoped.

The revolutionary HP 2680A made many contributions to our eventual LaserJet successes.

- During its development we established a strong working relationship with Canon, including Hajime Mitarai, Takashi Kitamura, Junji Ichikawa and several others who became key members of the Canon management team during the early LaserJet years and into the late '90s.

- We learned about laser printer technology from the inside out.

- The EPOC controller/formatter taught us a lot about controller design and printer control languages. We learned about the design and use of high quality proportional fonts.

- We internalized the value customers placed on the ability to mix multiple fonts and graphics on the same page.

In spite of being disappointed by the lack of early market success with the HP 2680A, we (Boise Division) were still convinced that laser printing was the future for high speed, high quality printing. However we also internalized that only companies (like Canon) who could leverage their huge copier investments, "know how", patents, manufacturing capability, etc. could be successful in building laser print engines. HP was just too far behind and lacked the resources to realistically catch up. Therefore our "next generation" strategy focused on buying a smaller, lower cost, lower speed laser print engine from one of the copier companies. This would give us the right price/performance to match the needs of our HP minicomputers (Remember this was the early '80s and the PC market was in its infancy.).

Canon was easily our #1 choice to supply our next generation printer. However the only print engine they could offer was the LBP-10. The LBP-10 was a 10 ppm, solid state laser, liquid toner print engine that Canon had introduced in 1979. The price/performance was acceptable, the reliability good but the liquid toner was a killer. Paper coming out of the printer was saturated with the liquid (which smelled like kerosene) that carried the toner. Besides smelling bad the liquid was flammable and Underwriter Laboratories would not approve its use in a computer room environment. (This seemed to be a strange anomaly in the UL regulations. They allowed flammable chemicals like kerosene in the office but not in computer rooms!). I kept insisting that Canon needed to come up with a "dry toner" print engine. Canon kept insisting that HP should buy the LBP-10. Finally it became obvious that we would have to use a different engine supplier.

HP buys our Second Laser Print Engine from Ricoh

During 1981 and early 1982 I traveled throughout Japan in search of a suitable laser print engine we could purchase. Finally I chose Ricoh, who had almost completed development of a desktop 12 ppm laser printer (engine and controller), as our supplier.

We named this HP project "Bonsai" which was the smallest tree we could imagine (Admittedly it's a bit of a stretch, paper is made from trees, paper is what comes out of a printer). Side note: The Ricoh folks were upset when they heard the project name we had chosen. Turns out that depending on how you pronounce Bonsai, it can come out as the tree or the cry "banzai!" that had unpleasant WWII implications. We intended the former but pronounced it like the latter. After explanations, everything turned out OK! Another lesson for us in Japanese culture!

Mr. Kitamura headed Canon's Laser Beam Printer Business Division at this time. Although his group utilized much of Canon's copier technology and know-how, it was a completely separate business from copiers. He was devastated when I told him of HP's decision to go with Ricoh. Ricoh was Canon's largest Japanese copier competitor and our choice resulted in a major loss of face for Canon. Mr. Kitamura railed against HP's decision all through dinner the night I told him, repeatedly telling me that HP would deeply regret our decision. This was clearly a low point in the Canon/HP relationship!

|

HP 2687A Desktop Laser Printer Courtesy of the HP Computer Museum4 |

HP introduced the Bonsai laser printer (HP 2687A) in 1983. Although desktop and dramatically less expensive, it turned out to still be too expensive ($12,800) for its 12ppm performance and the reliability proved to be poor. The technology used in the printer was just too complex to have a reasonable chance of meeting our reliability goals or customer expectations. So unfortunately, once again we didn't achieve any serious market success.

Printer Command Language (PCL)

By the early 1980s Boise Division had active projects for a whole family of computer printers. These included daisy wheel, serial dot matrix, line dot matrix and laser printers. Each product tended to have its own unique set of computer commands for printing. This meant that each of the host computer systems had to have different software to control each of the multiple printers. As a result, the effort to provide the necessary system software was growing exponentially. Clearly, something had to be done.

Von Hansen (Formatter Project Manager) and his team in Boise Division developed a uniform Printer Command Language (PCL) for all our printer products. The language needed to be scalable since at one end, simple products like our serial dot matrix printers had a limited set of features while on the other end, laser printers had a very broad set of features. For that reason PCL was developed to have a range of capabilities. PCL 1 for the simplest printers, with higher levels of PCL having greater capability for printers with a wider range of printing features.

