to Dynac a year or so later. John Hasen came aboard as a project engineer, and Truman Boston joined to test the Bendix system. Truman and another technician moved into a small room which was closed up for classified work. "The door into the room was always closed so you couldn't see anything that was going on, and the room didn't have any PA system or phone. One day while we were in there, there was a fire in the machine shop right across the aisle from us. We heard all the bells and people, of course, but we didn't know what was going on. We really tore out of there when the fire trucks came."

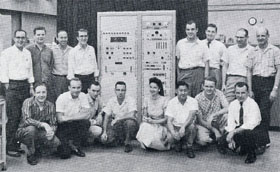

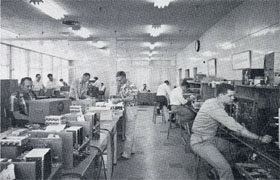

Exact dates have a tendency to get lost with time, but in the ensuing few months, the company got larger. June Hall joined to load PC boards, Myrtle McClintock set up pre-fab, and Christine Drysdale provided necessary extra help in production. June remembers, "the close feeling, working together with a small group." Myrt remembers, "the confusion after so much order at -hp-." (She now sees more order.)

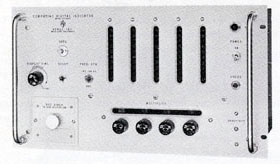

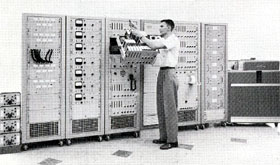

The product line grew. Six or seven months after Dynac's founding, new engineering projects were afoot and the company needed more people. Bob Knapp joined engineering and became Dynac's first direct hire (all other employees were -hp- transfers). He worked on the 5001 Boeing Wind Tunnel System. Nellie Monsees remembers Bob needing a breadboard of one of the system components. He gave Nellie a schematic and a box of parts and said, "go!' Nellie, of course, was used to -hp-'s wiring sample technique and didn't read schematics. She didn't want to look uneducated to this new-hire so she took a quick course in schematic reading from Humphries and Hasen and finished her first breadboard.

Don Loughry, our Engineering Manager, joined Dynac as the test group in the fall of 1956. A special jet engine test set for Northrup was his first assignment. One of Don's vivid recollections is taking inventory with George Climo and a bunch of other guys on Christmas Eve.

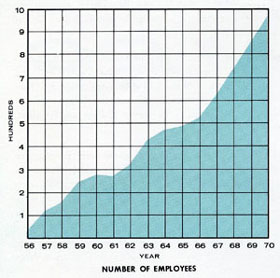

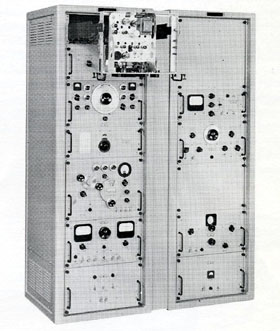

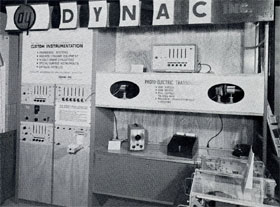

New "standard special instruments" were set up for production. The 5003 X-Band Test Set, 2200 Oscillator for Ling, and the 207 Oscillator were put into the mill, more special systems were contracted and built . . . and the Dynac operation grew. Rose Carson and Ven Franco remember working with early Dynac products, although they did not join the payroll until 1957 when Dynac was over 1 year old. Ven's first recollection of Dynac is the Christmas Party in the Redwood Building. "It was a lot of fun. We used to work hard too, anywhere from 10 to 12 hours a day trying to meet our schedules." Rose tells the story about the crash when a customer wanted something extra engraved on a system front panel at the last minute. "The engraving machine had to be brought to the hardware because the system was a special and everything was already finished and in place and painted, and ready to ship out the door. The engineers were there helping to hold everything in place, and we did get the shipment out on time." In the early months of 1957 Byrd Beh became the first person assigned to the Dynac sales department full time. Shortly after Byrd began doing contract and correspondence work, Ed Morgan (later to become Sales Manager) started sharing his time between Dynac sales, —hp—, and the U.S. Army. |