A key attribute of PCL was that each higher level of the language was a true superset of all lower levels. For example if you sent out PCL1 commands, all PCL printers (PCL1, PCL2, PCLn) would successfully print that information, just the way a PCL1 printer would. You might not be able exercise some higher level features but at least you could successfully print. If you sent out PCL2 commands, all PCL2 and higher printers would print your information just like a PCL2 printer and so forth.

This PCL approach allowed us to implement PCL2 in Bonsai, then move to PCL3 for the first LaserJet, then PCL4 for LaserJet II, etc. System software developed for Bonsai worked on all future LaserJets. Software developed for the first LaserJet worked on all later LaserJets and so forth. If you had a later generation PCL printer and software for an earlier generation PCL printer, you were still OK so long as you only needed the older set of PCL features.

So PCL had three key strategic advantages for LaserJet:

- It allowed us to grow the capability of PCL in step with the decreasing cost of printer memory and processing power. This let us to keep costs low in the early days when customers were happy with limited functionality but to grow functionality as semiconductor costs came down.

- It let HP spread out our PCL development investment over multiple years allowing us to add functionality one step at a time.

- It maintained customer satisfaction with computer software. For example, if a customer got a new printer with PCL4 capability but had computer software supporting only PCL3, he could still print with all PCL3 features. Later when PCL4 software was available he could take advantage of his new printer's new features. Customers really liked this "backward compatibility" feature of PCL.

Bonsai was the first HP laser printer to use PCL. So although Bonsai wasn't very successful in the market, it provided us the requirement and platform to develop PCL2 and 300 dots per inch (dpi) font families (EPOC was only 180dpi). We also developed print engine, environmental and regulatory specifications for Bonsai and utilized our experience from the HP 2680A to set goals and participate in print engine testing and qualification. These added to the building blocks at our disposal for the fast track LaserJet product that followed!

Back to Canon for our Third Laser Printer Product

On April 7, 1983 Canon's Mr. Kitamura came to Boise and (finally) demonstrated their dry toner print engine (CX). Not only did it use dry toner and a solid state laser leveraged from the high volumes used in CD players, but most importantly, it utilized the "all-in-one" cartridge concept Canon had recently invented and implemented for the first time in their desktop personal copier (PC-20), introduced in 1982. The concept was to package the printer toner with all the other components that tended to wear out and require service (e.g. photoconductive drum, charging and cleaning systems) in a customer replaceable cartridge. Thus when the toner was depleted, the customer plugged in a new cartridge and in effect had an almost new printer. The cartridge tends to be called the "toner cartridge" since the customers signal to change the cartridge is when the toner runs out. However this name isn't a good representation of the other major engine components contained in a cartridge. For more detail see the Canon video showing how laser printing works with the "all-in-one" cartridge at:

http://www.canon.com/technology/canon_tech/category/output.html#lp

Click on: "Special features of Canon products, All-in-one-cartridges".

Canon sold the CX engine to several other companies including Apple. We beat Apple to market with the CX engine by almost a year and at a price much lower than their product. Canon also sold the CX to a few small companies but they didn't have the volumes to compete and quickly dropped out of the market. I imagine Canon also offered the CX to IBM and maybe even Xerox but evidently neither of them was interested.

Canon's "all-in-one" toner cartridge was a breakthrough concept, finally achieving "electronics like" reliability with a simple, straightforward design. In addition, since the CX print engine was largely leveraged from Canon's hugely successful, high volume personal copier, the manufacturing cost was relatively low. We were all tremendously excited when we saw the printer. We felt we finally had the product and partner we had wanted all along!

We chose Sprout as our project name for the first LaserJet. What's a "tree" smaller than a Bonsai? Of course, just a Sprout!

Schedule and trade-offs

When Canon visited us in April 1983, they told us they would be ready to begin mass production of the CX engine by February 1984. We were determined to match Canon's schedule for our HP product. This meant we would have had only ten months to develop a controller for the product. For that reason, we elected to use the controller Canon had already developed for their CX based product.

PCL (again)

For the print controller, there was much internal pressure to just emulate the Diablo 630 Daisy Wheel Printer (good text quality) or the Epson Dot Matrix Printer (good graphics) for Sprout since both of those products already had good software support across the industry. However, based on our HP 2680A experience, we knew business users wanted to print mixed text and graphics. For that reason we decided to use HP PCL since it had that capability plus all the other advantages mentioned earlier. So Von Hanson and his team worked with Canon to specify and implement PCL3 in their controller for Sprout.

PCL3 offered all the features early PC customers could realistically utilize (especially since at that time PCs lacked a graphical user interface) at a much lower price than the much more complex page description language (Postscript) chosen by Apple. By using our already largely-developed PCL, we were able to deliver LaserJet for a street price about $1,000 less and almost a year before Apple's CX based product.

Software support was critical to making PCL and LaserJet successful. One opportunity came on an airplane departing the Softcon computer software show in New Orleans in February 1984. Von Hansen and Roger Archibald "just happened" to be seated on the plane beside Bill Gates of Microsoft. They told Gates about HP's exciting new laser printer and how it was the ideal output device for Microsoft products like Word and Excel. We were never sure how much this helped to get Microsoft support for LaserJet and PCL but it surely didn't hurt! How is THAT for serendipity?

A few weeks later Von carried a LaserJet prototype to Microsoft to solicit their software support. Initially the Microsoft folks gave the HP team a rather cool reception. But then Von took LaserJet out of its box and printed some demo pages. This got the Microsoft people really excited and they immediately called for their managers to come look at the printer. From that point forward, Microsoft tended to offer good software support for LaserJet and other PCL products.

In addition to Microsoft, we worked with other major independent software vendors (ISVs) to ensure excellent application software support for PCL. However during development of the first LaserJet we didn't have enough resources to do much. Later, Janet Buschert in the lab and then Cathy Lyons in marketing led major efforts that dramatically grew PCL application software support.

Fonts were a challenge for the first LaserJets. Semiconductor memory was very expensive and customer font requirements very fragmented. For those reasons, we elected to offer a limited number of "built-in" fonts and supply the rest in optional font cartridges. This satisfied mainstream users, kept the printer cost low and still gave customers a way to satisfy their special font requirements. Font cartridges (and fonts) became another responsibility for Janet Buschert. Through her efforts, this soon became a major business in its own right with more than 25 different cartridges at prices ranging from $150 to $330 each. It remained a good business for us into the early '90s when Microsoft started bundling fonts with their Windows operating system.

When Microsoft started bundling fonts with Windows, they basically gave them away. This was a huge advantage to HP in that it mostly solved our font problem and made WYSIWYG much better by ensuring matching screen and printer fonts.

Piggybacking on the Dealer Demos

Late in 1983 HP instigated a major push to participate in the PC market. A key part of this strategy involved development of a PC dealer channel to sell the new HP 150 Touch Screen PC (to be introduced in May 1984 along with LaserJet). The computer part of HP had the management support, money, resources and (hopefully) the PC to drive development of this channel. As the PC market exploded, several individuals associated with the LaserJet development (Roger Archibald, Von Hansen and Alan Armstrong) sensed that (just maybe) there could be a PC market for LaserJet. So we begged the HP 150 marketing folks to let us go along with them when they demonstrated their product to the major PC dealers. Finally they agreed to let us go with them to visit a few of the dealers but reserved the majority of time to demo the HP 150 (e.g. 1 ~ 1.5 hours) while letting us have 10 or 15 minutes at the end to demonstrate LaserJet.

|

HP LaserJet |

The dealer visits were a real eye opener for Boise Division. Typically the meeting started with dealer upper management in attendance. As the HP 150 demonstration dragged on, most of the dealer managers left and only a few subordinates stayed. When the LaserJet demo started, a subordinate would suddenly say "Wait a minute" and dash out of the room. Soon they returned with their managers to watch the LaserJet demo. Needless to stay, all of the dealers we visited wanted to carry the LaserJet in their stores and thought it would be a good seller.

The HP PC Division still hesitated to let Boise Division sell LaserJet through the dealer channel. They thought it would defocus efforts to sell HP PCs. But after repeated urging by Roger Archibald they finally gave in at the last minute. Access to the PC dealer channel proved to be a key contributor to LaserJet's market success. It quickly proved to be the overwhelming vehicle for LaserJet sales.

Dealer visits plus the PC Division's agreement to let us use "their" dealer channel, convinced those of us in Boise Division that the LaserJet market was likely to be much bigger than just that required for HP minicomputers. This in turn gave us the confidence to forecast higher sales volumes when we priced the product. Paul Ely (Dick Hackborn's 4 boss) was the person who bought into our sales volume vision and gave the final OK to price the first LaserJet at an aggressive $3,495.