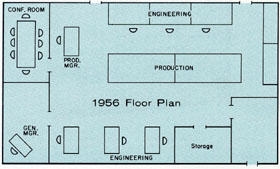

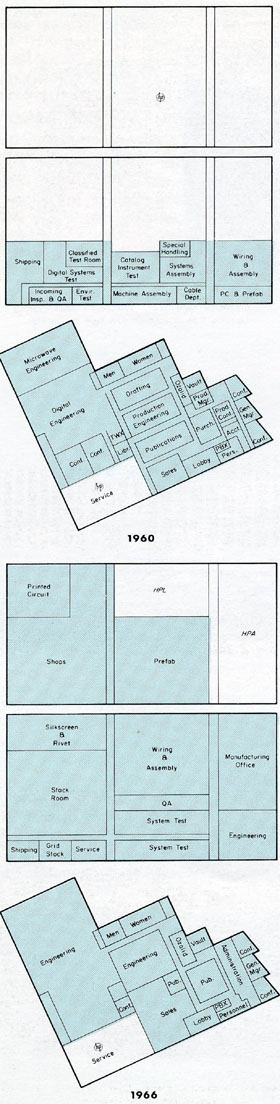

As Dynac got larger, job functions became more specialized. Beg, borrow, and boondoggle policies regarding equipment, parts, and manpower became less of a way of life. Dynac got more organized and in mid-1957 even incorporated. At about the time of the incorporation, physical expansion was taking place. Dynac took over the entire Redwood Building, which added 5,000 square feet of floor space to the existing 1,500. Bob Grimm remembers this expansion as, "All of a sudden people could move around again!' Bob Knapp remembers being cooped-up in the one little room in the Redwood Building . . . "The whole Dynac engineering, production, and administration staff, and then in about November —hp— vacated the room next door for us. The floor got polished one day and I recall Bob Rawlins saying it would be a great place to have a dance. So, that night, the Dynac employees and their wives or girl friends and some —hp— people were invited to a dance in that area. A punch bowl was brought in and I can recall Bruce Wholey and Ed van Bronkhorst pouring the Vodka and one of the gals pouring the orange juice. We had a great time that night!'

We also gained a second building on Olive Street. This building was given the magnificent name, "Dynac Plant Two," and at this site, the 2500s, 207s and 2000s were produced. Subsequent moves put Dynac people into the "Pepper Street Building" the stockroom at the corner of Park and Lambert, and other buildings on Park.

Early Dynac, with a population of some forty people, was supported in the field by a sales staff in excess of 100 people. Dynac was never at a loss for good ideas and suggestions on products to invent and manufacture. Sales get-togethers were extremely active exchanges of ideas on what Dynac really should build.

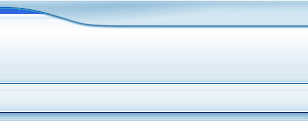

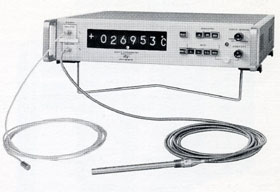

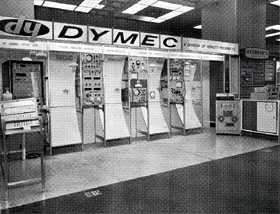

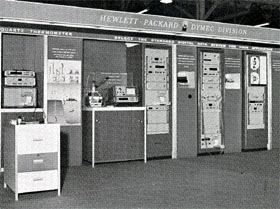

Soon the Dynac name was changed to Dymec, and a year later the independent company became a division of Hewlett-Packard. Dynac got its own personnel department in early 1959. Prior to this time everyone did his own hiring. The organization structure got its first major change in 1960 when Cort Van Rensselaer took Dymec's reins as General Manager. The products gained additional standardization. In June 1960 Dymec engineering and administration groups moved from the Redwood Building to the present "sawtooth" building (Bldg. 8). Additional facilities were added; we expanded and became more efficient, more profitable.

General Managership changed again in February 1961 when Bob Grimm succeeded Cort who moved to manage the 'Scope Division. Bob's manufacturing position was filled by Vic Buell, then Karl Schwarz, and most recently Frank Wheeler. While the past is of interest, the future holds at least equal interest. Many of the people who helped mold Dymec's character are still here and elsewhere in the —hp— organization. The company outlook has varied from dreary to excellent, but the record of accomplishment is one to be proud of ... and the feeling at Dymec is a proud one. The future of the company is in its capacity for accomplishment, and this is Dymec's strong suit. |