When we began development of Sprout (spring 1983), our market focus was still as a peripheral for HP minicomputers. HP's sales channel was largely direct sales and we were just beginning to develop a dealer channel. In addition, we estimated the first LaserJet would need to be priced at between $3,500 and $4,000. This was about equal to what an IBM PC sold for. PC sales were beginning to ramp up but we guessed that few customers would be willing to pay so much for a printer to go with their PC. We thought 1/2 or 1/3 of the cost of a PC was more likely what customers would expect.

Of course our prediction of customer expectations turned out to be wrong. We discovered that business customers were willing to pay much more for the break through print capability Sprout offered than we had imagined.

Because of our early focus on HP minicomputers as our market, the first LaserJet was designed with only a serial interface. By the time we knew we could sell through the dealer channel and that business PC customers might pay what a LaserJet would sell for, it was too late to change the design and add a parallel interface. We corrected this shortcoming in LaserJet+.

Naming LaserJet

In the natural order of things, the first LaserJet should have been the HP 2686A. HP had always named our products by their model number so why should this product be different? Our Boise marketing people heard that the first HP thermal inkjet printer was going to be called "ThinkJet" (for "THermal INK JET) so they said "That's catchy. Why don't we name our product the "LaserJet"?" We lab engineers thought this was a dumb idea. Our printer had a laser but it certainly didn't have a "JET". Fortunately marketing prevailed and LaserJet was born!

LaserJet Time to Market

We couldn't have achieved the short schedule for Sprout without our two earlier "failures." With the HP 2680A we established a strong working relationship with Canon. We also learned about the features customers wanted, fonts and the technologies involved in laser printing. With Bonsai we developed 300dpi laser fonts, implemented PCL2 and determined that significant HP engine testing was required to identify and cure failure modes. We had also developed the engine, environmental and regulatory specifications necessary for the product to meet HP's worldwide market requirements.

We were determined to (and did) make the LaserJet's schedule match that of Canon's print engine and product. So it turned out that we were the first company to have a CX engine based product in the PC dealer channel in the USA and Europe. Canon's product had some presence but it was small compared to HP. Canon's marketing strength was more with copier dealers and not the newly emerging PC dealers.

Reliability

HP played a significant role with Canon in the test-fail-fix process of product development. Canon supplied HP with early prototypes and HP ran them until they failed. Of course Canon ran a similar process in parallel with HP. However we often found failure modes and usability problems Canon didn't see (or recognize) in their testing. About 15% or 20% of the failures found during the design process were unique to HP's testing. When problems were found, fixes were incorporated in later prototypes. Then we did more testing, failures and problems were analyzed and more fixes incorporated. This process went on throughout the development cycle. Together with Canon we discovered that joint testing resulted in a customer friendly product with superior reliability.

Not Everyone was a LaserJet Booster

There were forces working against LaserJet's initial (and longer term) success:

Limited resources and time - In early 1982 Dick Hackborn5 recruited a new R&D manager for Boise Division. The new manager changed our focus from laser printing to an investigation of high speed thermal ink jet TIJ) printing. As a result, by the middle of 1983 Boise Division had 5 engineers working to specify/qualify the Sprout engine and 15 engineers working on high speed TIJ technology. This reflected the feeling by much of upper management at this point in time. They weren't confident in LaserJet and believed TIJ had a good shot at replacing it in the midrange and high end markets. That still hasn't happened, twenty-five years later.

Besides limited resources, we had less than ten months between the time Canon showed us the CX prototype and the date Canon would start production of the print engine. In spite of limited support, we were still able to match Canon's engine schedule and full LaserJet production began in February 1984.

Historically HP was a vertically integrated company. Corporate culture tended to believe HP had to control the technology used in our products. So from the beginning, HP upper management was inclined to discourage investment in laser printers based on a purchased engine and there was certainly some logic in that historical perspective. They were convinced the engine supplier would eventually take the market away from us with their own product using the same engine. This belief was still alive even after LaserJet was wildly successful and we had already sold several million units.

For example I remember Dick Hackborn interacting with us during a quarterly review when we were demonstrating the LaserJet II prototype. I expressed our excitement about the product and our belief that its market potential was even greater than the first LaserJet. We also explained our short schedule and need for additional resources to stay on track. Dick's response was something like: "It (LaserJet business) looks OK now but don't get used to it because it won't last." Everyone who heard this received it like a dash of cold water. In spite of this, the project team wasn't deterred and if anything worked even harder to make LaserJet II a success.

Another example was around 1990 when HP's CEO told HP Labs they shouldn't support LaserJet with their research because it was probably not a sustainable business.

Finally, in January 1984 Boise Division General Manager Ray Smelek attended the annual HP general managers meeting in Napa, California. He told HP's top leaders from around the world that Boise Division was ready to launch a remarkable product in four months and we were convinced we could potentially sell as many as fifty thousand a year. Ray was almost laughed off the podium. Everyone in the room knew HP Computer Group had never sold fifty thousand of anything. Clearly hardly anyone in HP believed in laser printing or LaserJet. Only Ray and a small group of us in Boise Division kept the faith.

Successful LaserJet Market Introduction

We introduced the HP LaserJet on schedule at the National Computer Conference (COMDEX) in May 1984. It was a huge success at that show with long lines of attendees waiting to look at the LaserJet and find out how they could buy one. In May we received orders for about 1500 printers. December 1984 orders were for almost 8,000 printers. We ended up shipping 250,000 over its life.

LaserJet Follow-On Products Offer "More for Less"

It is with considerable pride that we can look at the following list of follow-on LaserJets. Each built on the success of the first LaserJet by continually offering "more for less". New product generations offered more features and capability for less cost, obsoleting the previous generation. This classic business strategy was implemented to near perfection with the early LaserJet products.

New capabilities are highlighted in Bold Italics. In general once a new capability was incorporated into a product, it was incorporated in all subsequent products. For example LJ II and all following products had correct order (face down) output, LJ IIP and all following products had "No Ozone" print engines, PCL was continually enhanced from product to product with higher levels of functionality. This gave customers "more" capability with each new product:

- LaserJet: 8 ppm, 300 dpi, $3,495, Spring 1984. Price reduced to $2,995, September 1985.

- LaserJet+: LaserJet with more formatting features, memory, fonts and a Centronics parallel interface. 8 ppm, 300 dpi, $3,995, September 1985.

- LaserJet D+: LaserJet print engine and formatter but with 2 paper trays , 8 ppm, 300 dpi, $4,995, Spring 1986.

- LaserJet II: Preceding LaserJets were leveraged from the Canon PC-20 personal copier. However LaserJet II was designed from the ground up as a laser printer with correct order paper output . (Correct order means when you pick up the pages out of the printer they are in the same order as in your software file.) HP's version had a unique HP industrial design to differentiate it from Canon's version. PCL4 Language with improved features, more memory and fonts. 8 ppm, 300 dpi, $2,695, Spring 1987.

|

| The HP LaserJet II |

- LaserJet IID: Same as LaserJet II except 2 paper trays and first desktop laser printer with duplex (2 sided) printing . First LaserJet with an HP designed and manufactured Formatter. 8 ppm, 300 dpi, $4,295, Fall 1988.

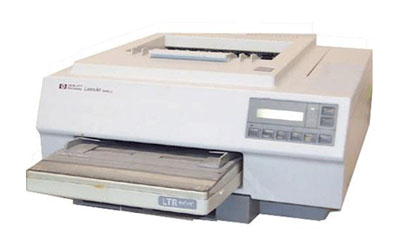

- LaserJet IIP: Worlds first "personal" laser printer, "No Ozone" print engine. 4 ppm, 300 dpi, $1,495, Fall 1989.

- LaserJet D+: LaserJet print engine and formatter but with 2 paper trays , 8 ppm, 300 dpi, $4,995, Spring 1986.

- LaserJet III: New version of LaserJet II engine with PCL5, scalable fonts, REt (Resolution Enhancement Technology) , HPGL and all new industrial design. REt gave perfectly (to the eye) smooth characters and graphics although the basic printer resolution remained 300 dpi. 8 ppm, 300 dpi, $2,395, Spring 1990.

- LaserJet IIID: Same as LaserJet III with the addition of 2 paper trays and duplex printing. 8 ppm, 300 dpi, $4,995, Fall 1990.

- LaserJet IIISi: Higher speed, high duty cycle, LAN connectivity with MIO. 17 ppm, 300 dpi, $5,495, Fall 1990.

- LaserJet IIP+: Higher performance, lower price version of LaserJet IIP. 4 ppm, 300 dpi, $1,249, Spring 1991.

- LaserJet PostScript Cartridge - PostScript printing for the LaserJet III and LaserJet IIP, $695, Fall 1991.

- LaserJet 4: New Canon engine with 600 dpi resolution and Microfine toner. Supports Microsoft TrueType scalable fonts. 8 ppm, 600 dpi, $2,199, Fall 1992.

- LaserJet 4Si: 600 dpi resolution. 17 ppm , 600 dpi, $3,749, Spring 1993.

- LaserJet 4L: New low cost print engine with "Instant On" fusing. 4 ppm, 300 dpi, $1,229, Spring 1993.

I could go on but I think by 1993 you can clearly see the following "more for less" trends:

- Midrange (8 ppm) LaserJets - From the first LaserJet to LaserJet 4, prices decreased from $3,495 to $2,199 while both software and hardware features increased dramatically.

- The LaserJet product line expanded to encompass two new market segments:

- Personal (4 ppm) LaserJet - Prices as low as $1,249.

- Network (17 ppm) LaserJet - Higher speed and duty cycle, network connected, priced almost as low as the original LaserJet but with much, much greater capability.

LaserJet sales greatly expanded as we drove prices down, performance up and entered new market segments. We shipped 1 million LaserJets by 1988. Sometime after the introduction of LaserJet II our order processing system came to a halt. Orders for that month had exceeded 99,999, the largest number Computer Group's order processing system would accept! The computer glitch was fixed and orders continued to climb. Total LaserJet sales had reached 100 million by 2006.

HP Printer Formatters/Controllers and LaserJet IID

The printer formatter (or controller) translates commands generated by the user's software application, describing what is to be printed, into the dots the laser actually puts on the page. We designed our own formatter for the HP 2680A, however the lack of resources and short schedules made this impractical for the next few laser products. For that reason Canon designed and manufactured the controllers for all LaserJet products up to and including LaserJet II.

By 1986 (LaserJet II) it had become increasingly clear that Canon's control over formatter design was greatly constraining HP's ability to add new features (e.g. higher levels of PCL, memory, processing power) at the rate we desired. At that time Doug Carnahan was Boise Division General Manager. He initiated a program to overcome this shortcoming by having HP design and manufacture all future LaserJet formatters. This was a bold step in that our next product (LaserJet IID) was scheduled to be released to manufacturing only 18 months later.

Fortunately LaserJet IID offered a relatively good entry point for HP designed and manufactured controllers. Although the schedule was short, the IID was projected to sell at only a few thousand per month. This would allow HP to exercise and perfect our design and manufacturing processes before we took on very high volume products like the follow-on LaserJet III.

The plan was that HP would manufacture controllers in Boise then ship them to Canon in Japan where they would be installed in the print engine to make a complete product. Canon required that our formatters have 99.97% reliability as delivered to their factory in Japan. This was an extremely aggressive goal and sometimes we wondered if they were just using it as a way to discourage us from supplying the formatters!

Doug Carnahan challenged Von Hansen and his team to complete the project in 18 months. Von and team took on the challenge even though the high performance PCL4 graphics in LaserJet IID required a new microprocessor plus a complex custom integrated circuit (The first one ever designed by Boise Division.). The formatter project was named 3A (Version 3A of multiple potential hardware architectures). To meet the schedule, Von's engineers took extreme measures such as canceling family vacations and in one case, a team member dropping out of graduate school. Von managed the project in the most organized fashion I've ever experienced. Detailed progress was measured on a weekly basis and resources reallocated as necessary to keep everything on track. Von's whole team pitched in and gave the effort everything they had.

To meet Canon's reliability goal Von implemented a rigorous design review process plus a special form of environmental testing that subjected the formatter to temperatures ramped from -50 to +100 degrees C and then back to -50 degrees over just a few minutes. The formatter was operating during all this so any failure could be detected and corrected. This test process proved extremely effective at exposing basic semiconductor as well as circuit design flaws.

While Von's team was scrambling to design the formatter, a similar crash program was taking place in manufacturing led by Steve Hager and his team. There was no precedent within HP for a factory that could manufacture printed circuits at the quality levels and volumes required for 3A. Steve's team did a lot of intense, pioneering work and was finally able to meet or beat all their manufacturing goals.

LaserJet IID was the first LaserJet where we had to integrate HP formatter development and manufacturing with Canon's engine development and manufacturing. To match Canon's aggressive engine schedule we needed a new way to coordinate HP R&D, manufacturing and marketing activities. So we formed a Program Management Team (PMT). This team was composed of one manager from each major part of the program who was able to make decisions for their group without normally having to consult a higher authority. This helped maximize overall coordination and shortened the schedule. The LJIID PMT approach proved to be so successful that we adopted it for all future LaserJet programs.

Through the hard work of Von's and Steve's teams, the LaserJet IID and 3A formatter programs were a complete success. Our formatter matched Canon's engine schedule, we met all quality, cost and performance goals and LaserJet IID shipped on schedule. From this point forward HP designed and manufactured all formatters used in LaserJet products, providing HP the following advantages:

- Gave HP more control over the timing and implementation of key differentiating features such as higher levels of PCL and REt..

- Significantly increased HP's added value and resulting profit.

The Consumables Business

In the early LaserJet days we were focused on selling printers. To do this, we felt we needed low cost toner cartridges to make the printer "cost per page" as competitive as possible. Canon did not agree with our strategy. They tended to charge HP more for toner cartridges than we thought prudent for selling printers. Canon's strategy was based on their years of experience selling copiers. They understood, much better than we did, that the toner business was an important part of the overall printer profit model.

It wasn't until about 1990, after we had sold several million LaserJets, that we formed an Operation (later a Division) responsible for our consumables business. From that point forward we put more emphasis on making money on toner even if it made printers a bit less competitive. The consumables group then expanded their product line to include paper. Their focus on making consumables a strong business for HP became an important part of the LaserJet evolution and overall business success.

Competition

Remember the management worry that HP's initial LaserJet success was just a "flash in the pan" and our business would evaporate as soon as Canon wanted to take it away? Well in more than 25 years Canon hasn't taken the business away from HP. One reason was that the LaserJet brand and market leadership was so commanding, that by the time Canon developed a dealer channel, there was almost no way to catch up with us. Another reason was that ongoing HP PCL enhancements and software support meant Canon's products were always at least one step behind ours. All this meant Canon could make more money selling print engines to HP than fighting us in the marketplace.

Actually the closest we ever came to losing significant LaserJet market leadership was probably from Lexmark. Lexmark was a spinoff from IBM in 1991 but kept the legal right to use the IBM logo for a number of years. The Lexmark engineers had years of experience in designing IBM copiers and had access to IBM copier technology and know-how. IBM had a patent cross license with Canon which was retained by Lexmark for all patents issued prior to the spinoff date. This meant Lexmark had access to many key Canon patents including the "all in one" toner cartridge. Lexmark engineers combined parts of an earlier design with the Canon "all-in-one" toner cartridge concept, made further improvements and introduced a very competitive series of products. The Lexmark products were well designed, had the IBM logo and were a very serious competitive threat for a number of years. An overview of Lexmark's version of the "All-In-One" cartridge can be seen at:

http://www.youtube.com/watch?v=PHxXmjxcAIo

Since Lexmark's cartridge concept is similar to Canon's, the video is quite applicable to LaserJet.

Dick Hackborn's View

An excerpt from a manuscript in the HP Company Archives based on a conversation with Dick Hackborn in Print Unchained3 page 164 gives his view of how the LaserJet business evolved :

"By the early 1980s, the Boise Idaho team had already gained a lot of experience in laser printers based on their own minicomputer system products. It was through their insight that the huge potential of a desktop laser printer was first recognized and subsequently turned into an immensely successful new business for HP. There was no backseat driving from me or Bill Hewlett or any of the corporate executives in Palo Alto. Boise set its own agenda with Canon, negotiated its own contracts, jointly did product definition with Canon, developed its own printer controllers, planned its marketing strategy (including distribution, a not uncontroversial item) and made the business happen."

- Timing - Canon: Reliable, low cost laser engine with toner cartridge leveraged from Canon's personal copier, availability of low cost CD player solid state lasers; PC market explosion; HP: Development of a PC dealer channel, HP Boise: PCL language (low cost, good performance, "just enough" functionality for the typical office user), technology and processes leveraged from earlier laser printer projects. - All these pieces came together at just the right time to design the right quick, quiet, quality product customers wanted for PC printing.

- Strong Canon/HP relationship. Starting with Bill Hewlett and Dr. T. Mitarai and including Hajime Mitarari and Don Hammond, T. Kitamura and the HP engineers/managers who interacted with Canon during HP2680A development.

- Canon culture - Many similarities with HP culture (ethics, honesty, quality, innovation, dedicated work force, people focus, respect, citizenship). This made for an excellent working relationship.

- HP Organizational/Divisional Structure:

- Enabled/forced Boise Division to purchase a very significant portion of the LaserJet product. Although the traditional HP business model historically suggested vertical integration, Boise Division had neither the resources nor time to design and manufacture our own print engines. We had to purchase them from an outside company.

- Boise Division was hungry for a successful printer product. It is unlikely that a division with a large, successful business would have gambled as much as we did on a new, unproved technology like laser printing. In our eyes, non-impact laser printing was the obvious technology for the print speeds, duty cycles and office environment required by our customers. During this time, Thermal Ink Jet was still too slow and had too many other problems (e.g. water fastness) to be viable. Being small and largely invisible to upper management probably helped us in successfully pursuing our laser printing vision.

Longer Term Business Success

- Canon/HP mutual dependence - In a relatively short period, the HP LaserJet had the brand recognition, market share and sales channel allowing us to move higher product volumes than anyone else. Canon would have had a hard time walking away from such a high volume customer. At the same time, Canon had by far the best laser print technology, reliability and manufacturing capability. HP could not have found another partner with the ability to deliver such a competitive product (except for those very brief periods when Canon fell behind).

- Continued HP investment (PCL: improved functionality, keep it a moving target), formatter (controller) hardware, software support, fonts, industrial design, innovative features, reliability, usability and "time-to-market." Constantly striving to deliver "more for less" and always keeping our product development in step with Canon's engine development (We called this "drinking from the Canon fire hose.")

- Continued strong Canon investment in laser engine technology and manufacturing, driving engine costs down and performance up. Major innovations such as "instant-on" fusing, roller charging and transfer, 600 dpi resolution, micro-fine toner.

- The right business model at both HP and Canon for a successful non-vertically integrated business.

Acknowledgements

I wish there were some way to list all the people who contributed to HP's success in laser printing. Ray Smelek clearly played a major role by continuing to support laser printer development even after our first two failures. Don Hammond consistently supported our efforts and worked to strengthen the Canon/HP relationship.

Key architects for the HP 2680A included Jim Langley, Bob Hay, Bill Robison and Phil Gordon. I've already mentioned Von Hansen's leadership with PCL/formatters, Roger Archibald's role as project manager for the first LaserJet and Steve Hager's leadership in formatter manufacturing. However there are literally hundreds of other people who played key roles in LaserJet's success over the years and it is downright impossible to name all of them. So all I can do is to just say "Thank you for a job well done. Your dedication and hard work allowed us to accomplished what most "pundits" said was impossible"

A special vote of thanks to John Minck who encouraged me to write this history and edited the final result. John was a long time HP employee (joined HP long before me), knew Bill Hewlett and Dave Packard personally, served in multiple management and marketing roles including the LED Dept. Manager in the HPA Division that supplied LED displays for HP calculators and instruments in their early days. John and I crossed paths at HP Microwave Division in 1975 and have remained friends since.

Boise, Idaho

May, 2011

Jim Hall

Notes:

- 1 - Charles House and Raymond Price, The HP Phenomenon – Innovation and Business Transformation (Stanford University Press, 2009)

- 2 - Ray Smelek, Ray Smelek - Making My Own Luck (Claxton Printers, Caldwell, ID)

- 3 - Edward Webster, Print Unchained (DRA of Vermont, Inc, 2000)

- 4 - Good additional historical information on the early LaserJet product line can be found at the HP Computer Museum web site

- 5 - Dick Hackborn was General Manager of Disc Memory Division (DMD) when it moved to Boise in 1976. In 1980 he became responsible for the Computer Peripherals Group which included Disc Memory, Vancouver, Greeley and Boise Divisions. In 1984 his role was expanded to also include San Diego, Corvallis and Bristol (UK) Divisions.

|

Cover of June 1982, Hewlett-Packard Journal Courtesy of the Hewlett-Packard Company |

The June 1982 issue of the Hewlett Packard Journal

The June, 1982 edition of the Hewlett-Packard Journal was entirely dedicated to the HP 2680A. The eight articles are reproduced here:

- Laser Printing System Provides Flexible, High-Quality, Cost-Effective Computer Output

- Laser Printing System Architecture

- Interactive Software for Intelligent Printers

- Electrostatic Image Forming in a Laser Printer

- Laser Printer Image Development System

- Laser Printer Fusing System

- Monitoring the Laser Printing Process

- Specialized High-Speed Electronics for Document Preparation Flexibility

|

Cover of July 1982, Hewlett-Packard Journal Courtesy of the Hewlett-Packard Company |

The July 1982 issue of the Hewlett Packard Journal

Five articles of the June 1982 edition of the Hewlett-Packard Journal were dedicated to the HP 2680A. They are reproduced here:

- Optical System Design for the Laser Printing System

- Laser Printer Optics Control and Diagnostic Circuit

- A Synchronous Mirror-Motor Drive for the Laser Printer

- Laser Printer Machine Control System

- Sensing Paper Jams